The primary drawbacks of a direct core type induction furnace are its operational inflexibility and strict material requirements. These furnaces must run continuously with a molten metal charge, making them unsuitable for intermittent work or frequent alloy changes. Furthermore, they possess no refining capability, meaning the charge material must be clean and of a known, precise composition before being introduced.

A core type induction furnace exchanges operational flexibility for exceptional energy efficiency. Its design demands a continuous, single-alloy production environment, making it a highly specialized tool rather than a versatile one.

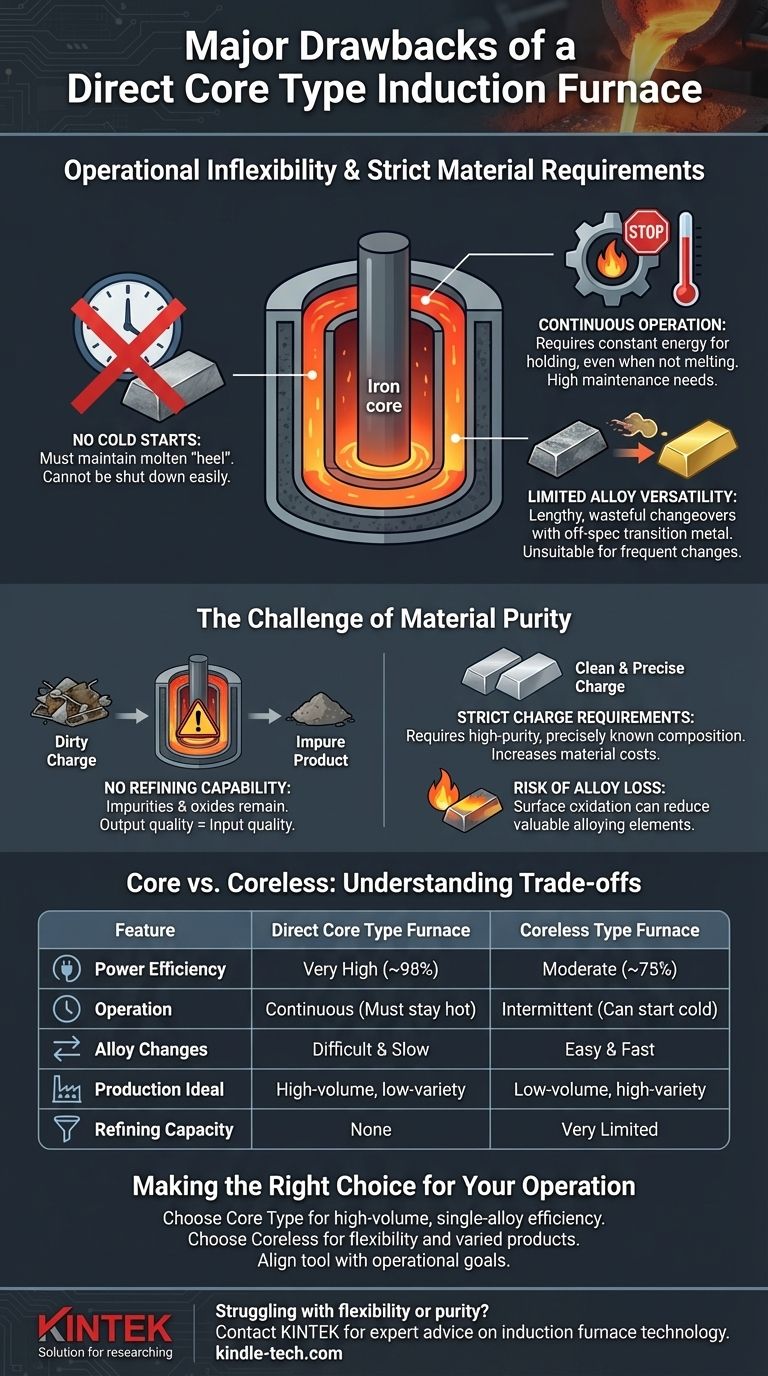

The Fundamental Drawback: Operational Inflexibility

The core type furnace's design, where the molten metal forms a closed loop acting as the transformer's secondary coil, is the source of both its efficiency and its rigidity.

The "Never-Stop" Requirement

A core type furnace cannot be started cold with solid material. It requires an initial charge of molten metal to complete the electrical circuit.

Because of this, the furnace is almost never shut down. Letting the metal solidify would break the circuit loop, requiring a difficult and time-consuming restart process with a new "heel" of molten metal.

This "always-on" nature results in continuous energy consumption, even when the furnace is not actively melting new material, just to maintain the molten bath.

Limited Alloy Versatility

Switching metal alloys is a significant operational challenge. A substantial portion of the old alloy must be drained and replaced with the new one, leading to a lengthy changeover period and the creation of off-spec "transition" metal.

This makes the furnace highly impractical for operations that require frequent changes in alloy specification, such as foundries producing a wide variety of small-batch products.

The Need for Continuous Maintenance

The channel or loop containing the molten metal is subject to wear and requires constant monitoring and eventual maintenance. This need for continuous upkeep is a direct consequence of its continuous operation.

The Challenge of Material Purity

Unlike other furnace types that can help purify the metal, a core type induction furnace is purely a melter. The quality of the output is almost entirely dependent on the quality of the input.

No Refining Capability

The furnace offers no practical way to remove impurities like oxides or slag from the charge material. There is no inherent process for refining the melt.

This means that any contaminants introduced with the charge materials will remain in the final product, potentially compromising its metallurgical properties.

Strict Charge Material Requirements

To ensure final product quality, all charge materials must be clean, dry, and free of oxides. This requirement can increase the cost and complexity of sourcing raw materials.

The chemical composition of the charge must also be precisely known and controlled, as the furnace itself provides no means to adjust it other than by adding more alloys.

Risk of Alloy Loss

While it is not a refining furnace, some level of oxidation can still occur on the surface of the melt. This can lead to the loss of valuable and easily oxidized alloying elements, which may need to be measured and replenished to meet final specifications.

Understanding the Trade-offs: Core vs. Coreless

Choosing a furnace requires understanding the fundamental compromises between different induction technologies. The direct core type furnace stands in stark contrast to the coreless type.

| Feature | Direct Core Type Furnace | Coreless Type Furnace |

|---|---|---|

| Power Efficiency | Very High (~98%) | Moderate (~75%) |

| Operation | Continuous (must stay hot) | Intermittent (can start cold) |

| Alloy Changes | Difficult and slow | Easy and fast |

| Production Ideal | High-volume, low-variety | Low-volume, high-variety |

| Refining Capacity | None | Very limited |

Making the Right Choice for Your Operation

The decision to use a direct core type furnace hinges entirely on your production model.

- If your primary focus is high-volume, single-alloy production: The unmatched energy efficiency (up to 98%) of a core type furnace makes it the superior financial and operational choice.

- If your primary focus is flexibility or producing varied products: The ability of a coreless furnace to be shut down and handle frequent alloy changes is non-negotiable.

- If your primary focus is melting lower-purity scrap: Neither furnace is ideal, but a coreless furnace offers slightly more tolerance and is easier to clean between melts.

Ultimately, selecting the correct furnace is about aligning the tool's inherent strengths and weaknesses with your specific operational goals.

Summary Table:

| Drawback | Impact on Operation |

|---|---|

| Operational Inflexibility | Must run continuously; unsuitable for intermittent work or frequent alloy changes. |

| No Refining Capability | Charge material must be clean and of precise composition; impurities remain in final product. |

| Strict Material Requirements | Increases cost and complexity of sourcing raw materials. |

| Continuous Maintenance | Channel wear requires constant monitoring and upkeep due to continuous operation. |

Struggling with furnace flexibility or material purity in your lab or foundry? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you select the right induction furnace technology—whether core type for high-volume efficiency or coreless for versatile alloy changes—to optimize your production goals. Contact us today to discuss your specific requirements and enhance your operational efficiency!

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is vacuum arc melting technique? Discover the Precision of Vacuum Induction Melting

- How does induction work in a vacuum? Achieve Ultra-Pure Metal Melting with VIM

- What is the principle of vacuum induction melting? Achieve Ultra-High Purity Metals

- What is the primary function of a vacuum induction melting furnace? Melt High-Purity Metals with Precision

- What types of metals are typically processed in a vacuum induction melting furnace? High-Purity Alloys for Critical Applications