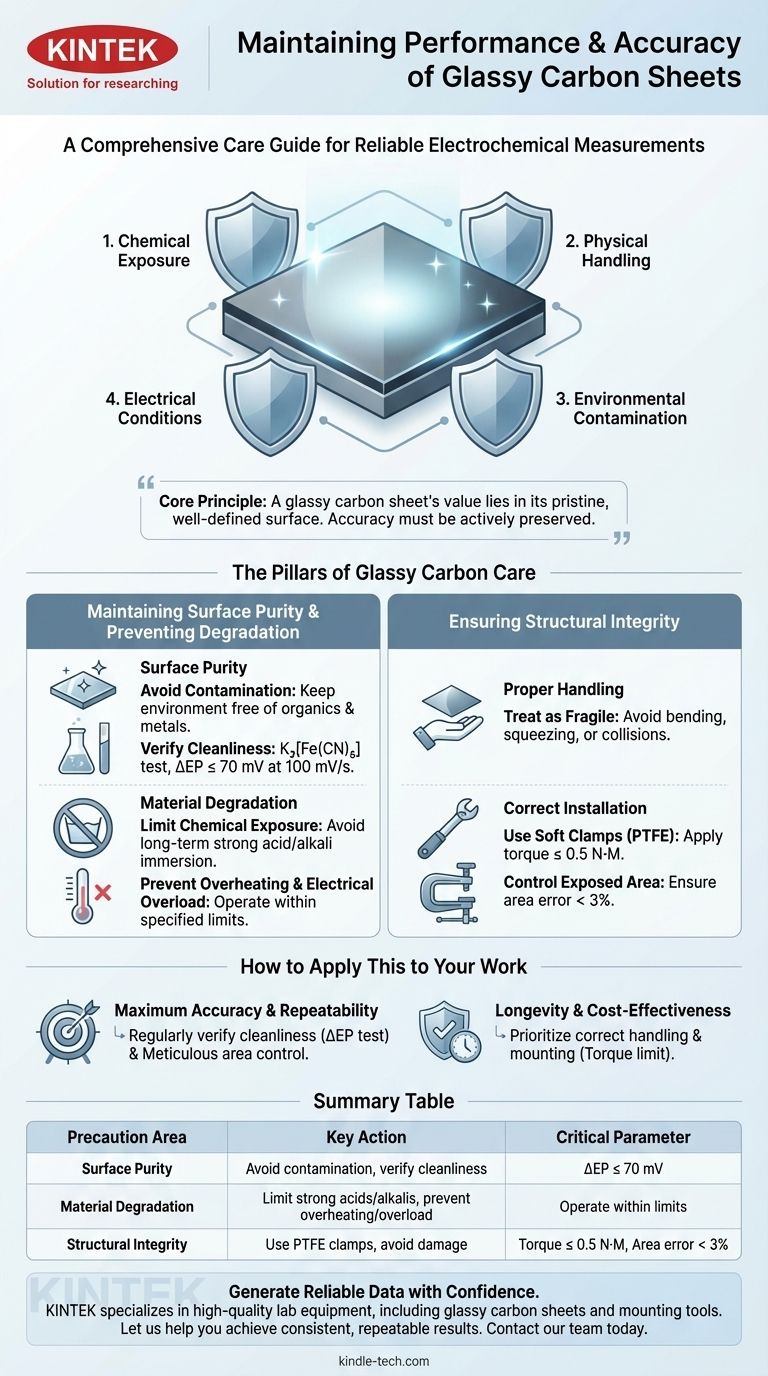

To maintain the performance and accuracy of a glassy carbon sheet, you must rigorously control four key areas: chemical exposure, physical handling, environmental contamination, and electrical operating conditions. This involves avoiding harsh chemicals and high temperatures, using precise mounting techniques, maintaining a clean environment, and operating within specified electrical limits.

The core principle is that a glassy carbon sheet's value lies in its pristine, well-defined surface. Its accuracy is not a default state but a condition that must be actively preserved through careful handling and a controlled experimental environment.

The Pillars of Glassy Carbon Care

The longevity and reliability of your glassy carbon sheet depend on a systematic approach to its use and maintenance. Each precaution is designed to protect either its surface chemistry or its physical structure, both of which are critical for accurate electrochemical measurements.

Maintaining Surface Purity

A clean, unmodified surface is essential for predictable electron transfer kinetics.

Avoid Contamination Organic substances and metal compounds can adsorb onto the electrode surface, blocking active sites and interfering with your measurements. Always maintain a clean experimental environment.

Verify Cleanliness You can quantitatively check the surface cleanliness using a potassium ferricyanide test. In a 1M K₃[Fe(CN)₆] solution, a clean electrode should exhibit a peak potential separation (ΔEP) of ≤ 70 mV in its cyclic voltammogram at a scan rate of 100 mV/s.

Preventing Material Degradation

Glassy carbon is robust but not indestructible. Chemical, thermal, and electrical extremes can cause irreversible damage.

Limit Chemical Exposure Do not immerse the sheet in strong acid or strong alkali solutions for extended periods. Prolonged exposure can etch or alter the carbon surface, permanently changing its electrochemical properties.

Prevent Overheating Avoid all contact with high-temperature sources. Excessive heat can degrade the material and compromise its structural integrity.

Operate Within Electrical Limits Always operate within the manufacturer's specified current and voltage limits. Exceeding these parameters can cause irreversible damage to the electrode surface and structure.

Ensuring Structural Integrity

The physical handling of the sheet is just as important as managing its chemical environment. Glassy carbon is brittle and susceptible to cracking if mishandled.

Proper Handling Techniques

Treat the sheet as a fragile instrument. Avoid any excessive bending, squeezing, or collisions during handling, operation, and storage to prevent catastrophic failure.

Correct Installation and Mounting

Improper mounting is a primary cause of damage and inaccurate results.

Use Appropriate Clamps and Torque When installing the sheet, use a soft clamp material like PTFE (polytetrafluoroethylene). Apply a torque of no more than 0.5 N·M to prevent the sheet from cracking under pressure.

Control the Exposed Area The accuracy of your results depends on knowing the precise electrode area. Ensure the exposed surface area is controlled with an error of less than 3%.

How to Apply This to Your Work

Your specific protocol should be guided by your primary experimental goal.

- If your primary focus is maximum accuracy and repeatability: Regularly verify surface cleanliness with the potassium ferricyanide test and be meticulous about controlling the exposed electrode area.

- If your primary focus is longevity and cost-effectiveness: Prioritize correct handling and mounting procedures, especially adhering to the specified torque limit, to prevent physical damage.

Ultimately, consistent and diligent care is the foundation for generating reliable data with your glassy carbon sheet.

Summary Table:

| Precaution Area | Key Action | Critical Parameter |

|---|---|---|

| Surface Purity | Avoid organic/metal contamination; verify cleanliness | Peak separation (ΔEP) ≤ 70 mV in K₃[Fe(CN)₆] test |

| Material Degradation | Limit exposure to strong acids/alkalis; prevent overheating | Operate within manufacturer's current/voltage limits |

| Structural Integrity | Use soft PTFE clamps; avoid bending/collisions | Mounting torque ≤ 0.5 N·M; exposed area error < 3% |

Generate Reliable Data with Confidence

Maximizing the performance and lifespan of your glassy carbon electrodes is crucial for accurate electrochemical measurements. At KINTEK, we specialize in providing high-quality lab equipment and consumables, including durable glassy carbon sheets and the precise mounting tools you need. Our experts understand the critical balance between surface purity, structural integrity, and operational limits.

Let us help you achieve consistent, repeatable results.

Contact our team today to discuss your specific application needs and ensure your lab is equipped for success.

Visual Guide

Related Products

- Glassy Carbon Electrochemical Electrode

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Graphite Disc Rod and Sheet Electrode Electrochemical Graphite Electrode

- Electrode Polishing Material for Electrochemical Experiments

- Gold Disc Electrode

People Also Ask

- How is a glassy carbon electrode activated before an experiment? Achieve Clean, Reproducible Electrochemical Data

- What is the proper post-treatment and storage procedure for a glassy carbon electrode? Ensure Reliable, Reproducible Results

- What are the functions of a glassy carbon electrode in CV testing of antioxidants? Enhance Your Redox Analysis Accuracy

- How should a glassy carbon electrode be stored during long periods of non-use? Ensure Peak Performance & Longevity

- Why is glassy carbon selected for mediator-assisted indirect oxidation of glycerol? The Key to Unbiased Research