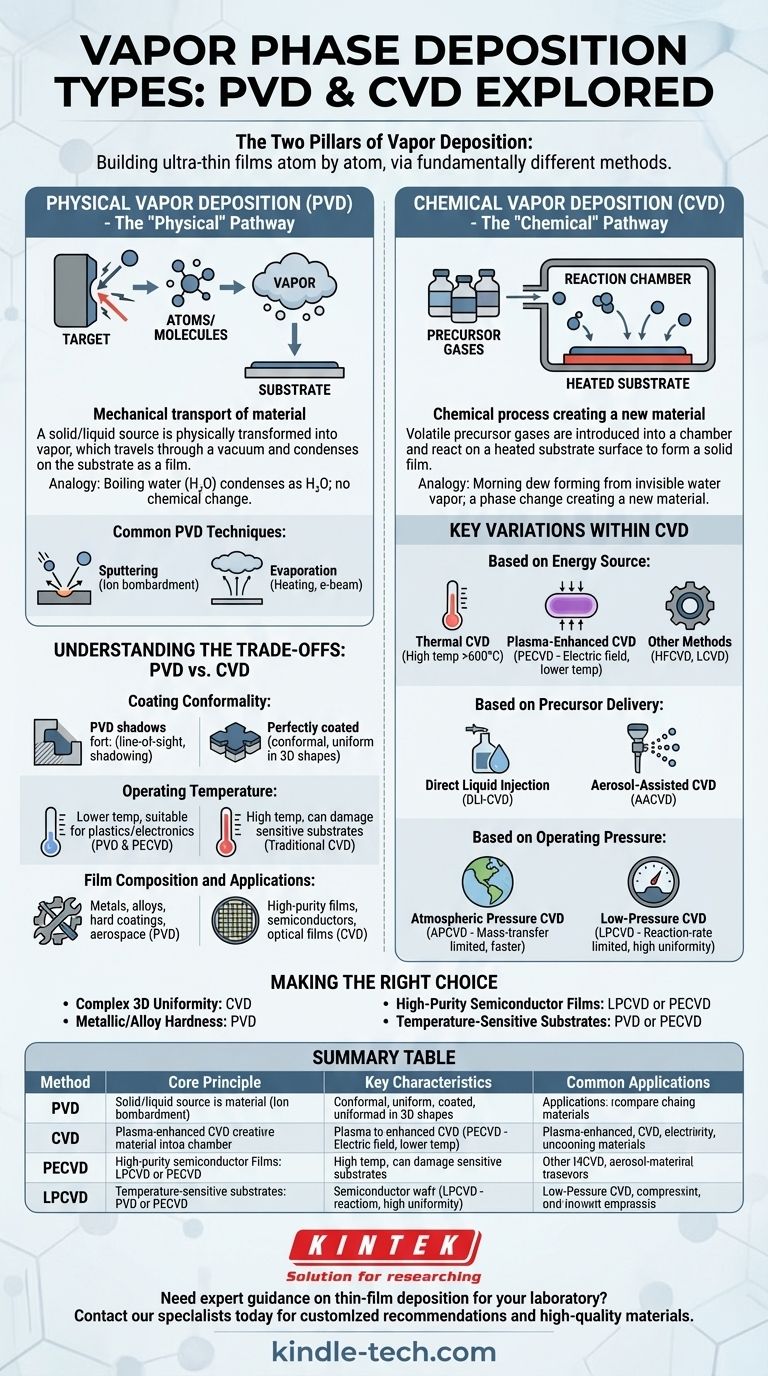

At its core, vapor deposition is divided into two fundamental families. These are Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD). While both techniques build materials one atom or molecule at a time to create ultra-thin films, their methods for doing so are fundamentally different, defining their unique strengths and applications.

The crucial distinction is this: Physical Vapor Deposition (PVD) is a mechanical process that transports a material, while Chemical Vapor Deposition (CVD) is a chemical process that creates a new material directly on the target surface. Understanding this difference is the key to selecting the right technology for your goal.

The Two Pillars of Vapor Deposition

To truly grasp the landscape, you must first understand the foundational difference between PVD and CVD. Think of it as the difference between moving sand with a shovel versus creating sandstone from a chemical reaction.

Physical Vapor Deposition (PVD): The "Physical" Pathway

PVD is a line-of-sight process where a solid or liquid source material, called a "target," is physically transformed into a vapor. This vapor then travels through a vacuum or low-pressure environment and condenses on the substrate as a thin film.

The process is analogous to boiling water: the water itself (H₂O) is turned into vapor and then condenses on a cool surface, still as H₂O. No chemical change occurs.

Common PVD techniques include sputtering, where ions bombard the target to eject atoms, and evaporation, where the target is heated until its atoms vaporize, such as in e-beam evaporation.

Chemical Vapor Deposition (CVD): The "Chemical" Pathway

CVD involves introducing one or more volatile precursor gases into a reaction chamber. These gases decompose and react on a heated substrate surface, forming a solid thin film.

This is a true chemical transformation. The final film is a new material, distinct from the precursor gases. Think of how morning dew (liquid water) forms from invisible water vapor in the air—a phase change creating a "film" on the grass.

The result is a highly uniform and often very pure material, as the chemical reaction is precise and controlled.

Key Variations Within Deposition Methods

Within the two main families, especially CVD, numerous variations exist, each tailored for specific materials, substrates, and outcomes. These subtypes are typically defined by how energy is supplied, how precursors are delivered, or the operating pressure.

Based on Energy Source

The energy used to drive the chemical reaction is a primary differentiator in CVD.

- Thermal CVD: This is the classic method, using high temperatures (often >600°C) to provide the thermal energy needed for the precursor gases to react.

- Plasma-Enhanced CVD (PECVD): This method uses an electric field to generate a plasma. The high-energy plasma provides the energy for the reaction, allowing deposition at much lower temperatures.

- Other Methods: Techniques like Hot-Filament CVD (HFCVD) and Laser CVD (LCVD) use a heated wire or a focused laser beam, respectively, to supply localized energy for the reaction.

Based on Precursor Delivery

How the chemical precursor gets to the reaction chamber also defines the process.

- Direct Liquid Injection (DLI-CVD): A liquid precursor is precisely injected into a heated vaporization zone before entering the main chamber as a gas.

- Aerosol-Assisted CVD (AACVD): A liquid precursor is first turned into a fine aerosol mist, which is then transported into the heated chamber for deposition.

Based on Operating Pressure

The pressure inside the reaction chamber has a profound impact on the film's properties.

- Atmospheric Pressure CVD (APCVD): Performed at normal atmospheric pressure, this process is often mass-transfer limited, meaning the deposition rate is governed by how fast precursor gases can travel to the substrate. It's often faster and simpler for large-scale production.

- Low-Pressure CVD (LPCVD): Performed in a partial vacuum, this process is reaction-rate limited. The abundance of precursor gas means the deposition rate is governed by the speed of the chemical reaction on the surface itself, resulting in excellent film uniformity and conformality.

Understanding the Trade-offs: PVD vs. CVD

Choosing between PVD and CVD requires weighing their inherent advantages and disadvantages for your specific application.

Coating Conformality

CVD excels at producing conformal coatings, meaning the film grows with uniform thickness over complex, three-dimensional shapes and inside trenches or pores.

PVD is a line-of-sight process. Surfaces not directly facing the source material receive little to no coating, creating a "shadowing" effect.

Operating Temperature

Traditional thermal CVD requires very high temperatures that can damage sensitive substrates like plastics or certain electronics.

PVD and Plasma-Enhanced CVD (PECVD) can operate at significantly lower temperatures, making them suitable for a wider range of materials.

Film Composition and Applications

PVD is exceptionally well-suited for depositing metals, alloys, and some ceramic compounds. It's widely used for hard, corrosion-resistant coatings on tools and dense, temperature-resistant films for aerospace components.

CVD is the go-to method for creating extremely high-purity, stoichiometric films like silicon dioxide or silicon nitride for the semiconductor industry. It is also used for creating optical films.

Making the Right Choice for Your Application

Your specific goal will guide your decision. Consider the primary requirement of your project to determine the best path forward.

- If your primary focus is coating a complex 3D object uniformly: CVD is the superior choice due to its excellent conformality.

- If your primary focus is depositing a metallic or alloy coating on a tool for hardness: PVD is a highly effective and common industry standard.

- If your primary focus is depositing a high-purity dielectric film on a semiconductor wafer: A form of CVD, likely LPCVD or PECVD, is the necessary technology.

- If your primary focus is coating a temperature-sensitive plastic or electronic component: A lower-temperature process like PVD or Plasma-Enhanced CVD (PECVD) is required.

By first identifying whether your need is physical transport or chemical creation, you can confidently navigate the complex world of thin-film deposition.

Summary Table:

| Method | Core Principle | Key Characteristics | Common Applications |

|---|---|---|---|

| Physical Vapor Deposition (PVD) | Mechanical transport of material | Line-of-sight process, lower temperatures, metallic/alloy coatings | Tool coatings, aerospace components, decorative finishes |

| Chemical Vapor Deposition (CVD) | Chemical reaction creates new material | Excellent conformality, high purity films, often requires high temperatures | Semiconductor devices, optical coatings, uniform 3D coatings |

| Plasma-Enhanced CVD (PECVD) | Plasma-driven chemical reaction | Lower temperature operation, good step coverage | Temperature-sensitive substrates, electronics manufacturing |

| Low-Pressure CVD (LPCVD) | Vacuum environment reaction | Superior film uniformity, reaction-rate limited | High-purity dielectric films, semiconductor manufacturing |

Need expert guidance on thin-film deposition for your laboratory?

At KINTEK, we specialize in providing precision lab equipment and consumables for all your vapor deposition needs. Whether you're working with PVD systems for metallic coatings or CVD reactors for semiconductor applications, our experts can help you select the right technology for your specific requirements.

We provide:

- Customized deposition system recommendations

- High-quality targets and precursor materials

- Technical support for optimal process development

- Solutions for research, development, and production scales

Contact our deposition specialists today to discuss how we can enhance your thin-film research and manufacturing capabilities with the right equipment and consumables for your laboratory.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis

- What are the advantages of using HFCVD for BDD electrodes? Scaling Industrial Diamond Production Efficiently

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- How are reactants introduced into the reaction chamber during a CVD process? Mastering Precursor Delivery Systems