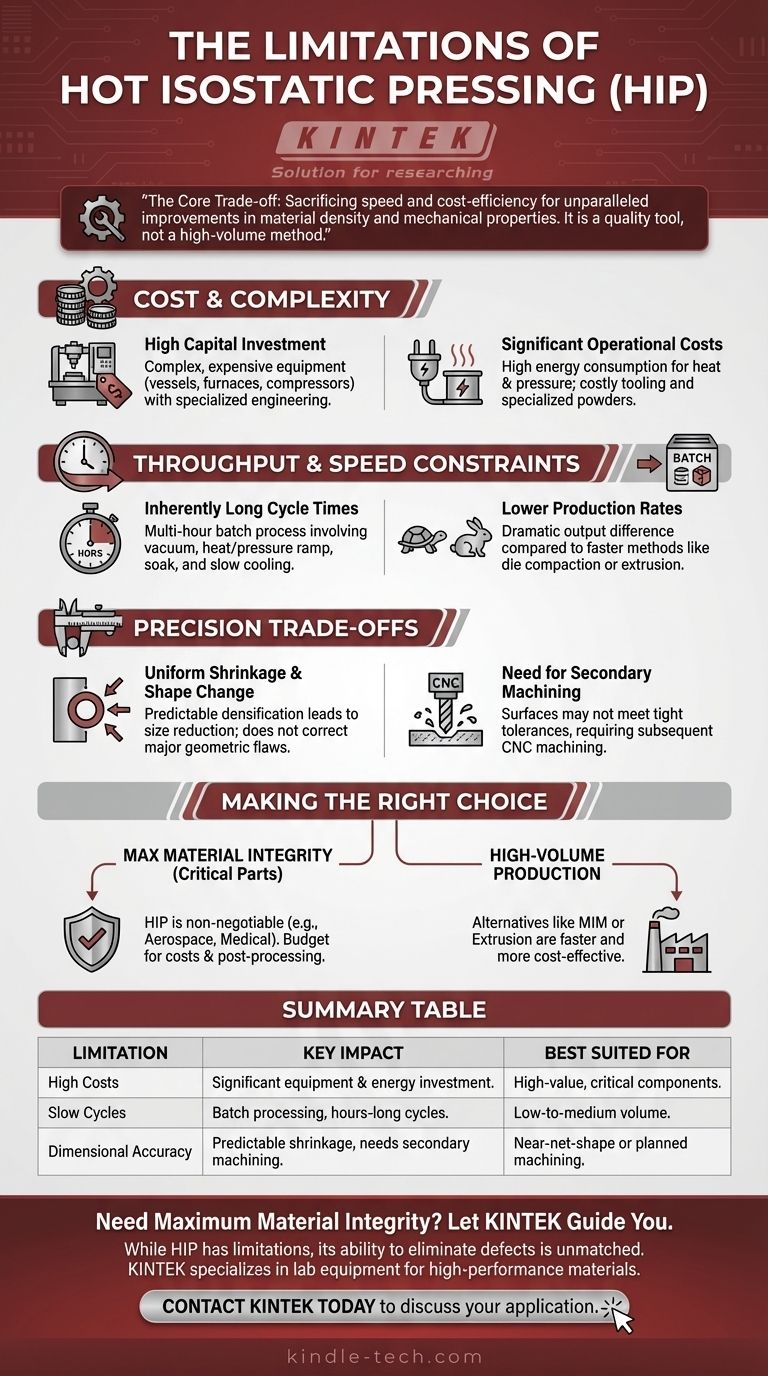

While Hot Isostatic Pressing (HIP) is an exceptionally powerful process, its primary limitations are high operational costs, slow production cycles, and challenges in achieving precise final dimensions without secondary processing. These factors make it a specialized solution best suited for high-value components rather than mass production.

The core trade-off with Hot Isostatic Pressing is clear: you are sacrificing production speed and cost-efficiency to achieve unparalleled improvements in material density and mechanical properties. It is fundamentally a quality and performance enhancement tool, not a high-volume manufacturing method.

The Core Challenge: Cost and Complexity

The significant performance benefits of HIP come at a steep price, both in initial investment and ongoing operations. This is the most common barrier to its adoption.

High Capital Investment

The equipment required for HIP is complex and expensive. A complete system includes a high-pressure vessel, an internal high-temperature furnace, powerful compressors, and sophisticated control systems.

This machinery must safely handle extreme pressures and temperatures simultaneously, demanding specialized engineering and materials that drive up the initial purchase and installation costs.

Significant Operational Costs

Beyond the initial investment, day-to-day operations are costly. The process consumes large amounts of energy to heat the furnace and run the compressors.

Furthermore, tooling can be expensive, and certain applications—particularly those forming parts from powder—may require specialized and costly spray-dried powders to ensure consistent results.

Throughput and Production Speed Constraints

HIP is an inherently slow, batch-based process. This deliberate pace is necessary for its effectiveness but limits its application for high-volume manufacturing.

Inherently Long Cycle Times

A typical HIP cycle involves loading the chamber, pulling a vacuum, backfilling with inert gas, ramping up temperature and pressure, holding at a specific "soak" time, and finally, a slow cooling and depressurization phase.

This entire sequence can take several hours, making the throughput per machine very low compared to other manufacturing methods.

Lower Production Rates vs. Alternatives

When compared to processes like uniaxial die compaction or extrusion, HIP has a dramatically lower production rate.

While those methods can produce parts in seconds, a single HIP cycle that takes hours might process a few dozen or a few hundred parts, depending on their size.

Understanding the Trade-offs in Precision

While HIP is valued for its ability to densify a part without distorting its overall geometry, it does not guarantee perfect dimensional accuracy.

The Nuance of Shape Change

HIP applies perfectly uniform pressure, which is excellent for closing internal pores without warping a component. However, as the material densifies, it will shrink uniformly.

This predictable shrinkage must be accounted for in the design of the pre-HIP part. It is not a process that can correct major geometric flaws.

The Need for Secondary Machining

The slight, uniform shrinkage and the nature of the pressure application mean that surfaces may not meet the tightest tolerances required for a finished product.

As a result, critical features or surfaces often require subsequent CNC machining to achieve their final, precise dimensions. This adds another step—and additional cost—to the overall production workflow.

Making the Right Choice for Your Goal

Deciding whether to use HIP requires balancing its powerful benefits against its practical limitations. Your final objective is the most important factor.

- If your primary focus is maximum material integrity: HIP is often non-negotiable for critical components in aerospace or medical applications where failure is not an option. Budget for the costs and necessary post-processing.

- If your primary focus is high-volume production: Alternative methods like die compaction, metal injection molding (MIM), or extrusion will be far more cost-effective and faster for less critical parts.

- If your primary focus is achieving a "net shape" with tight tolerances: Use HIP to create a dense, near-net-shape part, but you must design your process with the expectation that final machining will be required.

Understanding these limitations is the first step in leveraging Hot Isostatic Pressing for its intended purpose: creating superior components where performance cannot be compromised.

Summary Table:

| Limitation | Key Impact | Best Suited For |

|---|---|---|

| High Capital & Operational Costs | Significant investment in equipment and energy consumption. | High-value components where performance is critical. |

| Slow Production Cycles | Batch processing with cycle times of several hours. | Low-to-medium volume production, not mass production. |

| Dimensional Accuracy | Predictable shrinkage requires secondary machining for tight tolerances. | Applications where near-net-shape is sufficient or machining is planned. |

Need to achieve maximum material integrity for a critical component?

While HIP has limitations, its ability to eliminate internal defects and create superior material properties is unmatched. KINTEK specializes in lab equipment and consumables, serving the precise needs of laboratories and R&D departments that develop and test high-performance materials.

Let our experts help you determine if HIP is the right solution for your project and guide you to the equipment that meets your specific requirements.

Contact KINTEL today to discuss your application and how we can support your quality and performance goals.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Cylindrical Press Mold with Scale for Lab

People Also Ask

- What is the process of isostatic pressing? Achieve Uniform Density for Complex Parts

- What is an example of cold isostatic pressing? Achieve Uniform Density in Complex Parts

- What advantages does a Cold Isostatic Press (CIP) offer for solid-state batteries? Superior Density & Uniformity

- What is the dry bag process of isostatic pressing? Ideal for High-Volume Production of Simple Shapes

- What is the use of cold isostatic pressing? Achieve Uniform Density for Superior Parts

- Why use cold pressing for Li10SnP2S12 electrolyte pellets? Preserving Stability in Sulfide Electrolytes

- What is the difference between wet bag and dry bag isostatic pressing? Flexibility vs. High-Volume Production

- What is a cold press machine? A Guide to Uniform Powder Compaction Without Heat