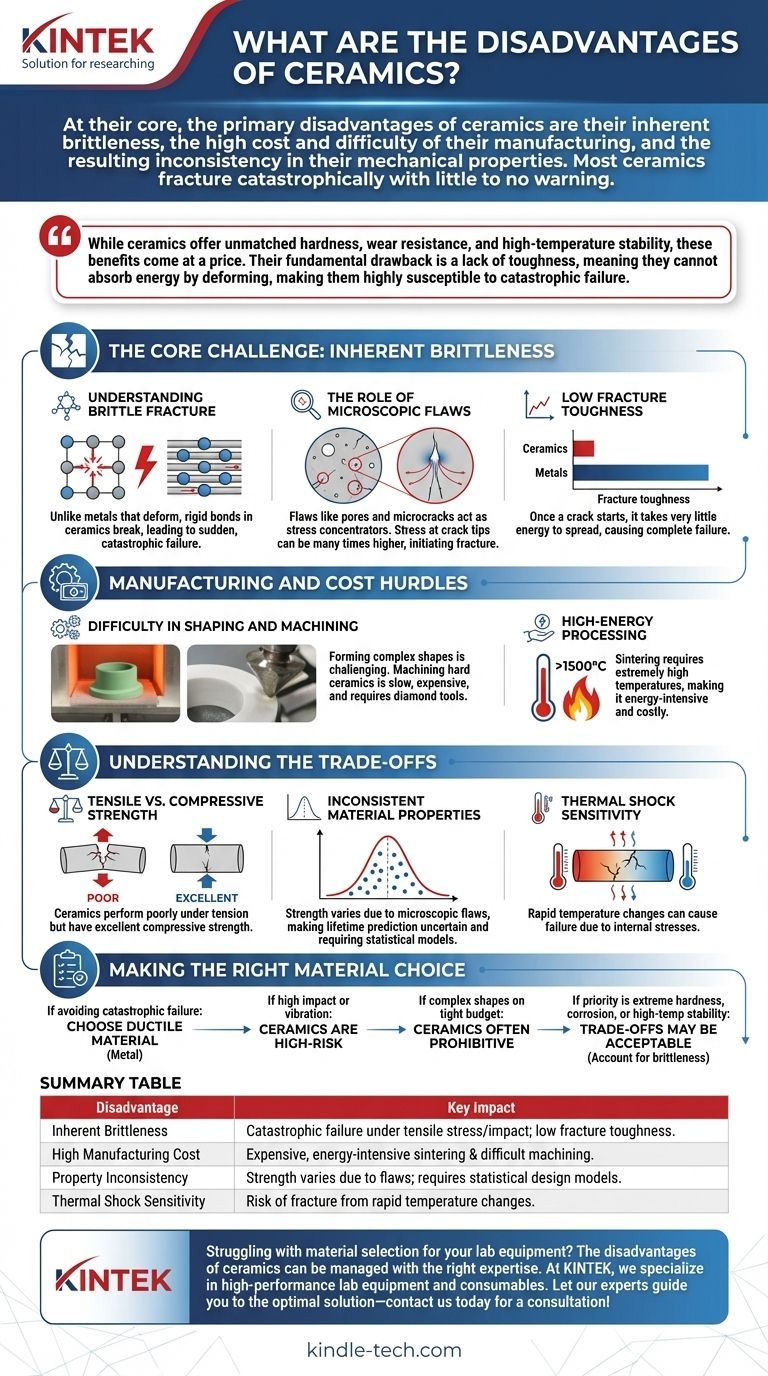

At their core, the primary disadvantages of ceramics are their inherent brittleness, the high cost and difficulty of their manufacturing, and the resulting inconsistency in their mechanical properties. Unlike metals that bend and deform under stress, most ceramics fracture catastrophically with little to no warning, which is their most significant engineering limitation.

While ceramics offer unmatched hardness, wear resistance, and high-temperature stability, these benefits come at a price. Their fundamental drawback is a lack of toughness, meaning they cannot absorb energy by deforming, making them highly susceptible to catastrophic failure from impacts or microscopic flaws.

The Core Challenge: Inherent Brittleness

The most defining disadvantage of any traditional ceramic is its brittleness. This property is a direct result of its strong ionic and covalent atomic bonds.

Understanding Brittle Fracture

Unlike the metallic bonds in metals, which allow atoms to slide past one another (plastic deformation), the rigid bonds in ceramics resist any movement.

When enough stress is applied, these bonds break entirely rather than shifting. This results in a crack that propagates rapidly through the material, leading to sudden, catastrophic failure.

The Role of Microscopic Flaws

Ceramic manufacturing processes inevitably introduce tiny flaws like pores, microcracks, or grain boundaries. These imperfections act as stress concentrators.

Under a load, the stress at the tip of one of these microscopic cracks can be many times higher than the overall stress on the part. When this localized stress reaches a critical point, a fracture begins.

Low Fracture Toughness

Engineers measure a material's resistance to crack propagation using a property called fracture toughness. Ceramics have notoriously low fracture toughness compared to metals.

This means that once a crack starts, it takes very little energy to make it spread through the entire component, causing complete failure.

Manufacturing and Cost Hurdles

The same hardness that makes ceramics desirable for wear resistance also makes them exceptionally difficult and expensive to produce.

Difficulty in Shaping and Machining

Forming complex ceramic shapes is challenging. Most parts are first created in a "green" state from powders, which are then fired at high temperatures in a process called sintering.

Once fired, the material becomes extremely hard. Any final machining or grinding to achieve tight tolerances is a slow, specialized, and expensive process that requires diamond-tipped tools.

High-Energy Processing

The sintering process required to densify ceramic powders and fuse them into a solid part requires extremely high temperatures, often over 1,500°C (2,700°F).

This is a highly energy-intensive process, contributing significantly to the overall cost of the final component.

Understanding the Trade-offs

The disadvantages of ceramics are not always dealbreakers. The key is understanding when they pose the greatest risk to your application.

Tensile vs. Compressive Strength

Ceramics perform poorly under tension (pulling forces) because it pulls microscopic flaws open, encouraging cracks to form and spread.

However, they have excellent compressive strength. When compressed, cracks are forced closed, preventing them from propagating. This is why ceramics are used successfully in applications with purely compressive loads.

Inconsistent Material Properties

Because failure depends on the random distribution and size of microscopic flaws, the measured strength of ceramic parts can vary significantly from one piece to the next.

This statistical nature of ceramic strength makes component lifetime prediction less certain than for metals. Engineers must use specific statistical models (like Weibull analysis) to design reliable ceramic components, adding complexity to the design process.

Thermal Shock Sensitivity

While many ceramics can withstand extremely high temperatures, they can be vulnerable to thermal shock—failure caused by rapid temperature change.

If one part of a ceramic component heats or cools faster than another, the internal stresses can be enough to initiate a fracture. This limits their use in applications with severe and rapid thermal cycling.

Making the Right Material Choice

Evaluating these disadvantages against your specific goals is critical for proper material selection.

- If your primary focus is avoiding catastrophic failure: A ductile material like metal is a safer choice, unless you can design the system to keep the ceramic part purely in compression.

- If your application involves high impact or vibration: The inherent brittleness and low fracture toughness of ceramics make them a high-risk choice.

- If you require complex shapes on a tight budget: The manufacturing and machining costs for complex ceramic parts are often prohibitive compared to metals or polymers.

- If your priority is extreme hardness, corrosion, or high-temperature stability: The disadvantages of ceramics may be an acceptable trade-off, provided the design meticulously accounts for their brittleness and sensitivity to tensile stress.

Understanding these fundamental limitations is the first step toward leveraging the unique strengths of ceramic materials effectively.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Inherent Brittleness | Catastrophic failure under tensile stress or impact; low fracture toughness. |

| High Manufacturing Cost | Expensive, energy-intensive sintering and difficult machining with diamond tools. |

| Property Inconsistency | Strength varies due to microscopic flaws; requires statistical design models. |

| Thermal Shock Sensitivity | Risk of fracture from rapid temperature changes. |

Struggling with material selection for your lab equipment? The disadvantages of ceramics can be managed with the right expertise and components. At KINTEK, we specialize in high-performance lab equipment and consumables, helping you navigate material trade-offs for durability, temperature resistance, and cost-efficiency. Let our experts guide you to the optimal solution—contact us today for a consultation!

Visual Guide

Related Products

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Head Tweezers with Pointed Elbow Zirconia Ceramic Tip

- Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

People Also Ask

- What are alloys in simple words? Unlock the Power of Engineered Materials

- Why are high-purity zirconia grinding balls recommended for LATP ceramic powders? Ensure Purity and High Conductivity.

- Why are zirconia grinding balls preferred for NiCrAlY-Mo-Ag powders? Ensure Maximum Purity and Durability

- What are the applications of zirconia ceramics? Unlock High-Performance Solutions for Extreme Environments

- Why are zirconia grinding balls recommended for sulfide solid electrolytes? Essential Tips for High Purity Milling