The standard method for activating a glassy carbon electrode (GCE) involves an electrochemical cleaning procedure. This is achieved by performing repeated cyclic voltammetry scans in a 0.5 M sulfuric acid (H₂SO₄) solution, cycling the potential between approximately -0.5 V and +1.5 V at a scan rate of 50 mV/s until the voltammogram stabilizes.

The goal of activation is not merely to follow a recipe, but to create a clean, electrochemically active, and reproducible electrode surface. This process removes contaminants and surface oxides that otherwise hinder electron transfer and compromise the quality and reliability of your experimental data.

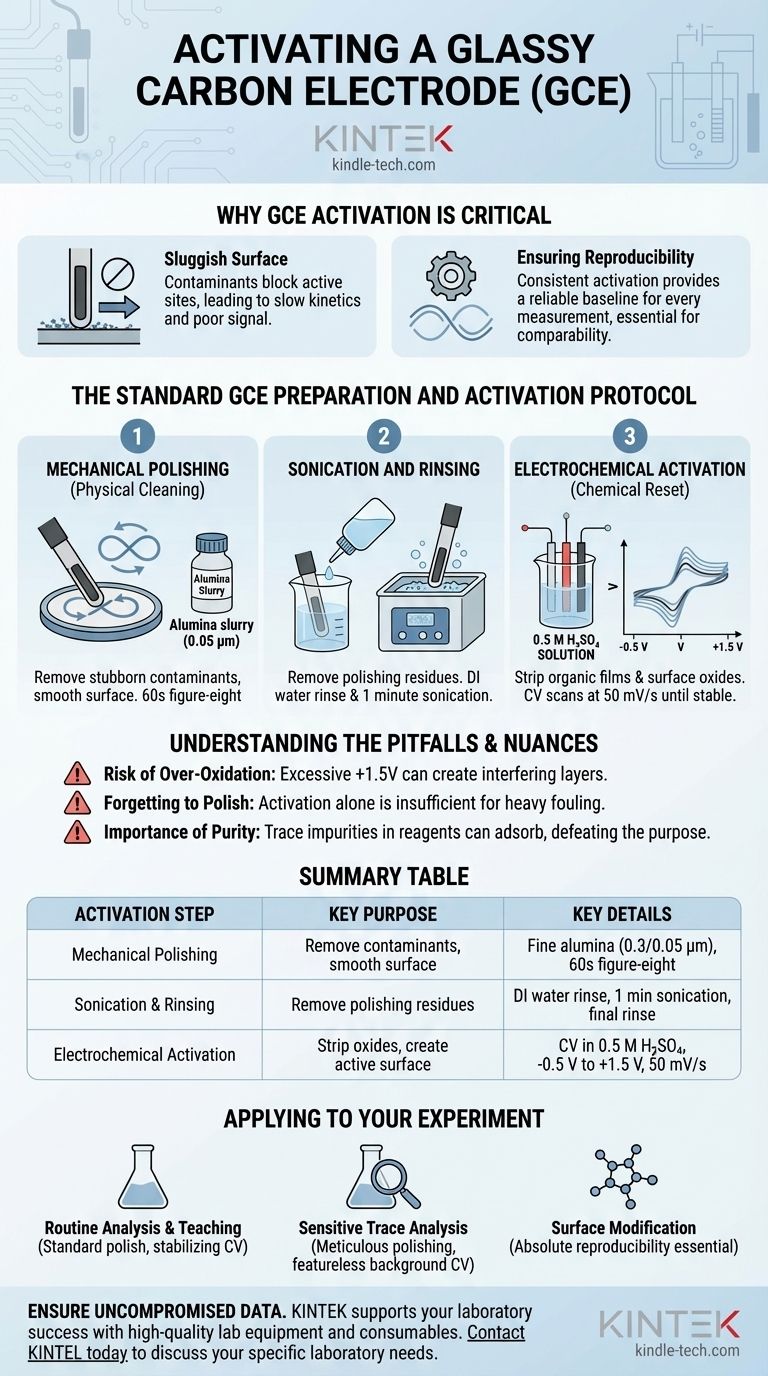

Why GCE Activation is a Critical First Step

A glassy carbon electrode, as manufactured or after previous use, is never truly clean from an electrochemical perspective. Its surface is inevitably covered with adsorbed impurities, organic residues, and a thin oxide layer.

The Problem of a "Sluggish" Surface

These contaminants block the active sites on the electrode where electron transfer occurs. This leads to "sluggish" or slow kinetics, which manifests in your data as broad, poorly defined peaks and reduced signal intensity. Proper activation removes this barrier, enabling fast and efficient electron transfer.

Ensuring Reproducibility

Without a consistent activation protocol, the initial state of your electrode will vary between experiments. This introduces a significant source of error, making it impossible to compare results or trust your findings. Activation provides a reliable, reproducible baseline for every measurement.

The Standard GCE Preparation and Activation Protocol

A complete GCE preparation involves both a physical and an electrochemical cleaning step. Following these steps ensures the best possible performance.

Step 1: Mechanical Polishing (Physical Cleaning)

Before any electrochemical treatment, the electrode must be polished. This physically removes stubborn contaminants and smooths the surface.

Gently polish the electrode surface on a polishing pad with a fine alumina slurry (e.g., 0.3 or 0.05 micron). Move the electrode in a figure-eight pattern for about 60 seconds.

Step 2: Sonication and Rinsing

After polishing, microscopic alumina particles will remain on the electrode surface. These must be removed.

Rinse the electrode thoroughly with high-purity deionized water. Then, sonicate the electrode in a beaker of deionized water for about one minute to dislodge any remaining polishing abrasive. Rinse it one final time.

Step 3: Electrochemical Activation (Chemical Reset)

This final step uses an applied potential to strip away any remaining organic films and surface oxides.

Place the polished and rinsed GCE into an electrochemical cell containing a 0.5 M H₂SO₄ solution. Run cyclic voltammetry scans, sweeping the potential between -0.5 V and +1.5 V at 50 mV/s. Continue scanning until the successive voltammograms perfectly overlap, indicating the surface has reached a stable state.

Understanding the Pitfalls and Nuances

While the protocol is straightforward, awareness of potential issues is crucial for achieving consistent results and avoiding electrode damage.

The Risk of Over-Oxidation

The positive potential limit of +1.5 V is strongly oxidizing. While this helps clean the surface, it can also create a new, thicker layer of carbon-oxygen functional groups. For some applications this is desirable, but for others, it may interfere with the reaction you intend to study. Be consistent with your potential window.

Forgetting to Polish

Skipping the mechanical polishing step is a common mistake. Electrochemical activation alone is often insufficient to remove heavy fouling from previous experiments. The polishing step creates a fresh surface for the activation to work on.

The Importance of Purity

The references rightly emphasize using high-purity reagents and water. If your sulfuric acid or water contains trace impurities (like metal ions or chlorides), they will simply adsorb onto your freshly cleaned electrode during the activation process, defeating the purpose of the procedure.

Applying This to Your Experiment

The rigor of your activation protocol can be tailored to the demands of your specific electrochemical measurement.

- If your primary focus is routine analysis or teaching: A standard polish followed by several stabilizing CV scans is an excellent and sufficient practice.

- If your primary focus is sensitive trace analysis: Meticulous polishing, thorough rinsing, and ensuring the background CV is perfectly stable and featureless are paramount for achieving a low detection limit.

- If your primary focus is studying surface modification: The activated GCE is your starting substrate, so absolute reproducibility of the activation protocol is non-negotiable to ensure your modification is consistent every time.

Ultimately, treating electrode activation as a critical, non-negotiable step is the foundation for acquiring reliable and publishable electrochemical data.

Summary Table:

| Activation Step | Key Purpose | Key Details |

|---|---|---|

| Mechanical Polishing | Remove stubborn contaminants, smooth surface. | Use fine alumina slurry (0.3/0.05 µm), figure-eight motion for 60s. |

| Sonication & Rinsing | Remove polishing abrasive residues. | Rinse with DI water, sonicate for 1 minute, final rinse. |

| Electrochemical Activation | Strip organic films & surface oxides, create active surface. | CV scans in 0.5 M H₂SO₄, -0.5 V to +1.5 V, 50 mV/s until stable. |

Ensure Your Electrochemical Data is Uncompromised

A properly activated glassy carbon electrode is the foundation of reliable and reproducible electrochemistry. KINTEK specializes in providing the high-quality lab equipment and consumables—from precision electrodes to ultra-pure reagents—that your research demands.

Let us support your laboratory's success. Our expertise ensures you have the right tools for meticulous surface preparation and accurate measurements.

Contact KINTEL today to discuss your specific laboratory needs and elevate the quality of your electrochemical data.

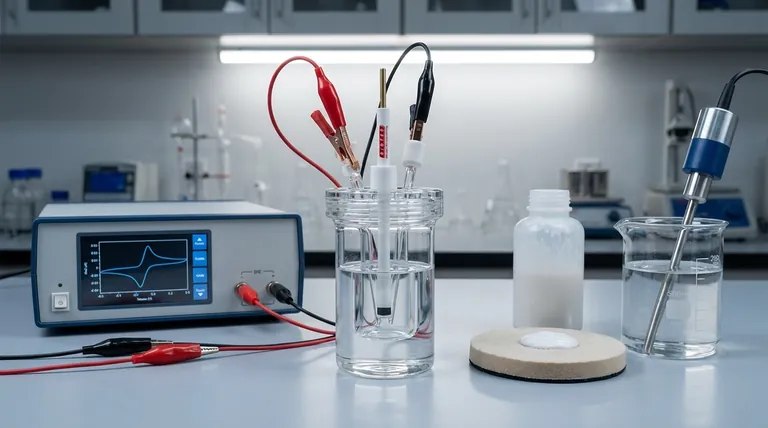

Visual Guide

Related Products

- Glassy Carbon Electrochemical Electrode

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Gold Disc Electrode

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Metal Disc Electrode Electrochemical Electrode

People Also Ask

- What are the functions of a glassy carbon electrode in CV testing of antioxidants? Enhance Your Redox Analysis Accuracy

- How should a glassy carbon electrode be stored during long periods of non-use? Ensure Peak Performance & Longevity

- How to make a glassy carbon electrode? A Guide to the Industrial Pyrolysis Process

- What is the typical working electrode potential range for a glassy carbon electrode in aqueous electrolytes? A Guide to Accurate Electrochemical Measurements

- Why is glassy carbon selected for mediator-assisted indirect oxidation of glycerol? The Key to Unbiased Research