To be clear, the primary disadvantages of furnace brazing are not failures of the process itself, but rather strict requirements that must be met in design and process control. Its main limitations include the necessity for very close joint clearances, the unavoidable annealing (softening) of the entire assembly, and the need for part designs that specifically accommodate the placement of the brazing filler metal.

The core challenge of furnace brazing is its lack of forgiveness. The process delivers exceptional results when part design, joint fit-up, and thermal cycles are precisely controlled, but it can easily fail if these prerequisites are not met.

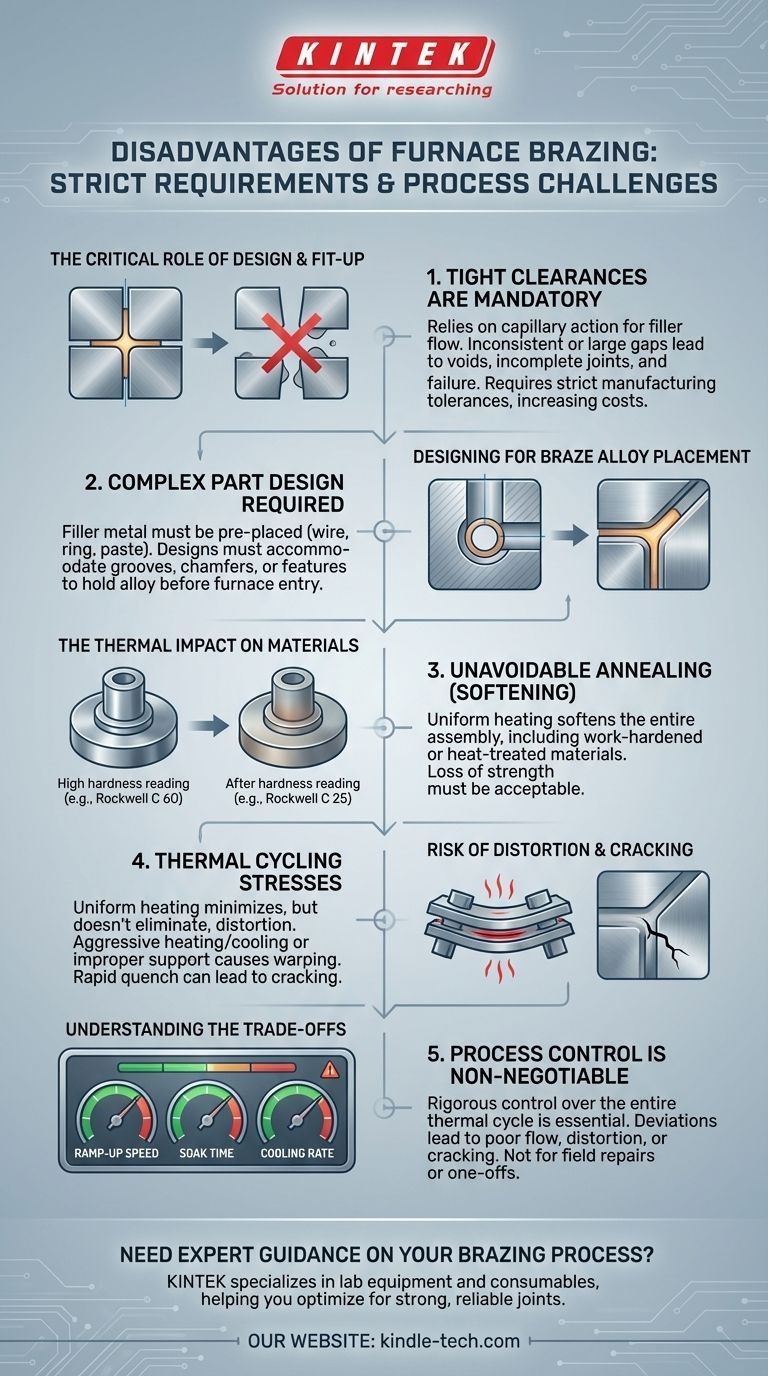

The Critical Role of Design and Fit-Up

While furnace brazing produces strong and clean joints, this outcome is entirely dependent on upfront engineering. The design of the components is as critical as the brazing process itself.

The Necessity for Tight Clearances

Furnace brazing relies on capillary action to draw the molten filler metal into the joint. This physical phenomenon only works effectively across very small, uniform gaps.

If the clearance between parts is too large or inconsistent, the filler metal will not flow properly, resulting in voids, incomplete joints, and a failed assembly. This requires tight manufacturing tolerances, which can increase machining costs.

Designing for Braze Alloy Placement

You cannot simply apply the braze alloy at the last minute. It must be placed at the joint before the assembly enters the furnace, typically as a wire, ring, paste, or shim.

Your part design must account for this. It often requires adding grooves, chamfers, or specific features to hold the filler metal in the correct position so that gravity and capillary action will draw it into the joint when it melts.

The Thermal Impact on Materials

Heating the entire assembly to brazing temperature has significant, unavoidable consequences on the properties of the base materials.

Inevitable Annealing of Components

The furnace heats the whole part, not just the joint area. This uniform heating cycle will anneal, or soften, any materials that were previously heat-treated or work-hardened to achieve a higher strength.

This loss of hardness must be acceptable for the final product's function. In some cases, the brazing cycle can be combined with a hardening cycle, but this requires complex process control and compatible materials.

Risk of Thermal Distortion

While uniform heating generally minimizes distortion compared to localized methods like welding, the risk is not zero. If components are not properly supported or if the heating and cooling rates are too aggressive, distortion can still occur.

Assemblies must be thermally stable throughout the cycle to ensure the braze alloy flows correctly into joints that remain consistent.

Potential for Quench Cracking

If the cooling phase (quench) is too rapid, it can introduce immense stress into the newly formed joint. This can lead to quench cracking, where the braze joint or the adjacent base metal fractures.

Controlling the cooling rate is a delicate balance, especially if you are also trying to achieve a specific hardness in the parent material.

Understanding the Trade-offs

Furnace brazing is an industrial process with specific constraints that make it unsuitable for certain applications.

Process Control is Non-Negotiable

Successful furnace brazing depends on rigorous control over the entire thermal cycle. The ramp-up speed, the time spent at temperature, and the cooling rate must all be managed precisely.

Any deviation can lead to the issues mentioned above, including poor braze flow, distortion, or cracking. This is not a "forgiving" process that can be easily adjusted on the fly.

Not Suitable for Field Repairs or One-Offs

Furnace brazing is, by its nature, a factory-based process. It requires large, stationary equipment and cannot be used for on-site repairs or for joining single, unique assemblies in a cost-effective manner.

Methods like torch brazing or welding are far more practical for low-volume or portable applications.

Less Effective for Very Thick Sections

While it excels at joining complex assemblies, the uniform heating of furnace brazing can be time-consuming and energy-intensive for very large or thick-walled components. Localized heating methods are often more efficient in those scenarios.

Making the Right Choice for Your Application

Evaluate furnace brazing based on its strict requirements, not just its potential benefits.

- If your primary focus is joining heat-sensitive or work-hardened components: Be aware that furnace brazing will anneal the entire assembly, which may unacceptably reduce material strength.

- If your design involves loose tolerances or wide gaps: Furnace brazing is unsuitable, as it relies on tight, consistent capillary gaps for the filler metal to flow properly.

- If you require a portable or rapid, low-volume joining solution: The batch nature and equipment of furnace brazing make methods like torch brazing or welding more practical.

- If your components have a high risk of distortion: You must commit to precise thermal cycle control, as improper heating or cooling will negate the low-stress benefits of the process.

Ultimately, furnace brazing is a powerful process for high-volume, high-precision production when you can design the part and the process around its requirements.

Summary Table:

| Disadvantage | Key Challenge | Impact on Assembly |

|---|---|---|

| Tight Joint Clearances | Requires precise capillary action for filler metal flow | Poor flow, voids, or incomplete joints if tolerances are not met |

| Annealing of Components | Entire assembly is heated, softening previously hardened materials | Loss of strength in base materials; may require post-brazing heat treatment |

| Design for Filler Placement | Parts must accommodate pre-placed braze alloy (e.g., grooves, chamfers) | Increased design complexity and potential for higher machining costs |

| Risk of Thermal Distortion | Uniform heating can still cause warping if not properly controlled | Joint misalignment or failure if components are not thermally stable |

| Process Control Demands | Precise thermal cycles (ramp-up, soak, cooling) are non-negotiable | Inconsistent results or failure if cycles deviate; not suitable for one-off repairs |

Need expert guidance on selecting the right brazing process for your lab or production needs? At KINTEK, we specialize in lab equipment and consumables, including brazing solutions tailored to your specific requirements. Whether you're dealing with tight tolerances, heat-sensitive materials, or high-volume production, our team can help you optimize your process for strong, reliable joints. Contact us today to discuss how we can support your laboratory and manufacturing challenges!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the most commonly used metals in a vacuum furnace's hot zone? Discover the Key to High-Purity Processing

- At what temperature does molybdenum evaporate? Understanding Its High-Temperature Limits

- Can an arc happen in a vacuum? Yes, and here's how to prevent it in your high-voltage design.

- What happens to heat generated in a vacuum? Mastering Thermal Control for Superior Materials

- What materials are used in a vacuum furnace? A Guide to Hot Zone Materials and Processed Metals