While valued for its unique properties, graphite is not a universally ideal material. Its primary disadvantages are its inherent brittleness, its tendency to generate contaminating dust, and its vulnerability to oxidation at moderately high temperatures in the presence of air. These limitations stem directly from its atomic structure and manufacturing process.

The core challenge with graphite is that its defining strengths—like high-temperature stability and lubricity—are intrinsically linked to its greatest weaknesses. Success requires understanding that its performance is highly dependent on its grade, manufacturing process, and operating environment.

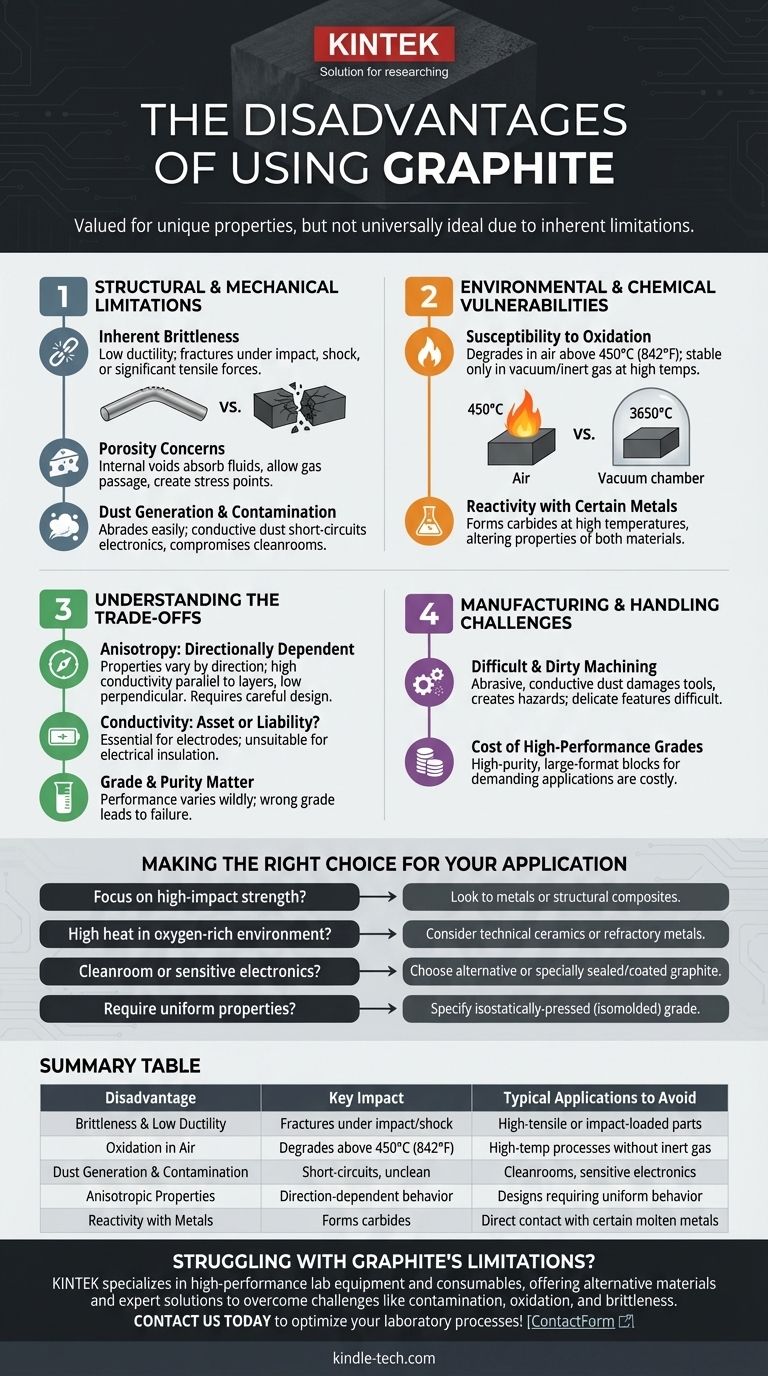

Structural and Mechanical Limitations

Graphite's performance under physical stress is fundamentally different from that of metals. Its ceramic-like nature dictates how and where it can be used effectively.

Inherent Brittleness

Graphite has very low ductility. Unlike a metal that will bend or deform under stress, graphite will fracture. This makes it unsuitable for applications involving high impact, shock loading, or significant tensile forces.

Porosity Concerns

Many common grades of graphite are porous. This internal empty space can absorb fluids, allow gases to pass through, and create stress concentration points that can initiate cracks and reduce overall strength.

Dust Generation and Contamination

Graphite is relatively soft and abrades easily, shedding fine particles. This graphite dust is electrically conductive and can be a major source of contamination, short-circuiting electronics and compromising processes in cleanroom environments.

Environmental and Chemical Vulnerabilities

While stable in many conditions, graphite has specific environmental triggers that cause it to break down, often at temperatures far below its sublimation point.

Susceptibility to Oxidation

This is one of graphite's most significant limitations. While it can withstand extreme heat in a vacuum or inert atmosphere (sublimating around 3650°C), it begins to oxidize and degrade in air at temperatures as low as 450°C (842°F).

Reactivity with Certain Metals

At high temperatures, graphite can react with certain metals, forming carbides. This can alter the properties of both the graphite and the metal component it is in contact with, which can be a problem in metallurgical and furnace applications.

Understanding the Trade-offs

The properties of graphite are rarely straightforward. What is considered an advantage in one context can be a significant drawback in another.

Anisotropy: A Double-Edged Sword

Graphite's layered atomic structure means its properties are often anisotropic, or directionally dependent. For example, thermal and electrical conductivity are much higher parallel to the layers than perpendicular to them. If a design does not account for this directionality, it can lead to unexpected hot spots or electrical behavior.

Conductivity: Asset or Liability?

Its ability to conduct electricity is essential for applications like electrodes and brushes. However, this same property makes it completely unsuitable for components that require electrical insulation.

Grade and Purity Matter

"Graphite" is a broad term. An inexpensive, extruded grade will have vastly different properties (and limitations) than a high-purity, isostatically-molded grade. Choosing the wrong grade for an application is a common source of failure.

Manufacturing and Handling Challenges

Working with graphite presents unique difficulties compared to more common engineering materials.

Difficult and Dirty Machining

Machining graphite creates an abrasive and conductive dust that can damage machine tool components and create a hazardous work environment if not properly contained. The material's brittleness also makes machining fine, delicate features very challenging.

Cost of High-Performance Grades

While simple graphite powder is inexpensive, high-purity, high-density, and large-format graphite blocks required for demanding applications can be very costly to produce.

Making the Right Choice for Your Application

Selecting the right material requires weighing these disadvantages against your primary goal.

- If your primary focus is high-impact mechanical strength: Look to metals or structural composites, as graphite's brittleness is a critical liability.

- If your application involves high heat in an oxygen-rich environment: Consider technical ceramics or refractory metals unless you can provide an inert atmosphere for the graphite.

- If you are working in a cleanroom or with sensitive electronics: Choose an alternative material or a specially sealed/coated grade of graphite to prevent particle shedding.

- If you require uniform properties in all directions: Ensure you specify an isostatically-pressed (isomolded) grade of graphite, not a less expensive extruded grade.

By understanding these limitations, you can leverage graphite's strengths where they matter most and avoid misapplication in scenarios it simply isn't designed for.

Summary Table:

| Disadvantage | Key Impact | Typical Applications to Avoid |

|---|---|---|

| Brittleness & Low Ductility | Fractures under impact/shock | High-tensile or impact-loaded parts |

| Oxidation in Air | Degrades above 450°C (842°F) | High-temp processes without inert gas |

| Dust Generation & Contamination | Short-circuits electronics, unclean | Cleanrooms, sensitive electronics |

| Anisotropic Properties | Direction-dependent conductivity/heat flow | Designs requiring uniform behavior |

| Reactivity with Metals | Forms carbides at high temperatures | Direct contact with certain molten metals |

Struggling with graphite's limitations in your lab? KINTEK specializes in high-performance lab equipment and consumables, offering alternative materials and expert solutions to overcome challenges like contamination, oxidation, and brittleness. Our team can help you select the right materials for your specific application, ensuring reliability and efficiency. Contact us today to optimize your laboratory processes!

Visual Guide

Related Products

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Continuous Graphitization Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How is synthetic graphite manufactured? A Deep Dive into the High-Temperature Process

- Can graphite withstand high-temperature? Maximizing Performance in Controlled Atmospheres

- At what temperature does graphite melt? Understanding Its Extreme Phase Change

- Why graphite has high thermal conductivity? Unlock Superior Heat Management with Its Unique Structure

- Is graphite good in high temperature? Unlocking Its Extreme Heat Potential