At its core, Physical Vapor Deposition (PVD) is a family of vacuum deposition techniques, not a single process. The primary methods used in PVD are broadly classified into two main categories: Evaporation, where a material is thermally vaporized, and Sputtering, where atoms are physically ejected from a target by ion bombardment. Other significant techniques include Arc Evaporation and Pulsed Laser Deposition, each distinguished by its unique method of generating material vapor.

The critical distinction between PVD methods is not which is "better," but how they generate vapor. Your choice depends on the material you are depositing, the energy of the deposited particles, and the final film properties you need to achieve, such as density, adhesion, and purity.

The Fundamental Principle of PVD

All PVD techniques share a common three-step process that occurs inside a vacuum chamber. Understanding this framework is key to seeing how the different methods relate to one another.

Step 1: Vaporization

A solid source material, known as the "target," is converted into a gaseous or vapor phase. This is the defining step where the various PVD methods diverge, using different physical mechanisms to liberate atoms from the source.

Step 2: Transport

The vaporized atoms or molecules travel across the low-pressure vacuum chamber from the source to the object being coated, known as the "substrate." The vacuum is crucial because it prevents these particles from colliding with air molecules.

Step 3: Condensation

The vapor condenses on the substrate, building up layer by layer to form a thin, solid film. The energy and properties of the arriving particles directly influence the structure and characteristics of the final coating.

The Two Pillars of PVD: Evaporation vs. Sputtering

The vast majority of PVD applications use either evaporation or sputtering. They represent two fundamentally different approaches to the vaporization step.

Evaporation: "Boiling" a Material onto a Surface

Evaporation methods use heat to raise the vapor pressure of a source material until it effectively boils, releasing atoms that then coat the substrate.

Thermal Evaporation (Resistive Heating)

This is the simplest method. A high electrical current is passed through a refractory metal boat or filament containing the source material, causing it to heat up and evaporate. It is fast and cost-effective for certain materials like aluminum and gold.

Electron Beam Evaporation (E-Beam PVD)

A high-energy beam of electrons is focused on the source material, heating a localized spot to extremely high temperatures. This allows for the deposition of materials with very high melting points (like titanium or ceramics) and results in higher-purity films than thermal evaporation.

Sputtering: An Atomic-Scale Billiard Ball Collision

Sputtering does not rely on heat. Instead, it uses momentum transfer to dislodge atoms from the target, much like a cue ball breaking a rack of billiard balls.

Magnetron Sputtering

This is the most widely used sputtering technique in industry. A high voltage is applied to the target, creating a plasma of inert gas (like Argon). Magnets behind the target trap electrons near its surface, dramatically increasing the efficiency of ion formation. These ions then bombard the target, ejecting atoms that deposit onto the substrate.

Reactive Sputtering

This is a variation where a reactive gas, such as nitrogen or oxygen, is intentionally introduced into the vacuum chamber along with the sputtering gas. The sputtered metal atoms react with this gas on their way to the substrate, forming compound films like titanium nitride (TiN) or silicon dioxide (SiO₂).

Beyond the Main Two: Specialized PVD Methods

While less common than evaporation or sputtering, other methods offer unique advantages for specific applications.

Arc Evaporation (Cathodic Arc)

A high-current, low-voltage electric arc is struck on the target surface. The intense energy of the arc spot vaporizes the cathode material directly, creating a highly ionized plasma. This results in extremely dense and well-adhered coatings, making it ideal for hard, wear-resistant tool coatings.

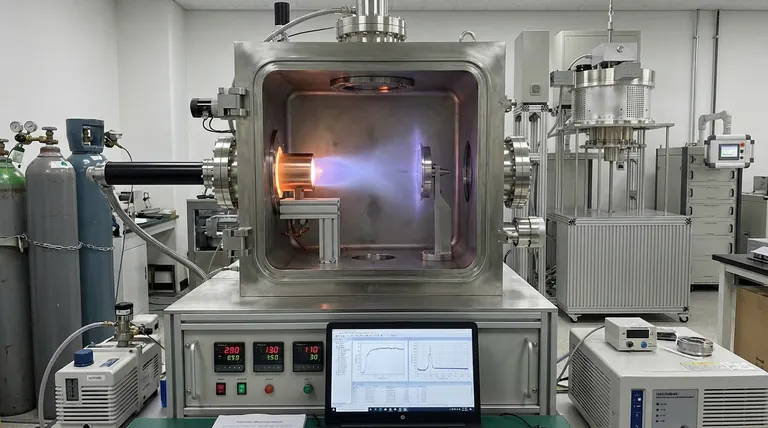

Pulsed Laser Deposition (PLD)

A high-power, pulsed laser is focused onto the target in a vacuum. Each laser pulse ablates, or vaporizes, a small amount of the material, creating a plume of plasma that deposits on the substrate. PLD is a powerful research tool for depositing complex materials while preserving their chemical composition (stoichiometry).

Understanding the Trade-offs

No single PVD method is universally superior. The right choice involves balancing complexity, cost, and the desired outcome.

Evaporation: Speed and Simplicity

Evaporation is generally faster and uses simpler equipment than sputtering. However, the deposited atoms have low energy, which can result in poorer film adhesion and lower density compared to sputtered films.

Sputtering: Control and Quality

Sputtering provides excellent control over film thickness, uniformity, and composition. The higher energy of sputtered atoms promotes better adhesion and denser film growth, making it ideal for optical and electronic applications. The trade-off is often slower deposition rates and more complex equipment.

Arc Deposition: Density vs. Defects

Arc deposition produces the highest-energy particles, leading to exceptionally hard and dense films. However, the process can also eject larger clusters of atoms or "macro-particles," which can be undesirable defects in the coating.

Selecting the Right PVD Method

Your application's goal will dictate the most appropriate technique.

- If your primary focus is rapid deposition of simple metals for reflective coatings: Thermal evaporation is often the most direct and cost-effective choice.

- If your primary focus is high-quality, dense, and uniform films for electronics or optics: Magnetron sputtering offers superior control over adhesion and film properties.

- If your primary focus is creating extremely hard, wear-resistant coatings for cutting tools: Arc evaporation is a leading industrial method for its ability to produce dense, durable films.

- If your primary focus is research and development of novel, complex oxide or ceramic films: Pulsed Laser Deposition (PLD) provides unique capabilities for transferring material composition accurately.

Ultimately, choosing a PVD method is about matching the physics of the deposition process to the required performance of the final film.

Summary Table:

| PVD Method | Vaporization Mechanism | Key Characteristics | Best For |

|---|---|---|---|

| Thermal Evaporation | Resistive heating | Fast, simple, cost-effective | Rapid deposition of simple metals (e.g., Al, Au) |

| E-Beam Evaporation | Electron beam heating | High-purity, high-melting-point materials | Depositing high-purity films (e.g., Ti, ceramics) |

| Magnetron Sputtering | Ion bombardment (momentum transfer) | Excellent control, uniform, dense films | Electronics, optics, high-quality coatings |

| Arc Evaporation | Electric arc | Extremely dense, hard, well-adhered coatings | Wear-resistant tool coatings |

| Pulsed Laser Deposition (PLD) | Laser ablation | Preserves complex material composition | R&D of novel oxides/ceramics |

Ready to choose the right PVD method for your lab? At KINTEK, we specialize in providing high-quality lab equipment and consumables for all your PVD needs. Whether you're working on thin-film research, optical coatings, or durable tool coatings, our experts can help you select the perfect system to achieve superior film properties like adhesion, density, and purity. Contact us today to discuss your specific application and discover how KINTEK can enhance your laboratory's capabilities!

Visual Guide

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Anti-Cracking Press Mold for Lab Use

People Also Ask

- What is MPCVD method? A Guide to High-Purity Diamond Synthesis

- What is the frequency of MPCVD? A Guide to Choosing 2.45 GHz vs. 915 MHz for Your Application

- What are the limitations of diamonds? Beyond the Myth of Perfection

- What are the advantages of microwave plasma? Faster, Purer Processing for Demanding Applications

- How does MPCVD work? A Guide to Low-Temperature, High-Quality Film Deposition