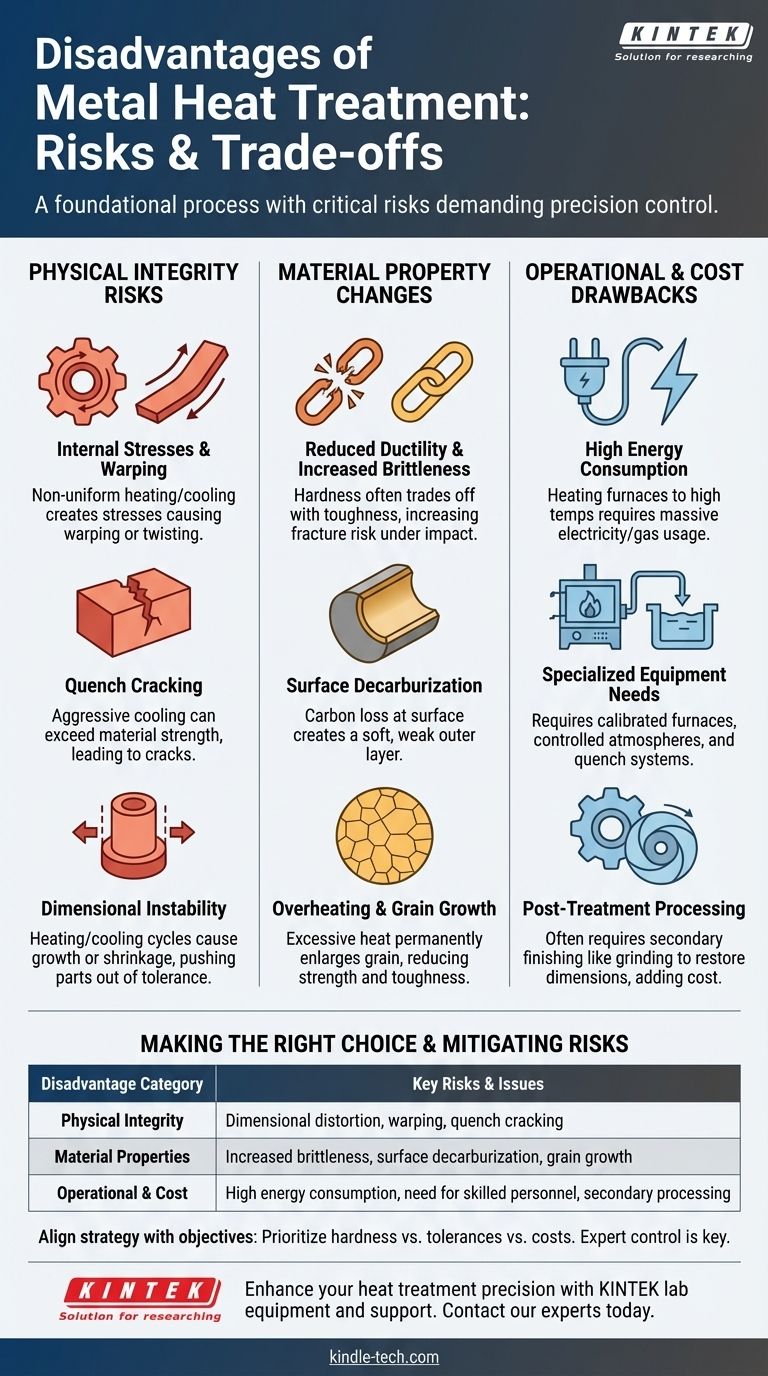

While heat treatment is a foundational process for enhancing metal properties, it is not without significant risks and drawbacks. The primary disadvantages include the potential for dimensional distortion or cracking, undesirable changes in material properties like increased brittleness, and the high operational costs associated with energy consumption and specialized equipment.

The disadvantages of heat treatment are not fundamental failures of the process itself, but rather critical risks that demand expert control. Every benefit, from increased hardness to improved strength, comes with a trade-off in other properties and introduces the potential for costly errors if not managed with precision.

The Risk of Physical Distortion and Cracking

The most immediate and visible drawbacks of heat treatment involve changes to the physical integrity of the part. The extreme temperature changes intrinsic to the process create powerful internal forces.

Internal Stresses and Warping

As a metal part is heated and cooled, different sections expand and contract at different rates. This non-uniform temperature gradient creates internal stresses that can cause the part to warp, bend, or twist out of its specified shape.

Quench Cracking

The rapid cooling (quenching) required to achieve high hardness is the most stressful phase of the process. If the cooling is too aggressive for the material's geometry or composition, the internal stresses can exceed the material's strength, leading to the formation of quench cracks.

Dimensional Instability

Even without catastrophic failure, the heating and cooling cycles will cause the part to grow or shrink. This change in dimension can easily push a precision component outside of its required engineering tolerances, necessitating costly rework or causing it to be scrapped entirely.

Unintended Changes in Material Properties

Heat treatment is a delicate balance. While the goal is to improve one property, such as hardness, it can inadvertently degrade others.

Reduced Ductility and Increased Brittleness

The core trade-off in hardening steel is hardness versus toughness. A very hard material is often very brittle, meaning it has a lower resistance to fracturing under impact. A process like tempering is required after quenching to restore some ductility, but finding the perfect balance is a significant metallurgical challenge.

Surface Decarburization

In high-temperature environments, the carbon can diffuse out of the surface of the steel, a process known as decarburization. This leaves a soft, weak outer layer on a part that was intended to be hard, defeating the purpose of the treatment and compromising wear resistance.

Overheating and Grain Growth

If a metal is heated to too high a temperature or held there for too long, its internal crystalline structure (grain) can grow excessively large. This condition, known as overheating, permanently reduces the material's strength and toughness, and it cannot be reversed by subsequent heat treatment.

Understanding the Trade-offs: Operational and Cost Drawbacks

Beyond the material risks, heat treatment introduces significant operational and financial challenges that must be factored into any manufacturing plan.

High Energy Consumption

Heating large industrial furnaces to the required temperatures (often over 800°C or 1500°F) consumes a massive amount of electricity or natural gas. This makes heat treatment an energy-intensive and expensive step in the production process.

Requirement for Specialized Equipment

Proper heat treatment requires highly controlled environments. This means investing in calibrated furnaces, quench tanks with agitated fluid, and potentially atmosphere-controlled systems to prevent oxidation and decarburization.

Need for Skilled Personnel

This is not a simple "push-button" process. It requires skilled operators and metallurgists who understand how a specific alloy will respond to a given thermal cycle. Incorrect process parameters are a primary cause of part failure.

Post-Treatment Processing

Due to the near-certainty of some dimensional change, parts that have been heat-treated often require secondary finishing operations. This can include grinding or lapping to restore final dimensions and surface finish, adding extra steps, time, and cost to production.

Making the Right Choice for Your Goal

To manage these disadvantages, you must align your heat treatment strategy with your primary engineering objective.

- If your primary focus is achieving maximum hardness for wear resistance: You must accept the risk of brittleness and plan for a carefully controlled quench followed by an immediate and precise tempering cycle.

- If your primary focus is maintaining tight dimensional tolerances: Consider slower cooling methods, stress-relieving cycles, or alternative surface-hardening processes like nitriding that operate at lower temperatures and cause less distortion.

- If your primary focus is managing production costs: Ensure the material truly requires heat treatment, optimize furnace loading to maximize energy efficiency, and implement rigorous process controls to minimize the rate of scrapped parts.

Ultimately, treating heat treatment as a precision engineering discipline—not just a heating process—is the key to unlocking its benefits while controlling its inherent risks.

Summary Table:

| Disadvantage Category | Key Risks & Issues |

|---|---|

| Physical Integrity | Dimensional distortion, warping, quench cracking |

| Material Properties | Increased brittleness, surface decarburization, grain growth |

| Operational & Cost | High energy consumption, need for skilled personnel, secondary processing |

Mitigate the risks of heat treatment in your lab.

Every heat treatment process is a balance of benefits and potential drawbacks. KINTEK specializes in providing the high-quality lab equipment and expert support you need to achieve precise thermal control and minimize distortion, cracking, and other costly errors.

Our range of furnaces and consumables are designed for reliability and repeatability, helping you optimize your processes for better material outcomes and cost-efficiency.

Ready to enhance your heat treatment precision? Contact our experts today to discuss your specific laboratory needs and discover how KINTEK can be your trusted partner in materials science.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- Why is high-precision temperature control essential in sintering Ti/Al3Ti? Achieve Defect-Free Composite Materials

- What is the heating range of a muffle furnace? From 800°C to 1800°C for Your Lab Needs

- What is the significance of sintering? Unlock Strong, Complex Parts Without Melting

- What specific technical requirements must a high-temperature box furnace meet for LSTH perovskite? Achieve 1450°C Purity

- How do high-temperature furnaces and quenching media evaluate Cr/CrxN coatings? Testing Thermal Shock Durability

- How is a high-temperature muffle furnace utilized in the solid-phase synthesis of Beta-Al2O3? Boost Ionic Conductivity

- What is the ashing method in analytical chemistry? A Key Process for Precise Sample Analysis

- Which insulator is used in muffle furnace? Choose the Right Refractory for Your Heat Needs