In the near future, Carbon Nanotubes (CNTs) are poised to move from the laboratory into mainstream applications, primarily as additives to create ultra-strong composites for aerospace and automotive parts, and to enhance the performance of next-generation batteries and supercapacitors. Their longer-term, more revolutionary uses are targeted at replacing silicon in computer chips, enabling targeted drug delivery systems in medicine, and creating materials strong enough for concepts like a space elevator.

The core potential of Carbon Nanotubes doesn't lie in a single application, but in their unique combination of extreme strength, light weight, and excellent electrical and thermal conductivity. This makes them a foundational "platform technology" capable of dramatically improving performance across dozens of independent industries.

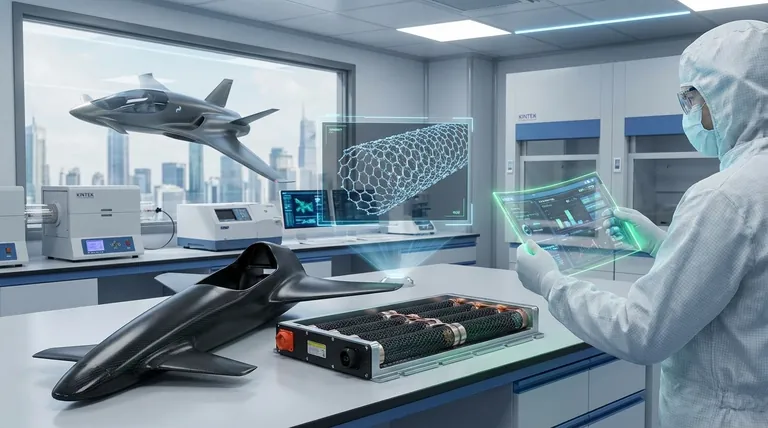

Why Carbon Nanotubes Are a Game-Changer

To understand their future uses, we must first understand the remarkable fundamental properties that set CNTs apart from conventional materials. They are, in essence, rolled-up sheets of single-layer carbon atoms (graphene).

Unprecedented Mechanical Strength

CNTs are the strongest and stiffest materials yet discovered in terms of tensile strength and elastic modulus. A single nanotube is proportionally over 100 times stronger than steel at one-sixth the weight.

Superior Electrical & Thermal Conductivity

Depending on their atomic structure, CNTs can act as either metallic conductors or semiconductors. Metallic CNTs can carry over 1,000 times the current density of copper, while semiconducting CNTs are seen as a potential successor to silicon in electronics. They also exhibit exceptional thermal conductivity, rivaling that of diamond.

Extreme Aspect Ratio

CNTs are incredibly long and thin. This high length-to-diameter ratio is critical for creating conductive networks within other materials at very low concentrations and for efficiently transferring load in composite materials.

A Revolution in Electronics and Computing

The semiconductor industry is approaching the physical limits of silicon. CNTs offer a path forward, promising smaller, faster, and more energy-efficient components.

Beyond-Silicon Transistors

Because they can be made incredibly small and conduct electricity with near-zero resistance, CNTs are a leading candidate to replace silicon in the transistors that power our computers. This could break through current performance plateaus.

Flexible and Transparent Displays

Films made from CNTs can be both electrically conductive and highly transparent. This makes them ideal for creating flexible touch screens, wearable electronics, and foldable displays that are more durable than current materials.

Advanced Sensors

The high surface area of CNTs makes them exquisitely sensitive to their environment. By attaching specific molecules to their surface, they can be used to create highly sensitive sensors for detecting minute traces of chemicals or biological markers for disease.

Transforming Energy Storage and Generation

The global push for better energy solutions is a key driver for CNT adoption. Their conductivity and high surface area are perfectly suited for improving batteries and other storage devices.

Next-Generation Batteries

When added to lithium-ion battery electrodes, CNTs create a highly conductive network that dramatically improves charge and discharge rates. This leads to batteries that can be charged faster and deliver more power.

High-Performance Supercapacitors

Supercapacitors store energy like batteries but can charge and discharge almost instantly. The massive surface area of CNTs allows them to store far more energy than traditional supercapacitors, bridging the gap between them and batteries.

Engineering the Materials of Tomorrow

The first commercial successes for CNTs have been in materials science, where even small amounts can produce significant performance gains.

Ultra-Strong, Lightweight Composites

Adding CNTs to polymers, metals, or ceramics creates composite materials that are significantly stronger, stiffer, and lighter. These are already being used in high-performance applications like aircraft components, professional bicycle frames, and wind turbine blades.

Conductive Coatings and Fibers

CNTs can be used to make plastics and paints conductive. This is crucial for applications like electrostatic painting in the automotive industry, electromagnetic interference (EMI) shielding for electronics, and creating anti-static packaging.

Understanding the Trade-offs and Challenges

Despite the immense promise, several significant hurdles must be overcome for widespread, high-end adoption. These challenges are the primary focus of current research.

The Cost of Production

Manufacturing high-purity, defect-free CNTs remains an expensive and energy-intensive process. Lowering the cost of production is the single most important factor for enabling their use in mass-market products.

Purity and Control

CNT synthesis often produces a mix of different types (metallic vs. semiconducting, varying diameters). For high-precision applications like computer chips, the inability to reliably separate these types is a major roadblock.

Biocompatibility and Environmental Concerns

For medical applications, the long-term effects of CNTs on the human body and the environment are not yet fully understood. Extensive research into toxicology and biodegradability is required before they can be used in drug delivery or tissue engineering.

The Path from Lab to Market

Your expectation for seeing CNT-based products should be guided by the complexity of the application and the purity required.

- If your focus is near-term impact (now to 5 years): Expect to see CNTs used as bulk additives in composites, batteries, tires, and conductive plastics where the benefits of strength and conductivity outweigh the need for perfect purity.

- If your focus is mid-term impact (5-15 years): Look for CNTs in more advanced applications like high-performance sensors, transparent conductive films for displays, and next-generation energy storage systems that justify a higher material cost.

- If your focus is the long-term vision (15+ years): The most transformative applications, such as CNT-based processors and advanced medical therapies, will require fundamental breakthroughs in manufacturing control and safety validation.

Carbon Nanotubes are a foundational material with the potential to redefine the limits of technology across nearly every major industry.

Summary Table:

| Application Area | Key Uses | Timeline |

|---|---|---|

| Electronics & Computing | Beyond-silicon transistors, flexible displays, advanced sensors | 5-15+ years |

| Energy Storage | Next-gen batteries, high-performance supercapacitors | Now-15 years |

| Materials Science | Ultra-strong composites, conductive coatings | Now-5 years |

| Medicine | Targeted drug delivery, biosensors | 15+ years |

Ready to integrate cutting-edge materials into your research or production? KINTEK specializes in providing high-quality lab equipment and consumables tailored to advanced material science and nanotechnology applications. Whether you're developing next-generation composites, energy storage solutions, or electronic components, our expertise and products can support your innovation. Contact us today to discover how we can help accelerate your projects with reliable, precision tools.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

People Also Ask

- What are the advantages of industrial CVD for solid boriding? Superior Process Control and Material Integrity

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision

- What role does Chemical Vapor Deposition (CVD) equipment play in the preparation of C/C composites? Expert Analysis

- What are the methods of producing CNT? Scalable CVD vs. High-Purity Lab Techniques

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor