Ultimately, the disadvantages of nitriding stem from its specificity and slower processing time compared to the more versatile carburizing method. While nitriding excels at producing extremely hard, dimensionally stable surfaces, it is restricted to certain alloy steels, achieves a shallower case depth, and can be a more time-consuming and costly process for many common applications.

The choice between nitriding and carburizing is a classic engineering trade-off. Nitriding provides superior hardness and minimal distortion for specific materials, while carburizing offers greater case depth and flexibility for a broader range of low-carbon steels.

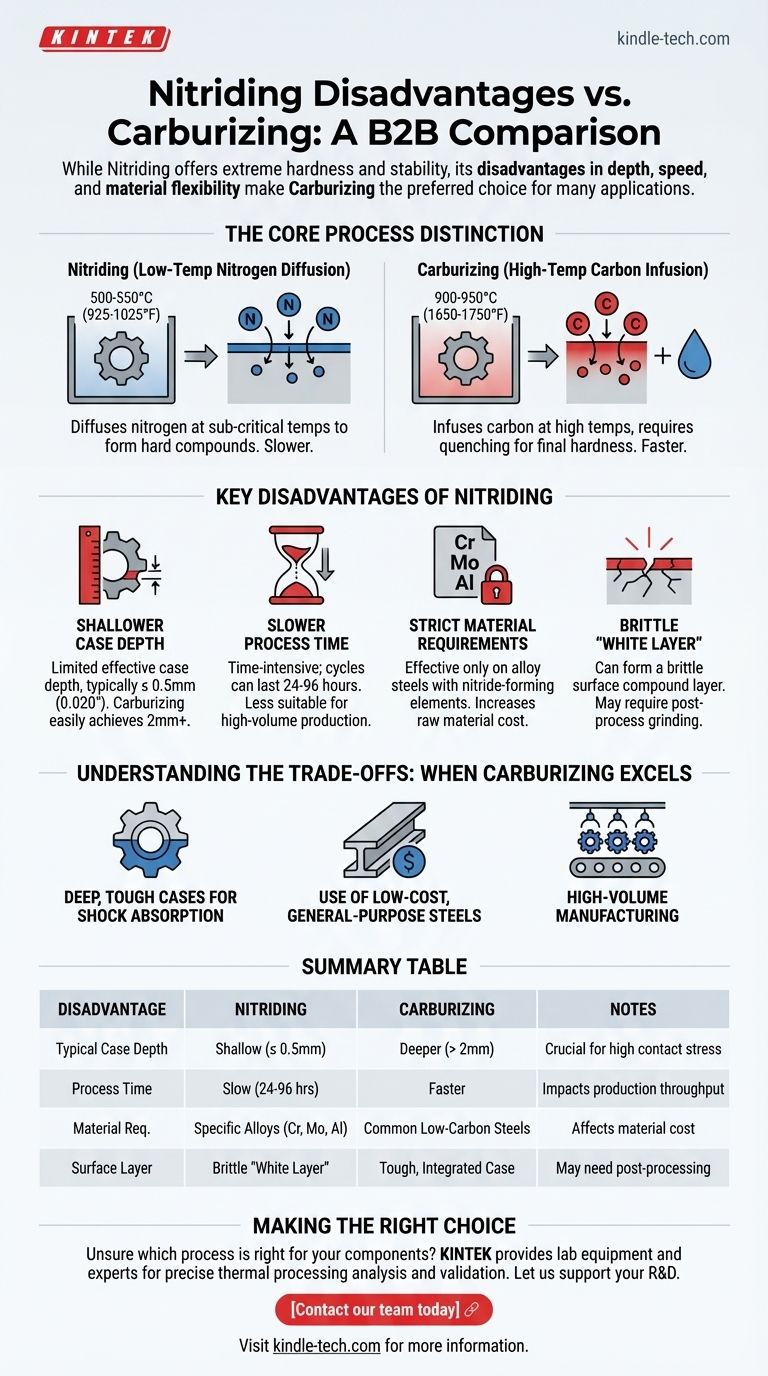

The Core Process Distinction

To understand the disadvantages, it's crucial to first recognize the fundamental difference in how these two processes work. They are not interchangeable; they achieve surface hardening through entirely different mechanisms.

Nitriding: Low-Temperature Nitrogen Diffusion

Nitriding is a diffusion process performed at sub-critical temperatures (typically 500-550°C or 925-1025°F). At this temperature, nitrogen atoms are diffused into the surface of the steel, where they react with specific alloying elements to form extremely hard nitride compounds.

Carburizing: High-Temperature Carbon Infusion

Carburizing is performed at much higher temperatures (900-950°C or 1650-1750°F). Carbon is infused into the surface of a low-carbon steel, creating a high-carbon "case." This part must then be quenched and tempered to develop its final hardness and properties.

Key Disadvantages of Nitriding

While its low-temperature nature provides benefits, it also introduces several limitations when compared directly with carburizing.

Shallower Case Depth

The most significant disadvantage is nitriding's limited effective case depth. The process is inherently slow, and achieving deep cases is often impractical, typically being limited to around 0.5mm (0.020").

Carburizing, by contrast, can easily and economically produce much deeper cases, often exceeding 2mm (0.080"), which is essential for components under high contact stress or requiring significant material removal after treatment.

Slower Process Time

Nitriding is a time-intensive process. A typical cycle can last anywhere from 24 to 96 hours to achieve even a modest case depth.

This slow diffusion rate makes it less suitable for high-volume production where rapid throughput is a primary concern. Carburizing cycles are generally much shorter for a comparable or deeper case.

Strict Material Requirements

Nitriding is only effective on steels containing nitride-forming alloy elements like chromium, molybdenum, aluminum, and vanadium. Plain low-carbon steels do not respond well to the process.

This material restriction increases the raw material cost and limits the application of nitriding. Carburizing works excellently on common, inexpensive low-carbon and alloy steels.

Potential for a Brittle "White Layer"

The nitriding process can form a thin, compound layer on the very surface known as the "white layer." While very hard, this layer can be extremely brittle and may need to be removed through grinding for applications sensitive to cracking or spalling.

Controlling the formation of this layer requires precise process control, adding complexity and potential cost.

Understanding the Trade-offs: When Carburizing Excels

The disadvantages of nitriding highlight the specific scenarios where carburizing is the more practical and effective choice.

When Deep, Tough Cases are Needed

Carburizing creates a high-carbon steel case over a soft, ductile low-carbon core. After quenching, this results in a component with a hard, wear-resistant surface and a tough core capable of absorbing shock loads without fracturing.

For Low-Cost, General-Purpose Steels

The ability to use inexpensive plain low-carbon steels is a major advantage of carburizing. It allows engineers to design cost-effective parts that still meet demanding surface hardness requirements.

For High-Volume Manufacturing

Due to its faster cycle times for achieving significant case depths, carburizing is far better suited for the mass production of components like gears, shafts, and bearings.

Making the Right Choice for Your Application

Selecting the correct case-hardening process requires a clear understanding of your component's material, its intended function, and your production goals.

- If your primary focus is dimensional stability and extreme surface hardness on an alloy steel: Nitriding's low-temperature process minimizes distortion, making it ideal for finished parts with tight tolerances.

- If your primary focus is achieving a deep, impact-resistant case on a low-cost steel: Carburizing is the definitive, industry-standard choice for its versatility and cost-effectiveness.

- If your primary focus is fatigue resistance and wear in a non-corrosive environment: Nitriding provides excellent wear and fatigue properties, but the material must be selected specifically for the process.

Choosing the right surface treatment is a critical design decision based on balancing performance requirements with material and processing costs.

Summary Table:

| Disadvantage | Nitriding | Carburizing |

|---|---|---|

| Typical Case Depth | Shallow (≤ 0.5mm / 0.020") | Deeper (often > 2mm / 0.080") |

| Process Time | Slow (24-96 hours) | Faster for comparable depth |

| Material Requirements | Requires specific alloy steels (e.g., with Cr, Mo, Al) | Works with common, low-cost low-carbon steels |

| Surface Layer | Can form a brittle "white layer" requiring post-process removal | Creates a tough, integrated case after quenching |

Still unsure which surface hardening process is right for your components?

Choosing between nitriding and carburizing is a critical decision that impacts your component's performance, cost, and production timeline. KINTEK specializes in providing the lab equipment and consumables necessary for precise thermal processing analysis. Our experts can help you validate your material choices and optimize your heat treatment parameters.

Let KINTEK support your R&D and quality control processes. Contact our team today to discuss your specific application needs and ensure you select the most effective and efficient surface hardening method for your laboratory's projects.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout