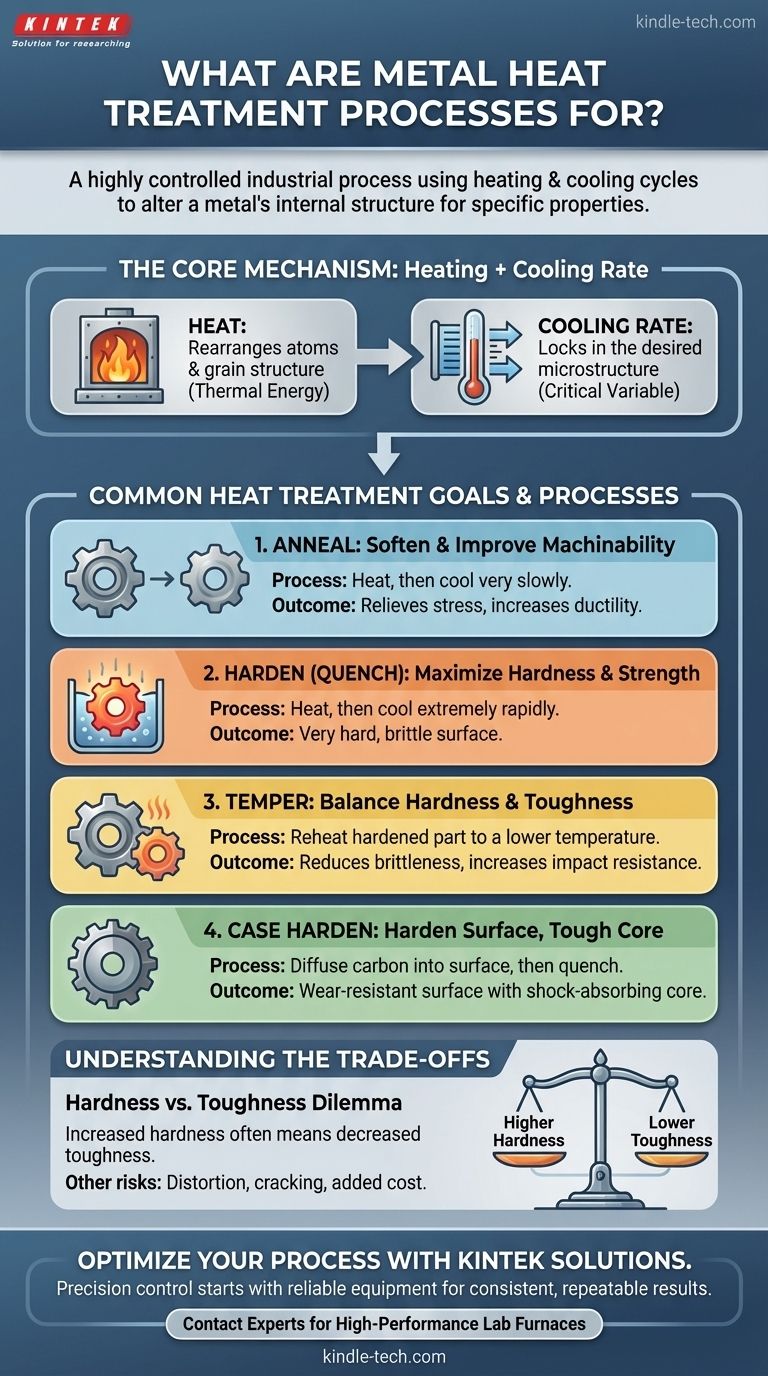

At its core, heat treatment is a highly controlled industrial process that uses specific heating and cooling cycles to intentionally alter a metal's internal structure. This is not done randomly; the sole purpose is to manipulate the metal’s physical and sometimes chemical properties to make it better suited for its intended application, such as making it harder, softer, or more durable.

The true value of heat treatment is its ability to unlock a metal's hidden potential. It allows engineers to take a standard, off-the-shelf alloy and precisely tailor its characteristics, transforming a general-purpose material into a component optimized for specific performance demands like wear resistance or impact strength.

Why a Metal's Properties Need Changing

A piece of steel for a knife blade and a piece for a car body may start from a similar alloy, but they require vastly different properties. Heat treatment is the critical step that creates this divergence in performance.

The Microstructure: A Metal's Internal Blueprint

Metals are not uniform solids. At a microscopic level, they are composed of crystalline structures called grains.

The size, shape, and composition of these grains—collectively known as the microstructure—directly dictate the metal's mechanical properties, including its hardness, toughness, and ductility (its ability to deform without breaking).

Heat as the Catalyst for Change

Heating a metal provides thermal energy to the atoms within its crystal lattice. This energy allows the atoms to move and rearrange, causing the grain structure to dissolve and reform.

By controlling the temperature and the duration of the heating, you can achieve specific structural changes.

Cooling as the Lock-In Mechanism

The rate of cooling is what locks a desired microstructure into place. This is perhaps the most critical variable in heat treatment.

Rapid cooling, known as quenching, traps the atoms in a highly stressed, distorted structure, which results in very high hardness. Slow cooling, on the other hand, allows the grains to form in a more orderly and relaxed state, resulting in a softer, more ductile metal.

Common Heat Treatment Goals and Processes

Different applications demand different properties. Heat treatment processes are named for the results they produce.

To Soften a Metal: Annealing

Annealing is the process of heating a metal and then cooling it very slowly. This process creates a uniform and fine-grained microstructure.

The primary goals are to relieve internal stresses from prior manufacturing steps, increase softness, and improve ductility. An annealed metal is much easier to machine, cut, or form.

To Maximize Hardness: Hardening (Quenching)

Hardening involves heating the metal to a specific temperature and then cooling it with extreme rapidity, often by submerging it in water, oil, or brine.

This is called quenching, and it creates a very hard but also very brittle material. A fully hardened part is strong but may shatter under a sharp impact.

To Balance Hardness and Toughness: Tempering

A quenched part is often too brittle for practical use. Tempering is a secondary process that solves this by reheating the hardened part to a lower temperature.

This reheating relieves some of the internal stress from quenching, reducing brittleness and increasing toughness. The trade-off is a slight reduction in overall hardness. The combination of quenching and tempering is extremely common for tools, springs, and structural components.

To Harden Only the Surface: Case Hardening

For parts like gears or bearings, you need a very hard, wear-resistant surface but a softer, tougher core that can absorb shock. Case hardening (or surface hardening) achieves this.

Processes like carburizing diffuse carbon into the surface of a low-carbon steel. When the part is then quenched, only the high-carbon "case" becomes extremely hard, while the low-carbon core remains tough and ductile.

Understanding the Trade-offs

Heat treatment is a powerful tool, but it is not without its challenges and compromises. Making the right choice requires understanding the inherent balances.

The Hardness vs. Toughness Dilemma

This is the most fundamental trade-off in metallurgy. As you increase a metal's hardness (its resistance to scratching and wear), you almost always decrease its toughness (its ability to absorb energy and resist fracturing).

A process like tempering is a deliberate compromise, sacrificing peak hardness to gain essential toughness and prevent catastrophic failure.

Risk of Distortion and Cracking

The rapid temperature changes involved in processes like quenching create immense internal stress within the material.

If not managed properly, this stress can cause the part to warp, distort, or even crack during or after the treatment. This risk is higher in parts with complex geometries or sharp corners.

Added Cost and Complexity

Heat treatment is an additional manufacturing step that requires specialized furnaces, quenching media, and precise process control.

This adds both time and cost to production. Therefore, it is typically reserved for components where the performance benefits justify the investment.

Making the Right Choice for Your Goal

The correct heat treatment process is determined entirely by the final application of the component.

- If your primary focus is machinability and forming: Your goal is to soften the metal and relieve stress, making annealing the correct process.

- If your primary focus is maximum wear resistance and strength: Your goal is to make the material as hard as possible, requiring a hardening process like quenching, often followed by case hardening.

- If your primary focus is durability against impact and shock: Your goal is a balance of properties, making the quench-and-temper combination essential to achieve both hardness and toughness.

By understanding these fundamental processes, you can specify not just a material, but the precise performance you require from it.

Summary Table:

| Goal | Primary Process | Key Outcome |

|---|---|---|

| Soften & Improve Machinability | Annealing | Relieves stress, increases ductility |

| Maximize Hardness & Strength | Hardening (Quenching) | Creates a very hard, wear-resistant surface |

| Balance Hardness & Toughness | Tempering (after Quenching) | Reduces brittleness, increases impact resistance |

| Harden Surface, Tough Core | Case Hardening (e.g., Carburizing) | Wear-resistant surface with a shock-absorbing core |

Ready to unlock the full potential of your materials? The precise control required for successful heat treatment starts with reliable equipment. KINTEK specializes in high-performance lab furnaces and thermal processing solutions for metallurgy, research, and production. Whether you are annealing, hardening, or tempering, our equipment ensures consistent, repeatable results.

Let's optimize your process. Contact our experts today to discuss your specific application and discover the right thermal solution for your laboratory or facility.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the operating temperature of a batch type furnace? From 200°C to 3000°C for Your Specific Process

- What are the effects of sintering? Transform Powder into Dense, Strong Components

- What is the purpose of vacuum hardening? Achieve Flawless, High-Strength Metal Components

- What are vacuum furnaces used for? Unlock Ultimate Material Purity and Performance

- Why is a vacuum oven used at 80°C to dry MOF precursors? Preserving Structural Integrity in Al-Based Materials

- How does the isothermal holding function of high-temperature furnaces affect TLP bonding joints? Achieve Seamless Bonds

- Can hydrogen be produced from biomass? A Guide to Sustainable, Low-Carbon Hydrogen

- What is vacuum carburizing? Achieve Superior Hardening with Precision & Speed