To maintain the integrity and performance of carbon materials, you must store them in a dry, well-ventilated environment. The core goal is to protect them from moisture, direct sunlight, and any contact with corrosive substances like strong acids or bases.

The central challenge in storing carbon materials is not their inherent instability, but their susceptibility to environmental contamination. Proper storage is a critical procedural step to prevent the degradation of their physical structure and chemical purity, ensuring they perform as expected in their intended application.

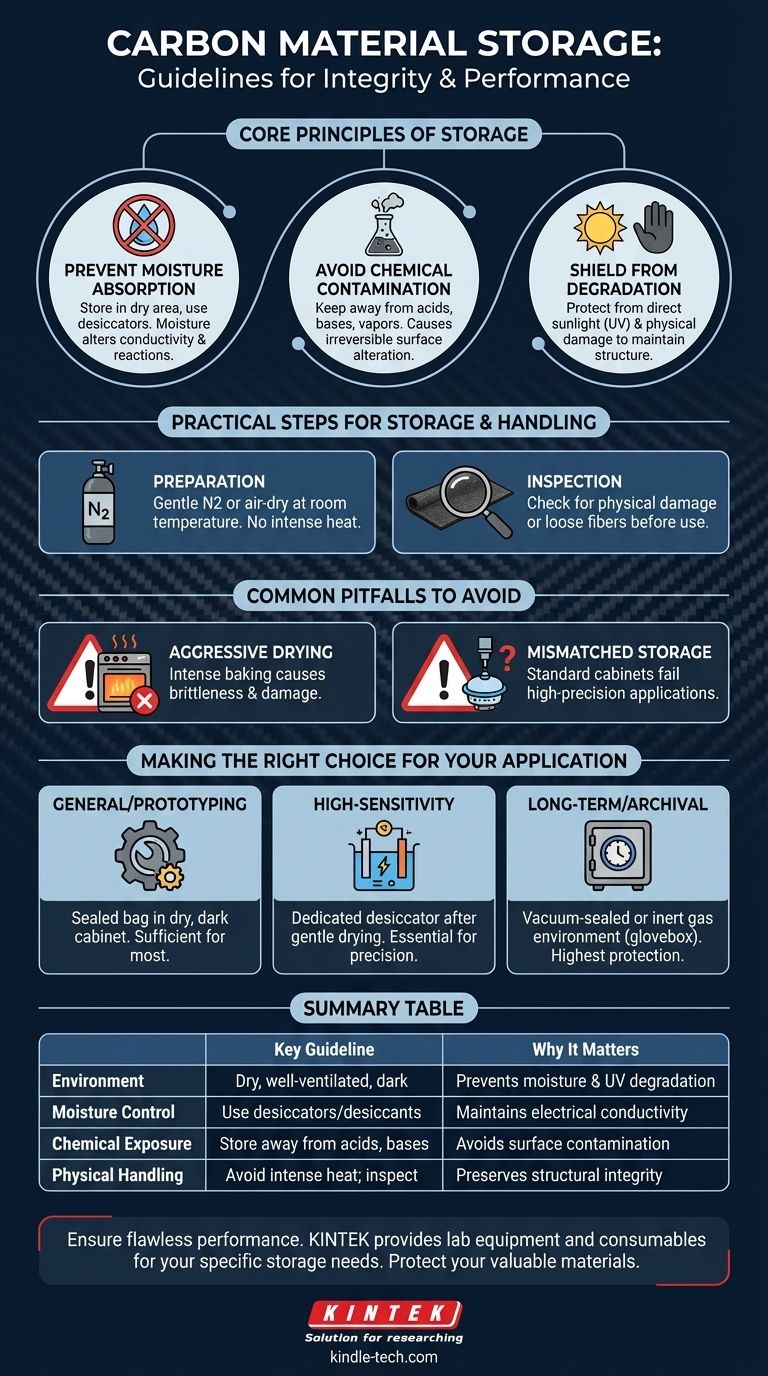

The Core Principles of Carbon Material Storage

Understanding why these guidelines exist is key to applying them correctly. Carbon materials like cloth, felt, or paper rely on their specific surface properties and structural integrity, which are easily compromised.

Preventing Moisture Absorption

Carbon materials, especially porous ones like carbon felt, can absorb moisture from the air. This moisture can interfere with electrochemical reactions, alter electrical conductivity, or block active sites crucial for catalysis.

For long-term storage or high-sensitivity applications, storing the material in a desiccator or with a desiccant is the recommended best practice.

Avoiding Chemical Contamination

The surfaces of carbon materials are reactive. Exposure to airborne chemical vapors or direct contact with corrosive substances (e.g., strong acids, strong bases) can etch the material or introduce impurities.

This chemical contamination can permanently alter the material's properties, rendering it useless for precise scientific or industrial work. Always store them far away from chemical storage areas.

Shielding from Physical Degradation

While chemically stable, the physical form of these materials is delicate. Direct sunlight (UV radiation) can degrade binders or coatings over time, leading to brittleness.

It is also crucial to handle the materials carefully to prevent tears in carbon paper or the shedding of loose fibers from carbon felt, as this affects uniformity and performance.

Practical Steps for Storage and Handling

Proper procedure extends beyond simply placing the material on a shelf. It involves preparation, inspection, and the right environment.

Preparing Materials for Storage

If a material has been used or cleaned, it must be dried correctly before storage. Use a gentle stream of nitrogen gas or allow it to air-dry at room temperature.

The goal is to remove moisture without causing thermal damage to the material's delicate structure.

The Importance of Pre-Use Inspection

Before using any stored carbon material, perform a quick inspection. Check carbon cloth or paper for any physical damage, and examine carbon felt for loose, shedding fibers.

This simple check ensures the material is still fit for its purpose and prevents compromised materials from causing experiment failure.

Common Pitfalls to Avoid

Even with the right intentions, simple mistakes can compromise your materials. Being aware of these common pitfalls is essential.

The Risk of Aggressive Drying

While materials must be dry, using intense heat is counterproductive. Avoid intense baking under an infrared lamp or in a high-temperature oven.

Excessive heat can make the carbon material brittle or damage binders within the matrix, irreversibly altering its mechanical and electrical properties.

Mismatching Storage to Application Sensitivity

A standard lab cabinet may seem sufficient, but for high-precision applications like electrochemical sensors or catalysts, it's not enough.

Even trace amounts of ambient moisture or chemical vapors can skew results. The rigor of your storage protocol must match the sensitivity of your application.

Making the Right Choice for Your Application

Your storage strategy should be dictated by the material's end-use.

- If your primary focus is general workshop or prototyping use: Storing the material in a sealed bag inside a dry, dark cabinet away from chemical fumes is often sufficient.

- If your primary focus is high-sensitivity electrochemistry or catalysis: Use a dedicated desiccator with a fresh desiccant after a controlled, gentle drying process.

- If your primary focus is long-term archival or reference standards: Storing in a vacuum-sealed container or an inert gas environment (like a glovebox) offers the highest level of protection.

Ultimately, disciplined storage is the simple, low-cost insurance that guarantees your carbon materials will deliver reliable and repeatable results.

Summary Table:

| Storage Factor | Key Guideline | Why It Matters |

|---|---|---|

| Environment | Dry, well-ventilated, dark | Prevents moisture absorption and UV degradation |

| Moisture Control | Use desiccators or desiccants | Maintains electrical conductivity and catalytic activity |

| Chemical Exposure | Store away from acids, bases, vapors | Avoids surface contamination and property alteration |

| Physical Handling | Avoid intense heat; inspect before use | Preserves structural integrity and material uniformity |

Ensure your carbon materials perform flawlessly in every application. Proper storage is key to maintaining their integrity, whether for general use or high-sensitivity electrochemistry. At KINTEK, we specialize in providing the right lab equipment and consumables—from desiccators to inert gas systems—to meet your specific storage needs.

Contact our experts today to find the perfect storage solution for your laboratory and protect your valuable materials.

Visual Guide

Related Products

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Conductive Carbon Fiber Brush for Static Removal and Cleaning

- Advanced Engineering Fine Ceramics Low Temperature Alumina Granulation Powder

- XRF Boric Acid Lab Powder Pellet Pressing Mold for Laboratory Use

People Also Ask

- What are the functions of a glassy carbon electrode in CV testing of antioxidants? Enhance Your Redox Analysis Accuracy

- What is an RVC glassy carbon sheet? A High-Performance Material for Demanding Applications

- What actions and conditions are strictly prohibited when working with a glassy carbon sheet? Protect Your Investment and Data Integrity

- What is the applicable potential range for an RVC glassy carbon sheet? Master Your Electrochemical Analysis

- What is the proper procedure for cleaning a glassy carbon sheet after use? A Definitive Guide to Ensure Reliable Results