While several methods exist, the production of carbon nanotubes (CNTs) is dominated by one primary industrial process: Chemical Vapor Deposition (CVD). Older techniques like arc discharge and laser ablation were foundational but are not used for large-scale commercial production. Meanwhile, innovative new methods like methane pyrolysis are emerging to meet demands for greener manufacturing.

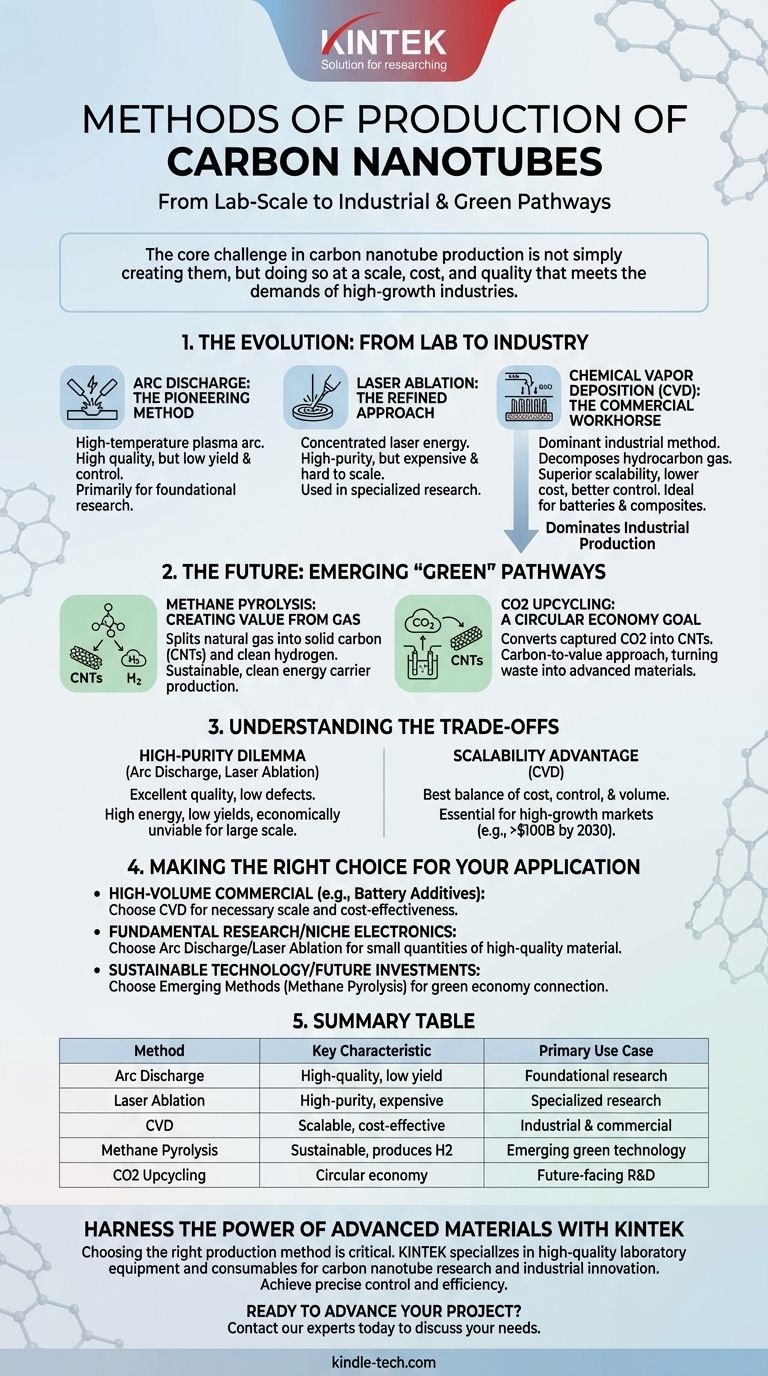

The core challenge in carbon nanotube production is not simply creating them, but doing so at a scale, cost, and quality that meets the demands of high-growth industries like lithium-ion batteries and advanced composites. This makes the choice of production method a critical strategic decision.

The Evolution of Production: From Lab to Industry

The methods used to synthesize carbon nanotubes have evolved significantly, moving from high-energy, lab-scale techniques to scalable industrial processes.

Arc Discharge: The Pioneering Method

The arc discharge method was one of the first techniques used to produce CNTs. It involves creating a high-temperature plasma arc between two graphite electrodes, which vaporizes the carbon to form nanotubes. While it can produce high-quality CNTs, the process has low yield and offers little control over the final structure.

Laser Ablation: The Refined Approach

Similar to arc discharge, laser ablation uses a concentrated energy source—in this case, a laser—to vaporize a graphite target. This technique is known for producing high-purity CNTs but is expensive and difficult to scale, limiting its use primarily to research applications.

Chemical Vapor Deposition (CVD): The Commercial Workhorse

CVD is the dominant method for commercial CNT production today. The process involves decomposing a hydrocarbon gas (like methane) over a metal catalyst, causing carbon atoms to assemble into nanotube structures. Its dominance stems from its superior scalability, lower operating temperatures, and better control over the resulting nanotube length and diameter.

The Future of Production: Emerging "Green" Pathways

As demand for sustainable manufacturing grows, new production routes are being developed that utilize waste or create additional value streams.

Methane Pyrolysis: Creating Value from Gas

Methane pyrolysis splits natural gas into two valuable products: solid carbon (including CNTs) and clean-burning hydrogen gas. This process is gaining significant attention because it produces a highly valuable nanomaterial while also generating a clean energy carrier without releasing carbon dioxide.

CO2 Upcycling: A Circular Economy Goal

Another emerging area involves using captured carbon dioxide as a feedstock. Through processes like electrolysis in molten salts, CO2 can be converted into solid carbon forms, including CNTs. This represents a powerful "carbon-to-value" approach, turning a waste product into an advanced material.

Understanding the Trade-offs

Choosing a production method involves a critical balance between the quality of the nanotubes, the volume required, and the overall cost.

The High-Purity Dilemma

Arc discharge and laser ablation excel at producing CNTs with very few defects. However, their high energy requirements and low yields make them economically unviable for the large quantities needed for applications like battery electrodes or polymer composites.

The Scalability Advantage of CVD

CVD provides the best balance of cost, control, and volume. This makes it the only practical choice for industrial players looking to supply the rapidly growing market, which is projected to reach over $100 billion by 2030 for some carbon nanomaterials.

The Promise of New Methods

Emerging techniques like methane pyrolysis offer a compelling sustainable narrative. However, they must still prove their ability to compete with the established efficiency and scale of CVD to achieve widespread commercial adoption.

Making the Right Choice for Your Application

The optimal production method is ultimately defined by the end-use application and its specific performance and cost requirements.

- If your primary focus is high-volume commercial products like battery additives or conductive polymers: Chemical Vapor Deposition (CVD) is the only method that currently provides the necessary scale and cost-effectiveness.

- If your primary focus is fundamental research or niche electronics requiring maximum purity: Arc discharge and laser ablation remain valuable for producing small quantities of high-quality material for specialized use.

- If your primary focus is sustainable technology and future-facing investments: Emerging methods like methane pyrolysis represent the next frontier, connecting advanced materials production to the clean energy economy.

Ultimately, understanding the link between production method and material properties is essential to harnessing the transformative potential of carbon nanotubes.

Summary Table:

| Method | Key Characteristic | Primary Use Case |

|---|---|---|

| Arc Discharge | High-quality, low yield | Foundational research |

| Laser Ablation | High-purity, expensive | Specialized research |

| Chemical Vapor Deposition (CVD) | Scalable, cost-effective | Industrial & commercial (e.g., batteries) |

| Methane Pyrolysis | Sustainable, produces hydrogen | Emerging green technology |

| CO2 Upcycling | Circular economy approach | Future-facing R&D |

Harness the Power of Advanced Materials with KINTEK

Choosing the right production method is critical to unlocking the full potential of carbon nanotubes for your application. Whether you are scaling up a commercial product or pioneering sustainable research, having the right lab equipment is the first step.

KINTEK specializes in providing high-quality laboratory equipment and consumables to support your work with carbon nanotubes and other advanced materials. We help our customers in research and industry achieve precise control, efficiency, and innovation.

Ready to advance your project? Contact our experts today to discuss how our solutions can meet your specific laboratory needs and drive your success.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What are the advantages of using HFCVD for BDD electrodes? Scaling Industrial Diamond Production Efficiently

- How are reactants introduced into the reaction chamber during a CVD process? Mastering Precursor Delivery Systems

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production

- How does a Hot Filament Chemical Vapor Deposition (HFCVD) reactor function? Expert Guide to Diamond Film Fabrication

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies