While annealing is a powerful tool, its primary limitations are a significant reduction in material hardness and strength, high energy consumption due to long heating and cooling cycles, and the potential for undesirable surface oxidation. These factors make it a time-consuming and costly process that isn't suitable for applications where high strength is a critical requirement.

The core trade-off of annealing is straightforward: you gain significant ductility and stress relief at the direct expense of hardness, tensile strength, and process efficiency. Understanding this exchange is crucial for selecting the right heat treatment.

A Quick Refresher: The Goal of Annealing

Annealing is a heat treatment process designed to alter the microstructure of a material, primarily metals, to achieve specific desirable properties. Its main purpose is to make a material softer and more ductile.

The Three Stages

The process involves three distinct stages as the material's temperature is raised and held.

- Recovery: Internal stresses, often induced during manufacturing processes like casting or cold working, are relieved.

- Recrystallization: New, strain-free grains form within the metal's crystalline structure, erasing defects.

- Grain Growth: The newly formed grains begin to grow. This stage, if not properly controlled, can become a liability.

The Annealing Cycle

The cycle involves heating the metal to a specific temperature where its crystal structure can reform, holding it there (a step known as "soaking"), and then cooling it very slowly. This slow cooling is essential for producing the soft, ductile final structure.

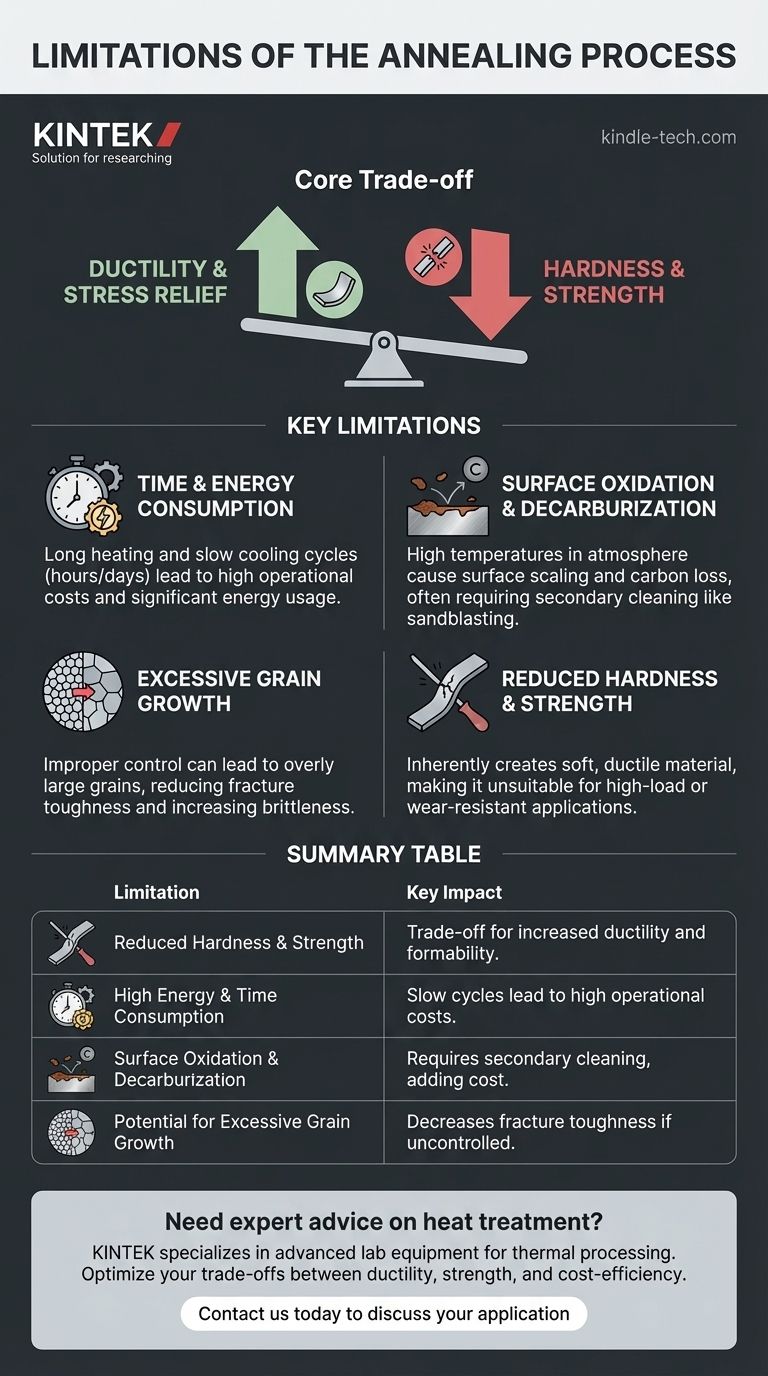

Key Limitations of the Annealing Process

While effective, annealing is not a universal solution. Its drawbacks are significant and must be weighed against its benefits.

Significant Reduction in Hardness and Strength

This is the most critical metallurgical trade-off. By creating a soft and ductile microstructure, annealing inherently reduces the material's hardness and tensile strength. The resulting material is easier to bend and shape but cannot withstand high loads or resist wear as effectively.

Time and Energy Consumption

The requirement for slow, controlled heating and especially slow cooling makes annealing a very long process. A component may need to spend many hours, or even days, inside a furnace. This extended furnace time translates directly into high energy consumption.

High Operational Costs

Time and energy are expensive. The combination of long furnace cycles and high energy usage makes full annealing one of the more costly heat treatment processes compared to alternatives like normalizing or stress relieving at a lower temperature.

Potential for Excessive Grain Growth

If the soaking temperature is too high or the time is too long, the grains can grow excessively large. While a uniform grain structure is desired, overly large grains can decrease properties like fracture toughness, making the material more prone to brittle failure under certain conditions.

Surface Oxidation and Decarburization

Heating metals to high temperatures in an atmosphere containing oxygen will inevitably cause surface scaling or oxidation. For carbon steels, it can also cause decarburization (loss of carbon from the surface), which softens the exterior skin. These surface effects often necessitate secondary cleaning operations like sandblasting or acid pickling, adding another step and cost to the manufacturing chain.

Understanding the Trade-offs: Ductility vs. Strength

The decision to anneal is fundamentally a choice between ductility and strength. You are intentionally "resetting" the material to its softest, most workable state.

This is highly desirable when a component needs to undergo significant plastic deformation, such as deep drawing a sheet metal part or complex machining of a tough alloy. The improved machinability and formability can reduce tool wear and prevent cracking during fabrication.

However, if the final component needs to be hard, strong, or wear-resistant, annealing is often just an intermediate step. The part would likely need to be re-hardened through a subsequent heat treatment process, like quenching and tempering.

Is Annealing the Right Choice for Your Application?

Choosing a heat treatment requires aligning the process with your end goal.

- If your primary focus is maximum machinability or formability: Annealing is often the correct, and sometimes necessary, choice to prepare the material for fabrication.

- If your primary focus is component strength and hardness: Annealing is the wrong final step; consider normalizing for a balance of properties or a quench and temper process for maximum hardness.

- If your primary focus is simply relieving internal stress with minimal impact on strength: A lower-temperature stress relief cycle, which does not enter the recrystallization phase, is a much more efficient and effective option than a full anneal.

Ultimately, you must treat annealing as a specific tool for softening a material, accepting the inherent loss of strength as the price for improved ductility.

Summary Table:

| Limitation | Key Impact |

|---|---|

| Reduced Hardness & Strength | Trade-off for increased ductility and formability. |

| High Energy & Time Consumption | Slow heating/cooling cycles lead to high operational costs. |

| Surface Oxidation & Decarburization | Can require secondary cleaning processes, adding cost. |

| Potential for Excessive Grain Growth | May decrease fracture toughness if not properly controlled. |

Need expert advice on selecting the right heat treatment process for your materials?

The limitations of annealing highlight the importance of choosing a process that aligns perfectly with your component's performance requirements. At KINTEK, we specialize in providing advanced lab equipment and consumables for precise thermal processing. Our experts can help you navigate the trade-offs between ductility, strength, and cost-efficiency to optimize your results.

Contact us today via our [#ContactForm] to discuss your specific application and discover how KINTEK's solutions can enhance your laboratory's capabilities and ensure your heat treatment processes are both effective and economical.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the vacuum heat treatment cycle? Achieve Superior Material Purity and Precision

- What is vacuum heat treatment process? Achieve Superior Control, Cleanliness, and Quality

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- What are vacuum furnace parts? A Guide to the Core Systems for Precision Heat Treatment

- What does a vacuum furnace do? Achieve High-Purity Heat Treatment for Superior Components