At its core, infrared (IR) spectroscopy is a measurement of how a sample absorbs infrared light. The specific method used is determined almost entirely by the physical state of that sample—whether it is a solid, a liquid, or a gas. For solids, common methods include the KBr pellet, mull, and cast film techniques, while liquids are often analyzed directly between salt plates.

The central challenge in infrared spectroscopy isn't the instrument, but the preparation. The goal is always the same: to get a thin, uniform layer of your sample into the instrument's beam path without introducing interfering signals from the preparation medium itself.

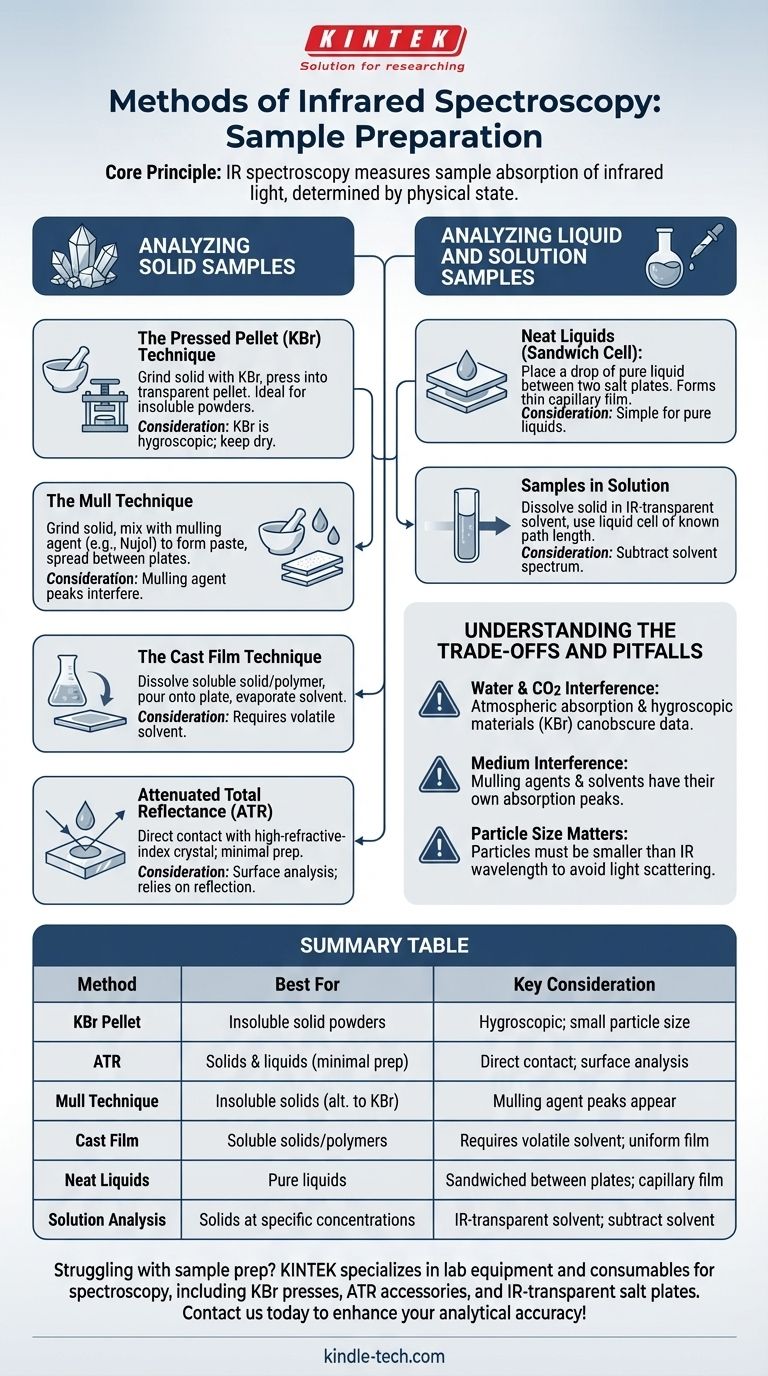

Analyzing Solid Samples

Preparing a solid for IR analysis is often the most involved process because the sample must be made partially transparent to infrared radiation. If the solid particles are too large, they will scatter the light, leading to a poor-quality spectrum.

The Pressed Pellet (KBr) Technique

This is a classic and widely used method. A small amount of the solid sample is finely ground with a high-purity alkali halide, most commonly potassium bromide (KBr).

The mixture is then pressed under high pressure in a die to form a small, transparent pellet. This pellet can be placed directly in the spectrometer's sample holder.

The Mull Technique

In the mull technique, the solid sample is ground into a fine powder and then mixed with a few drops of a mulling agent (like Nujol, a mineral oil) to create a thick paste.

This paste is then spread thinly between two IR-transparent salt plates (like NaCl or KBr). The primary drawback is that the spectrum will show absorption bands from the mulling agent, which can obscure parts of the sample's spectrum.

The Cast Film Technique

This method is reserved for solids that can be easily dissolved in a volatile solvent, such as polymers.

The sample is dissolved, and the solution is poured onto a flat salt plate. The solvent is then allowed to evaporate, leaving behind a thin, uniform film of the solid sample on the plate for analysis.

Attenuated Total Reflectance (ATR)

A more modern and often simpler method is ATR. This technique requires very little sample preparation. The solid (or liquid) is simply pressed into direct contact with a high-refractive-index crystal.

The IR beam is passed through the crystal in such a way that it reflects internally. At each reflection point, the beam penetrates a tiny amount into the sample, generating a spectrum from the surface layer.

Analyzing Liquid and Solution Samples

Liquids are generally much simpler to analyze than solids because they can easily form the thin, uniform layer required for measurement.

Neat Liquids (Sandwich Cell)

For pure liquids (referred to as "neat" samples), the process is straightforward. A single drop of the liquid is placed on one salt plate, and a second plate is carefully placed on top.

The liquid spreads to form a thin capillary film between the plates. This "sandwich" is then mounted and analyzed directly.

Samples in Solution

If a solid sample is soluble, it can be analyzed in solution. The sample is dissolved in a solvent that has minimal absorption in the spectral region of interest (e.g., carbon tetrachloride or chloroform).

The solution is then placed in a special liquid cell of a known path length and analyzed. A spectrum of the pure solvent must also be run and subtracted from the sample's spectrum to isolate the signal of the solute.

Understanding the Trade-offs and Pitfalls

Choosing a method involves understanding its limitations. The quality of your spectrum is directly dependent on the quality of your sample preparation.

The Problem of Water and CO2

Atmospheric water vapor and carbon dioxide have strong IR absorptions. KBr is also hygroscopic, meaning it readily absorbs moisture from the air. This can introduce large, broad water peaks that obscure the sample's data, especially in the KBr pellet method.

Interference from the Medium

The mulling agent in the mull technique and the solvent used for solutions will have their own IR absorption peaks. You must be aware of where these peaks are to avoid misinterpreting them as belonging to your sample.

Particle Size Matters

For solid samples prepared via the mull or KBr pellet methods, it is critical that the sample is ground into particles that are smaller than the wavelength of the infrared light. If particles are too large, they cause significant light scattering, which distorts the spectrum and makes interpretation difficult.

Selecting the Right Method for Your Sample

Your choice of method should be a direct response to the physical nature of your sample and your analytical goals.

- If your primary focus is an insoluble solid powder: ATR is the fastest and most modern approach, but the KBr pellet and mull techniques are reliable traditional methods.

- If your primary focus is a soluble solid or polymer: The cast film technique is excellent for creating a uniform sample without interfering signals from a mulling agent.

- If your primary focus is a pure liquid: A neat sample prepared between two salt plates is the simplest and most direct method.

- If your primary focus is analyzing a substance at a specific concentration: Preparing a solution and using a liquid cell is the most appropriate technique.

Properly matching your sample preparation technique to your material is the first and most critical step in acquiring a meaningful infrared spectrum.

Summary Table:

| Method | Best For | Key Consideration |

|---|---|---|

| KBr Pellet | Insoluble solid powders | Hygroscopic; grind particles smaller than IR wavelength |

| ATR | Solids & liquids (minimal prep) | Direct contact with crystal; surface analysis |

| Mull Technique | Insoluble solids (alternative to KBr) | Mulling agent (e.g., Nujol) peaks appear in spectrum |

| Cast Film | Soluble solids/polymers | Requires volatile solvent; uniform film after evaporation |

| Neat Liquids | Pure liquids | Sandwiched between salt plates; forms thin capillary film |

| Solution Analysis | Solids at specific concentrations | Use IR-transparent solvent; subtract solvent spectrum |

Struggling with sample prep for accurate IR spectroscopy results? KINTEK specializes in lab equipment and consumables for spectroscopy, including presses for KBr pellets, ATR accessories, and IR-transparent salt plates. Our expertise ensures you get clear, interpretable spectra by matching the right preparation technique to your sample. Contact us today (#ContactForm) to discuss your laboratory needs and enhance your analytical accuracy!

Visual Guide

Related Products

- Infrared High Resistance Single Crystal Silicon Lens

- Optical Window Glass Substrate Wafer Barium Fluoride BaF2 Substrate Window

- Thin-Layer Spectral Electrolysis Electrochemical Cell

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

People Also Ask

- What is the purpose of using a laboratory hydraulic press for polyricinoleate films? Ensure Precision Density

- What is the function of a laboratory hydraulic press in electrode preparation? Enhance Sodium Battery Anode Performance

- What is the primary purpose of a uniaxial hydraulic press for sulfide electrolytes? Optimize Ionic Conductivity Tests

- What function does a uniaxial hydraulic press serve in LATP ceramic preparation? Optimize Your Solid Electrolytes

- What is the role of a laboratory hydraulic press in evaluating concrete? Test Eggshell Additive Performance

- What is the role of a high-tonnage laboratory hydraulic press in sulfide electrolyte preparation? Achieve 82% Density

- What role does a laboratory hydraulic press play in electrode sheets? Optimize Connectivity & Stability

- How does a laboratory hydraulic press contribute to the preparation of shaped Fischer-Tropsch Synthesis catalysts?