While highly effective for creating uniform density, cold isostatic pressing (CIP) is not without its operational and practical limitations. Its primary disadvantages are a lack of precise dimensional accuracy, slower cycle times compared to other pressing methods, and the creation of a "green" part that requires subsequent sintering and machining to achieve final specifications.

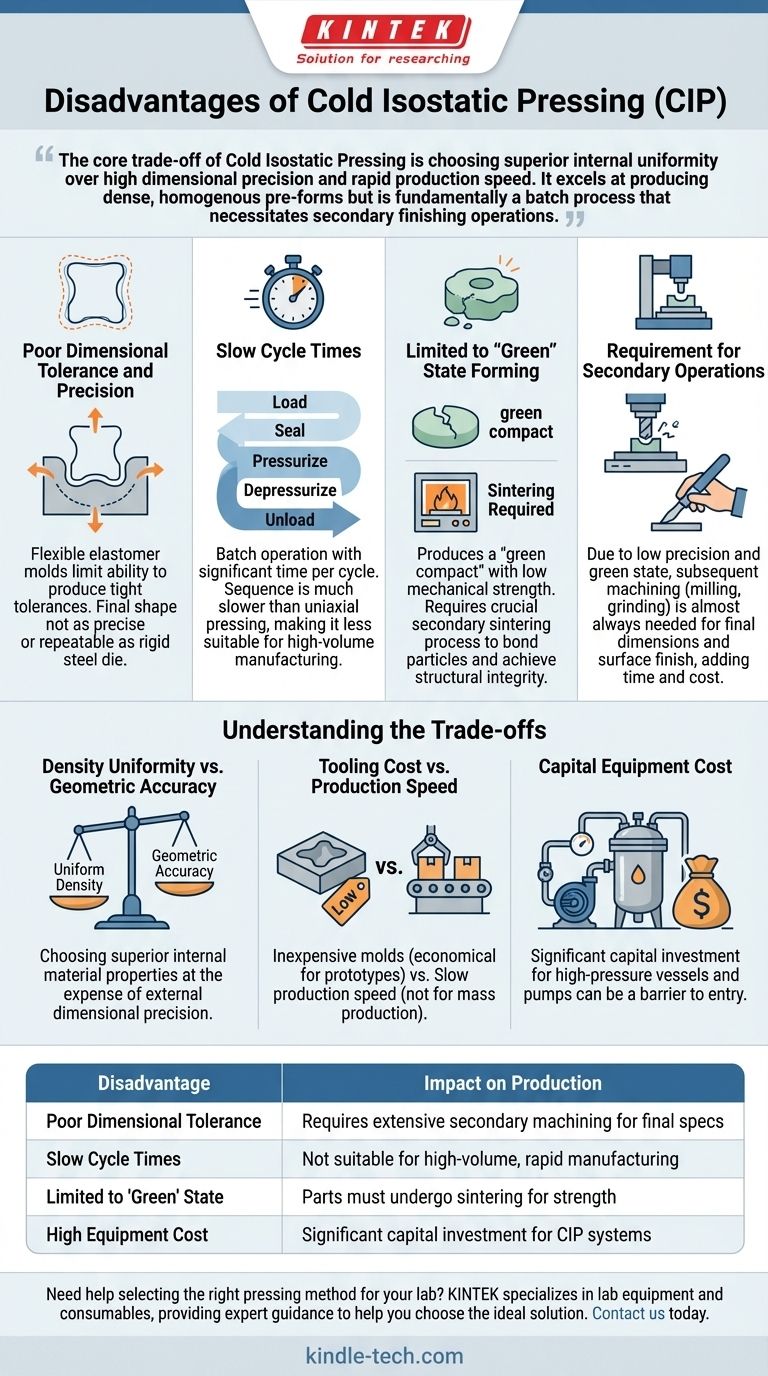

The core trade-off of Cold Isostatic Pressing is choosing superior internal uniformity over high dimensional precision and rapid production speed. It excels at producing dense, homogenous pre-forms but is fundamentally a batch process that necessitates secondary finishing operations.

The Fundamental Limitations of the CIP Process

Cold isostatic pressing achieves its uniform density by applying equal pressure from all directions via a fluid. This very mechanism, however, introduces several key disadvantages that you must consider when evaluating it as a manufacturing method.

Poor Dimensional Tolerance and Precision

The use of a flexible elastomer mold is central to the CIP process. This mold transfers the hydraulic pressure uniformly to the powder within it.

However, this flexibility inherently limits the process's ability to produce parts with tight dimensional tolerances. The final shape of the "green" compact will not be as precise or repeatable as one formed in a rigid steel die.

Slow Cycle Times

The CIP process is a batch operation. It involves loading the powder into the mold, sealing it, placing it in the pressure vessel, filling the vessel with fluid, pressurizing, depressurizing, and finally unloading.

This sequence is significantly slower than methods like uniaxial (die) pressing, where parts can be compacted in a matter of seconds. This makes CIP less suitable for high-volume manufacturing where speed is a critical factor.

Limited to 'Green' State Forming

The part that comes out of the CIP vessel is known as a "green compact." While it is uniformly dense, it has very low mechanical strength—often compared to a piece of chalk.

This green part is an intermediate product. It cannot be used for any structural application without a crucial secondary process, typically sintering, to bond the powder particles together.

Requirement for Secondary Operations

A direct consequence of the low precision and green state is the near-universal need for secondary operations.

After sintering, which can cause further dimensional changes, the part almost always requires machining (milling, grinding, turning) to achieve the final required dimensions, surface finish, and geometric features. These additional steps add time and cost to the overall production process.

Understanding the Trade-offs

Choosing a manufacturing process is about understanding its compromises. The disadvantages of CIP are best understood as the trade-offs made to achieve its primary benefits.

Density Uniformity vs. Geometric Accuracy

CIP delivers a homogenous density throughout the part, which is extremely difficult to achieve with other methods. This minimizes weak spots and prevents cracking during sintering.

The trade-off is a lack of geometric accuracy. You are choosing superior internal material properties at the expense of external dimensional precision in the as-pressed state.

Tooling Cost vs. Production Speed

The elastomer molds used in CIP are very inexpensive to produce compared to the hardened steel dies required for uniaxial pressing. This makes CIP economical for prototypes, small production runs, or very large parts.

The trade-off for this low tooling cost is slow production speed. For mass production, the higher initial investment in a steel die is justified by a much lower per-part processing time.

Capital Equipment Cost

While the tooling (molds) is cheap, the CIP equipment itself represents a significant capital investment. High-pressure vessels designed for severe cyclic loading and the associated high-pressure pumps are complex and expensive.

This high initial equipment cost can be a barrier to entry, especially for smaller operations.

Making the Right Choice for Your Application

The decision to use CIP depends entirely on your project's primary objective. Analyzing its disadvantages allows you to select it for the right reasons.

- If your primary focus is achieving maximum material density and uniformity: CIP is an excellent choice for creating high-integrity pre-forms that will be machined to their final shape later.

- If your primary focus is high-volume production of simple shapes with tight tolerances: A different method like uniaxial die compaction is almost certainly more cost-effective and appropriate.

- If your primary focus is creating a large or complex initial shape without investing in expensive hard tooling: CIP provides unmatched flexibility, but you must budget for significant post-processing.

Ultimately, understanding these disadvantages allows you to leverage Cold Isostatic Pressing for its intended purpose: producing superior material pre-forms, not finished parts.

Summary Table:

| Disadvantage | Impact on Production |

|---|---|

| Poor Dimensional Tolerance | Requires extensive secondary machining for final specs |

| Slow Cycle Times | Not suitable for high-volume, rapid manufacturing |

| Limited to 'Green' State | Parts must undergo sintering for strength |

| High Equipment Cost | Significant capital investment for CIP systems |

Need help selecting the right pressing method for your lab? KINTEK specializes in lab equipment and consumables, providing expert guidance to help you choose the ideal solution for your material processing needs. Whether you're working with prototypes or high-volume production, our team ensures you get the right equipment for superior results. Contact us today to optimize your lab's efficiency!

Visual Guide

Related Products

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

People Also Ask

- Why is cold isostatic pressing applied following steel mold dry pressing in 8YSZ? Enhance Density and Crack Prevention

- Why is a Cold Isostatic Press (CIP) Required for NaSICON? Achieve Maximum Green Density and Ionic Conductivity

- Why is an isostatic press used for solid electrolyte pellets? Achieve Maximum Density for Accurate Ionic Conductivity

- What is the pressing method in ceramics? A Guide to Shaping Dense, High-Performance Parts

- What is the meaning of isostatic pressing? Achieve Uniform Density in Complex Parts

- What advantages does a Cold Isostatic Press (CIP) offer for solid-state batteries? Superior Density & Uniformity

- What temperature is cold isostatic pressing? A Guide to Room-Temperature Powder Compaction

- What is a cold press machine? A Guide to Uniform Powder Compaction Without Heat