Sieve analysis, while a foundational technique, has critical operational boundaries. Its primary limitations stem from providing low-resolution data, its inability to measure particles smaller than approximately 50 micrometers (µm), its requirement for completely dry and free-flowing samples, and a multi-step process that can be surprisingly time-consuming and prone to operator error.

While cost-effective and straightforward, the limitations of sieve analysis are not flaws but inherent characteristics. Its value is maximized in quality control for larger, dry particles, but it is fundamentally unsuited for high-resolution analysis, fine powders below 50 µm, or materials that are wet or prone to agglomeration.

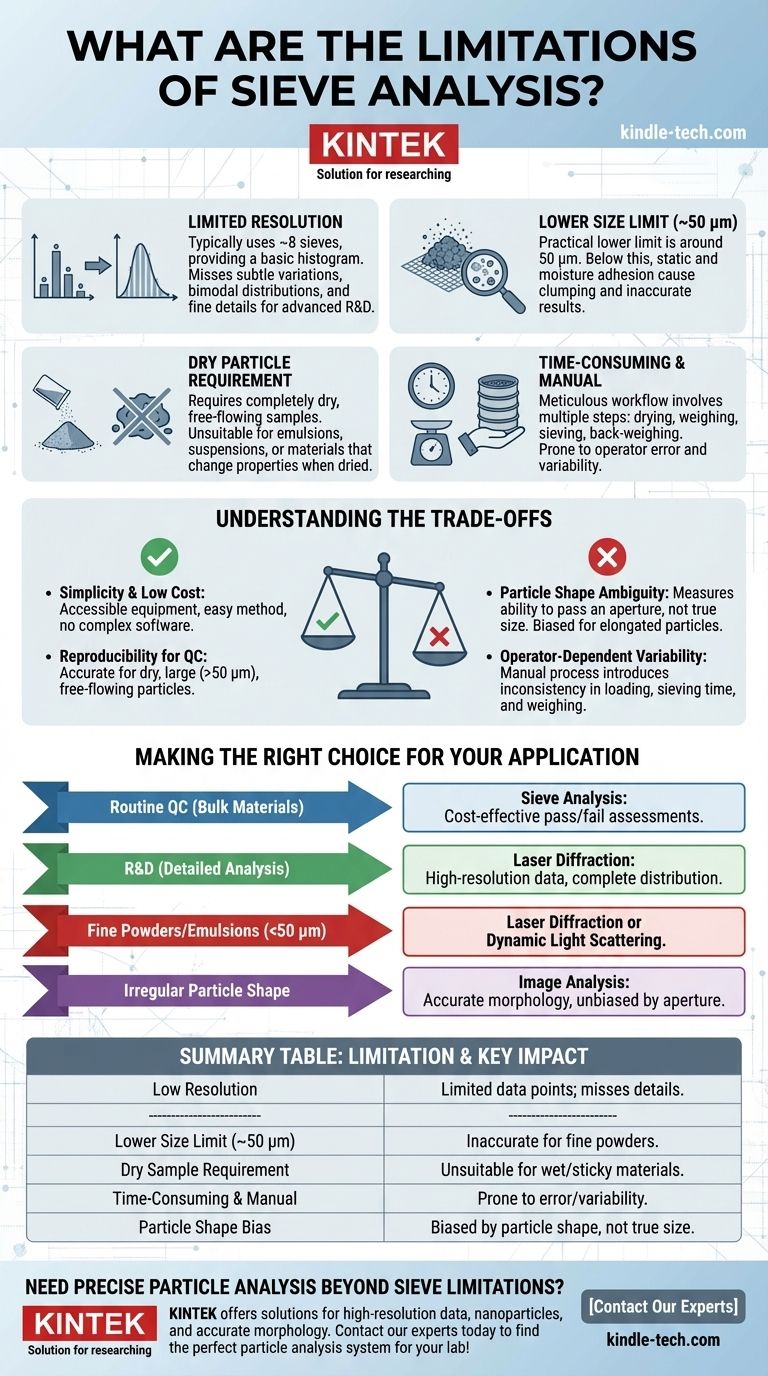

The Core Limitations Explained

To choose the right particle analysis method, you must understand why these limitations exist and what impact they have on your results.

Limited Resolution and Data Granularity

A standard sieve stack uses a maximum of about eight sieves. This means your entire particle size distribution is described by only eight data points.

This provides a basic histogram of your material, which is often sufficient for routine quality checks. However, it cannot reveal subtle variations, bimodal distributions, or the fine details needed for advanced research and development.

The Lower Size Limit

The practical lower limit for sieve analysis is around 50 µm, with some specialized techniques pushing it to 20 µm.

Below this size, forces like static electricity and moisture adhesion become stronger than gravity. Particles clump together and stick to the sieve mesh rather than passing through, rendering the results inaccurate.

The Dry Particle Requirement

Sieve analysis relies on particles moving freely under agitation. This process only works with samples that are thoroughly dried and do not agglomerate.

This limitation makes it unsuitable for analyzing emulsions, suspensions, or materials that change their physical characteristics when dried.

The Process Can Be Deceptively Time-Consuming

While the concept is simple, the official workflow is meticulous. It involves multiple steps: method development, sample preparation (drying), precise weighing of empty sieves, running the test, and then carefully back-weighing each fraction.

Each step introduces time and a potential point for human error, from inconsistent sample division to losing material during transfer.

Understanding the Trade-offs

The limitations of sieve analysis only matter when viewed in context of its distinct advantages and inherent measurement principles.

Advantage: Simplicity and Low Cost

The primary reason for its enduring popularity is its accessibility. The equipment is inexpensive, the method is easy to understand, and it does not require complex software or highly trained specialists.

Disadvantage: Particle Shape Ambiguity

Sieving does not measure a particle's true size; it measures whether a particle can pass through a square opening. An elongated, needle-like particle will be sized by its second-largest dimension, not its longest.

This is a critical bias to be aware of. For applications where particle shape is a crucial performance factor, sieve analysis can be misleading. Image analysis is often a better alternative.

Advantage: Reproducibility for a Specific Goal

For the right kind of material—dry, free-flowing particles larger than 50 µm—sieve analysis provides accurate and repeatable results. It excels at answering the simple question: "What percentage of my material is larger or smaller than a specific size?"

Disadvantage: Operator-Dependent Variability

Because the process is manual, results can vary between operators. Factors like how the sample is loaded, how long the shaker runs, and how carefully the fractions are weighed can all introduce variability, undermining reproducibility if not tightly controlled.

Making the Right Choice for Your Application

Use these limitations to guide your decision on whether sieve analysis is the right tool for your specific goal.

- If your primary focus is routine Quality Control (QC) of bulk materials: Sieve analysis is often the most cost-effective and efficient method for pass/fail assessments against a specification.

- If your primary focus is Research and Development (R&D): The low data resolution is a significant drawback; consider laser diffraction to get a more detailed and complete particle size distribution.

- If your primary focus is analyzing fine powders, nanoparticles, or emulsions: Sieve analysis is fundamentally unsuitable. You must use methods like laser diffraction or dynamic light scattering.

- If your primary focus is characterizing elongated or irregular particles: Be aware that sieving provides a biased result based on a particle's ability to pass an aperture, not its true morphology; consider image analysis for a more accurate understanding.

Understanding these boundaries is the key to leveraging sieve analysis effectively and knowing precisely when to turn to a more advanced method.

Summary Table:

| Limitation | Key Impact |

|---|---|

| Low Resolution | Limited data points (8-10 sieves); misses subtle details. |

| Lower Size Limit (~50 µm) | Inaccurate for fine powders due to particle adhesion. |

| Dry Sample Requirement | Unsuitable for wet, sticky, or agglomerating materials. |

| Time-Consuming & Manual | Prone to operator error and variability. |

| Particle Shape Bias | Measures ability to pass an aperture, not true particle size. |

Need precise particle analysis beyond sieve limitations?

Sieve analysis is a foundational tool, but its constraints in resolution, size range, and material handling can hinder advanced R&D and quality control. KINTEK specializes in providing the right lab equipment and consumables to overcome these challenges.

Whether you need laser diffraction for high-resolution data, dynamic light scattering for nanoparticles, or image analysis for accurate particle morphology, we have the solutions for your laboratory's specific needs.

Contact our experts today to discuss your application and find the perfect particle analysis system to enhance your lab's accuracy and efficiency.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- What are the advantages and disadvantages of sieve analysis? A Guide to Cost-Effective Particle Sizing

- Which Cannot be separated by sieving? Understanding the Limits of Particle Size Separation

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis

- What size are test sieves? A Guide to Frame Diameters and Mesh Sizes

- What is the maximum sieving deviation permitted? A Guide to ASTM & ISO Precision Limits