Proper post-treatment for a glassy carbon electrode involves a simple, immediate cleaning and drying routine. Immediately after an experiment, rinse the electrode surface thoroughly with deionized water to remove any residual electrolyte, followed by a rinse with ethanol to displace the water and facilitate drying. Allow the electrode to air dry completely before placing it in a protected case for storage.

The goal of post-treatment is not just cleanliness, but the preservation of a pristine, electrochemically active surface. Your immediate actions after an experiment directly impact the reliability and reproducibility of your future measurements.

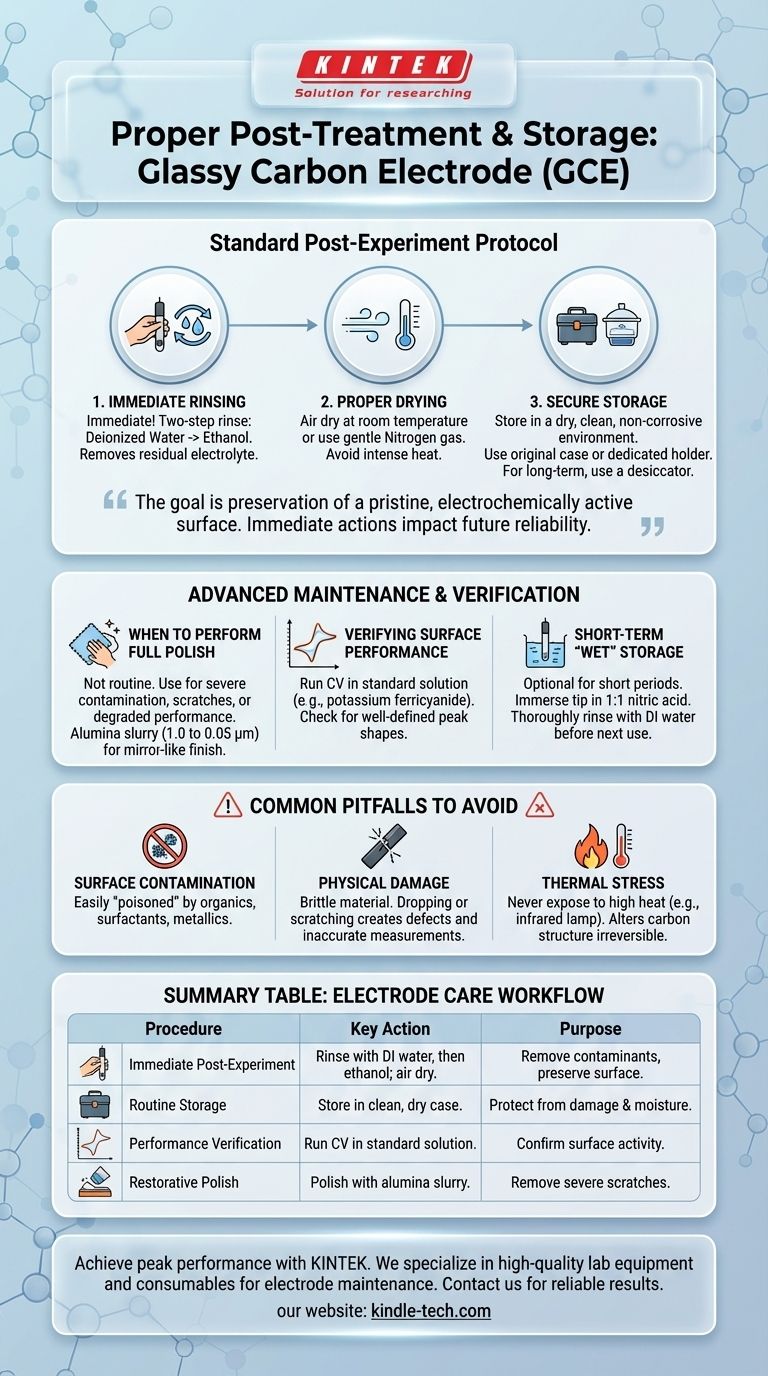

The Standard Post-Experiment Protocol

The following steps should become a standard habit after every use of a glassy carbon electrode (GCE) to ensure its longevity and performance.

Immediate Rinsing: The First Line of Defense

The most critical step is to clean the electrode immediately after removing it from the electrochemical cell.

Leaving electrolyte or reaction byproducts on the surface can lead to difficult-to-remove films or corrosion, compromising future results. A two-step rinse with deionized water followed by ethanol is the standard procedure.

Proper Drying Technique

After rinsing, the electrode must be dried completely. The best method is to allow it to air dry at room temperature.

You can also use a gentle stream of nitrogen gas. It is critical to avoid intense heat, such as baking under an infrared lamp, as high temperatures can alter the electrode's surface structure.

Secure and Dry Storage

Once clean and dry, the GCE should be stored in a dry, clean, and non-corrosive environment.

Place it back in its original protective case or a dedicated electrode holder. For long-term storage (weeks or months), keeping the electrode in a desiccator is recommended to prevent ambient moisture from adsorbing onto the surface.

Advanced Maintenance and Verification

For situations beyond routine use, more intensive procedures are required to restore or verify the electrode's performance.

When to Perform a Full Polish

Polishing is a restorative, not a routine, procedure. It is necessary when the electrode is severely contaminated, physically scratched, or when its electrochemical performance has noticeably degraded.

The process involves polishing the electrode on a polishing cloth with a slurry of alumina powder and deionized water. You should work progressively from a larger grit (e.g., 1.0 or 0.5 µm) down to a fine grit (0.05 µm) to achieve a mirror-like finish.

Verifying Surface Performance

After polishing or if you suspect a problem, you must verify the electrode's performance.

The most common method is to run cyclic voltammetry (CV) using a standard, well-behaved redox couple, such as a potassium ferricyanide solution. A properly functioning electrode will produce a voltammogram with predictable, well-defined peak shapes and separation.

Short-Term "Wet" Storage Option

For very short periods of non-use between frequent experiments, some protocols suggest immersing the electrode tip in a 1:1 nitric acid solution.

This keeps the surface active and clean. However, the electrode must be thoroughly rinsed with deionized water before its next use to remove all traces of the acid.

Common Pitfalls to Avoid

Understanding what can go wrong is as important as knowing the correct procedure. The glassy carbon material is robust chemically but sensitive in other ways.

The Risk of Surface Contamination

The GCE surface is easily "poisoned" by organic molecules, surfactants, or metallic compounds that adsorb onto active sites. This is the primary cause of poor performance and is why immediate cleaning is so crucial.

The Danger of Physical Damage

Glassy carbon is a hard but brittle material. Dropping the electrode or scratching its surface against hard objects can create defects. These scratches lead to non-uniform current distribution and inaccurate measurements.

The Impact of Thermal Stress

Never expose the electrode to high temperatures. Overheating, either from excessive current during an experiment or improper drying, can irreversibly alter the carbon structure and degrade its electrochemical properties.

A Practical Workflow for Electrode Care

Your approach to maintenance should match your experimental context.

- After every routine experiment: Immediately rinse with DI water, then ethanol, and air dry before storing in a protected case.

- If you suspect contamination or see performance drift: Perform a full polish with alumina powder, sonicate to remove polishing residue, and verify performance with a CV check in a standard solution.

- For long-term storage (weeks or months): Ensure the electrode is perfectly clean and dry, and store it in a desiccator to prevent moisture adsorption.

Consistent care of your glassy carbon electrode is the foundation for obtaining reliable and reproducible electrochemical data.

Summary Table:

| Procedure | Key Action | Purpose |

|---|---|---|

| Immediate Post-Experiment | Rinse with DI water, then ethanol; air dry. | Remove contaminants and preserve the active surface. |

| Routine Storage | Store in a clean, dry protective case. | Protect from physical damage and environmental moisture. |

| Performance Verification | Run CV in a standard solution (e.g., potassium ferricyanide). | Confirm electrode surface is electrochemically active. |

| Restorative Polish | Polish with alumina slurry (1.0 to 0.05 µm grit). | Remove severe contamination or scratches. |

Achieve peak performance and longevity for your lab's electrodes with KINTEK.

Proper electrode care is fundamental to accurate and reproducible electrochemical data. KINTEK specializes in high-quality lab equipment and consumables, including the polishing materials and storage solutions you need to maintain your glassy carbon electrodes effectively.

Let our expertise support your research. Contact our team today to discuss your laboratory needs and ensure your equipment delivers reliable results, experiment after experiment.

Visual Guide

Related Products

- Glassy Carbon Electrochemical Electrode

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Gold Disc Electrode

- Reference Electrode Calomel Silver Chloride Mercury Sulfate for Laboratory Use

People Also Ask

- What are the functions of a glassy carbon electrode in CV testing of antioxidants? Enhance Your Redox Analysis Accuracy

- Why is glassy carbon selected for mediator-assisted indirect oxidation of glycerol? The Key to Unbiased Research

- How to make a glassy carbon electrode? A Guide to the Industrial Pyrolysis Process

- What is the typical working electrode potential range for a glassy carbon electrode in aqueous electrolytes? A Guide to Accurate Electrochemical Measurements

- What are the pre-treatment steps for a glassy carbon electrode before use? Ensure Reliable Electrochemical Data