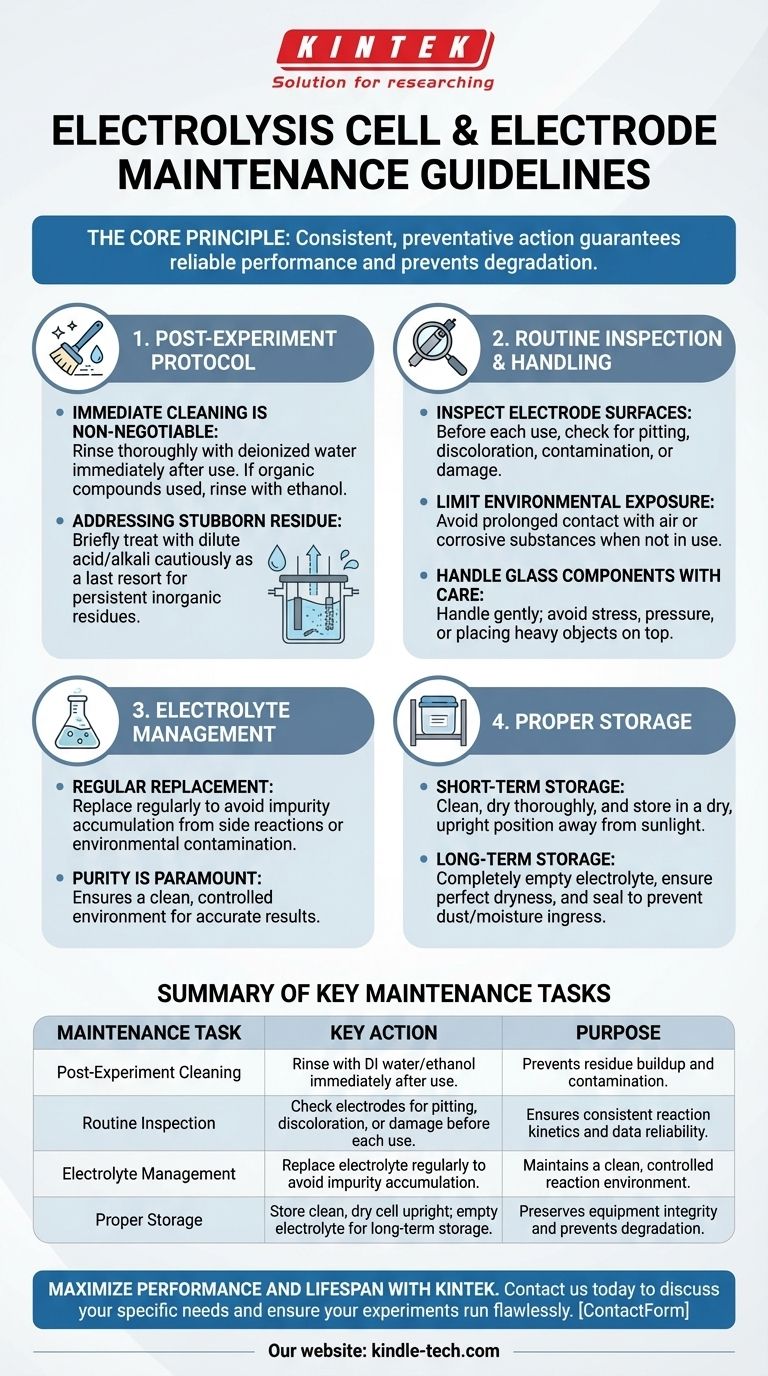

The key to maintaining your electrolysis cell is a disciplined routine of immediate post-experiment cleaning, regular inspection, and proper storage. This preventative approach is critical for preventing residue buildup and electrode contamination, which directly ensures the accuracy of your results and the longevity of the equipment.

The core principle of electrolysis cell care is not complex intervention, but consistent, preventative action. Proper maintenance immediately after each use is the single most effective way to guarantee reliable performance and avoid equipment degradation over time.

The Post-Experiment Protocol: Your First Line of Defense

What you do in the moments after an experiment concludes has the greatest impact on the cell's future performance. This immediate action prevents chemical residues from drying and bonding to sensitive surfaces.

Immediate Cleaning is Non-Negotiable

You must clean the reaction vessel and electrodes immediately after every single use. This prevents the crystallization or passivation of surfaces by residual reactants or products.

For most applications, a thorough rinse with deionized water is sufficient. If organic compounds were used, rinsing with ethanol is the next step.

Addressing Stubborn Residue

If a simple rinse is ineffective, a more targeted cleaning may be required. A brief treatment with a dilute acid or alkali solution can dissolve more persistent inorganic residues, but this should be done cautiously and as a last resort.

Routine Inspection and Handling

Physical integrity is just as important as chemical cleanliness. Regular visual checks and careful handling can prevent catastrophic failures and subtle experimental errors.

Inspecting Electrode Surfaces

Before each experiment, visually inspect the surfaces of your electrodes. Look for any signs of pitting, discoloration, contamination, or physical damage.

A compromised electrode surface can alter reaction kinetics, leading to inconsistent and unreliable data.

Limiting Environmental Exposure

Do not leave electrodes in prolonged contact with air, water, or other potentially corrosive substances when not in use. This exposure can lead to oxidation or degradation of the electrode material, permanently altering its electrochemical properties.

Handle Glass Components with Care

The glass components of the cell are fragile. Always handle the apparatus gently, ensuring you do not apply stress or pressure. Never place heavy objects on top of the cell.

Managing Your Electrolyte for Consistent Results

The electrolyte is not just a medium; it's an active component of your system. Its purity is paramount for achieving repeatable outcomes.

The Need for Regular Replacement

Over time and with use, the electrolyte can accumulate impurities from side reactions or environmental contamination. These impurities can interfere with your primary reaction.

The frequency of replacement depends on your experimental sensitivity and usage. As a rule, replace the electrolyte regularly to ensure a clean, controlled environment for your experiments.

Proper Storage: Preserving Equipment Integrity

How you store your electrolysis cell between uses determines its long-term viability. The primary goals are to keep it clean, dry, and physically safe.

Short-Term Storage

For storage between frequent experiments, ensure the cell is thoroughly dried after cleaning. Store it in a dry, upright position, away from direct sunlight and potential physical disturbances.

Long-Term Storage

If the cell will be unused for an extended period, take extra precautions. Completely empty the electrolyte from the vessel.

After ensuring the cell is perfectly dry, seal it to prevent dust and moisture from entering. This preserves the internal surfaces in a ready-to-use state.

A Practical Maintenance Checklist

Your specific maintenance focus will shift depending on your usage patterns and experimental goals.

- If your primary focus is daily use: Your most critical task is the immediate clean-and-dry protocol after every single experiment to prevent cumulative buildup.

- If your primary focus is data accuracy: Prioritize regular electrode inspection and a strict schedule for electrolyte replacement to eliminate variables.

- If your primary focus is long-term preservation: Adhere strictly to the long-term storage guidelines by emptying the electrolyte and sealing the clean, dry cell.

Adopting these disciplined habits will ensure your electrolysis apparatus remains a reliable and accurate tool for your work.

Summary Table:

| Maintenance Task | Key Action | Purpose |

|---|---|---|

| Post-Experiment Cleaning | Rinse with deionized water/ethanol immediately after use. | Prevents residue buildup and contamination. |

| Routine Inspection | Check electrodes for pitting, discoloration, or damage before each use. | Ensures consistent reaction kinetics and data reliability. |

| Electrolyte Management | Replace electrolyte regularly to avoid impurity accumulation. | Maintains a clean, controlled reaction environment. |

| Proper Storage | Store clean, dry cell upright; empty electrolyte for long-term storage. | Preserves equipment integrity and prevents degradation. |

Maximize the performance and lifespan of your laboratory equipment. Proper maintenance is key to reliable data. KINTEK specializes in high-quality lab equipment and consumables, including electrolysis cells, designed for durability and precision. Let our experts help you select the right tools and establish best practices for your lab. Contact us today to discuss your specific needs and ensure your experiments run flawlessly.

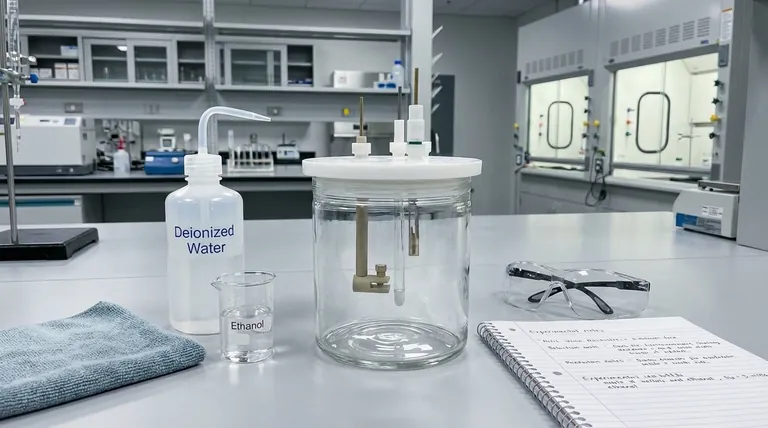

Visual Guide

Related Products

- Electrolytic Electrochemical Cell with Five-Port

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- Double-Layer Water Bath Electrolytic Electrochemical Cell

- Optical Water Bath Electrolytic Electrochemical Cell

People Also Ask

- How should the body of an electrolytic cell be maintained for longevity? Extend Your Equipment's Lifespan

- What are the proper storage procedures for the multifunctional electrolytic cell? Protect Your Investment and Ensure Data Accuracy

- What is the proper way to handle a five-port water bath electrolytic cell? Ensure Accurate and Safe Electrochemical Experiments

- How should the five-port water bath electrolytic cell be operated during an experiment? Master Precise Control for Reliable Results

- What general precaution should be taken when handling the electrolytic cell? Ensure Safe and Accurate Lab Results