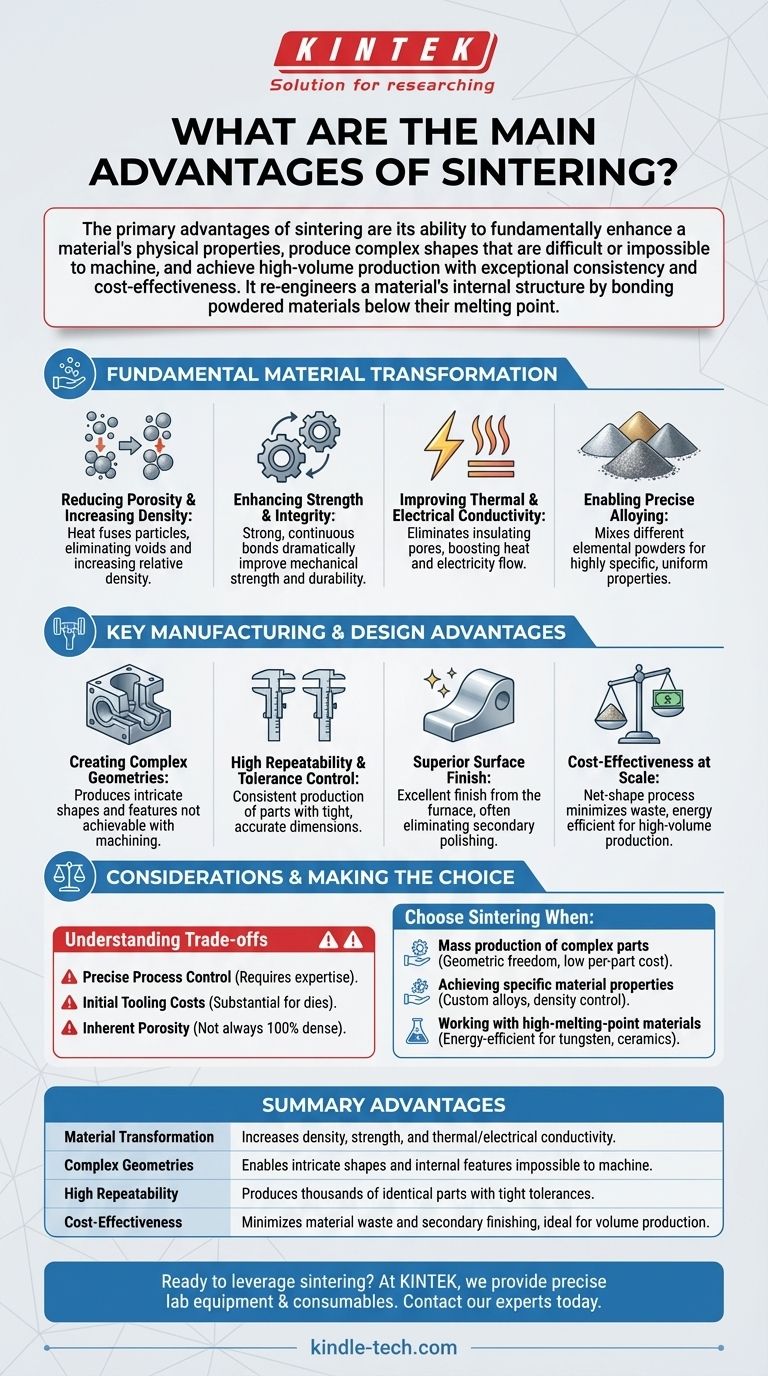

The primary advantages of sintering are its ability to fundamentally enhance a material's physical properties, produce complex shapes that are difficult or impossible to machine, and achieve high-volume production with exceptional consistency and cost-effectiveness. By bonding powdered materials together with heat below their melting point, this process creates strong, dense parts while minimizing material waste and the need for secondary finishing operations.

Sintering is more than a manufacturing step; it is a transformative process that re-engineers a material's internal structure. It allows for the creation of components with unique properties and complex geometries that are often unattainable through traditional melting or machining methods.

How Sintering Fundamentally Transforms Materials

The true power of sintering lies in its ability to control a material's microstructure. The process uses thermal energy to drive atomic diffusion, fundamentally changing how individual particles are bonded together.

Reducing Porosity and Increasing Density

The initial material, a compacted powder, is filled with tiny voids between particles. During sintering, heat causes these particles to fuse, forming "sintered necks" that grow and pull the particles closer together.

This atomic-level bonding systematically eliminates pores, significantly increasing the part's relative density.

Enhancing Strength and Integrity

As porosity decreases and density increases, the material's mechanical strength and overall integrity improve dramatically. The strong, continuous bonds created between particles make the final part far more durable and resistant to fracture than the original powder compact.

Improving Thermal and Electrical Conductivity

Pores and voids act as insulators, hindering the flow of heat and electricity. By eliminating these gaps and creating a denser, more continuous material structure, sintering significantly improves both thermal and electrical conductivity.

Enabling Precise Alloying

Sintering provides an exceptional method for creating alloys. Different elemental powders (like nickel, copper, or graphite) can be mixed and then diffused into the primary material during the heating cycle, resulting in a final part with highly specific and uniformly distributed properties.

Key Manufacturing and Design Advantages

Beyond improving material properties, sintering offers distinct advantages in the production environment, particularly for manufacturing at scale.

Creating Complex Geometries

Sintering excels at producing parts with intricate shapes, internal channels, or non-machinable features. Since the initial shape is formed by compacting powder in a die, it enables a level of design freedom that is cost-prohibitive or impossible with subtractive methods like machining.

High Repeatability and Tolerance Control

The process is exceptionally repeatable. Once the tooling and process parameters are established, sintering can produce thousands or millions of parts with very tight and consistent dimensional tolerances, ensuring high part-to-part accuracy.

Superior Surface Finish

Sintered parts often come out of the furnace with an excellent surface finish that requires no additional polishing or grinding. This eliminates costly and time-consuming secondary finishing steps, streamlining the production workflow.

Cost-Effectiveness at Scale

Sintering is an incredibly efficient process. It is a net-shape (or near-net-shape) process, meaning there is very little material waste compared to machining. Furthermore, operating below the material's melting point consumes less energy than casting. These factors combine to make it highly cost-effective for medium- to high-volume production runs.

Understanding the Trade-offs and Considerations

While powerful, sintering is not a universal solution. Being an effective advisor means understanding its limitations and the precision required to achieve good results.

The Need for Precise Process Control

The final properties of a sintered part are highly sensitive to process variables like temperature, time, and furnace atmosphere. Deviations can lead to undersintering (weak, porous parts) or oversintering (distortion and poor dimensional control), making expertise and process control critical.

Initial Tooling Costs

The powder metallurgy process, which relies on sintering, requires the creation of robust dies to compact the powder. This initial tooling investment can be substantial, making the process less economical for very low-volume or one-off prototypes.

Inherent Porosity

While sintering drastically reduces porosity, achieving 100% density can be difficult without secondary operations. For some critical, high-stress applications, the performance of a sintered part may not match that of a fully dense wrought or forged equivalent. However, for applications like filters, this controlled porosity is a key design feature.

Making the Right Choice for Your Goal

Selecting sintering depends entirely on your project's specific priorities regarding material properties, part complexity, and production volume.

- If your primary focus is mass production of complex parts: Sintering offers an unmatched combination of geometric freedom, high repeatability, and low per-part cost at scale.

- If your primary focus is achieving specific material properties: Sintering provides a unique ability to create custom alloys and control density to optimize for strength, conductivity, or even controlled porosity.

- If your primary focus is working with high-melting-point materials: Sintering is one of the most effective and energy-efficient methods for processing materials like tungsten or ceramics without having to fully melt them.

Ultimately, sintering provides a powerful pathway to engineer and manufacture high-performance components with a unique combination of material precision, geometric freedom, and economic efficiency.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Material Transformation | Increases density, strength, and thermal/electrical conductivity. |

| Complex Geometries | Enables intricate shapes and internal features impossible to machine. |

| High Repeatability | Produces thousands of identical parts with tight tolerances. |

| Cost-Effectiveness | Minimizes material waste and secondary finishing, ideal for volume production. |

Ready to leverage sintering for your lab's manufacturing or R&D projects?

At KINTEK, we specialize in providing the precise lab equipment and consumables needed to master the sintering process. Whether you are developing new materials, producing complex components, or scaling up production, our expertise and reliable solutions ensure you achieve consistent, high-quality results.

Contact our experts today via our Contact Form to discuss how we can support your specific sintering needs and help you unlock the full potential of this transformative manufacturing method.

Visual Guide

Related Products

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- What is the function of a laboratory high-temperature hydraulic press? Optimize MEA Fabrication for HCl Electrolysis

- What is a heated hydraulic press used for? Essential Tool for Curing, Molding, and Laminating

- What technical conditions does a heated hydraulic press provide for PEO batteries? Optimize Solid-State Interfaces

- What is a hot hydraulic press? Harness Heat and Pressure for Advanced Manufacturing

- How much force can a hydraulic press exert? Understanding its immense power and design limits.