At its core, Physical Vapor Deposition (PVD) is a family of coating methods, not a single process. The primary methods fall into two main categories: sputtering, where atoms are physically ejected from a target material, and thermal evaporation, where a material is heated until it vaporizes. Variations like magnetron sputtering, reactive sputtering, and electron-beam evaporation are used to control the properties of the final coating.

The specific PVD method chosen is a critical engineering decision. It directly dictates the coating's density, adhesion, hardness, and suitability for a given application, from a simple decorative finish to a high-performance, wear-resistant layer on a critical engine component.

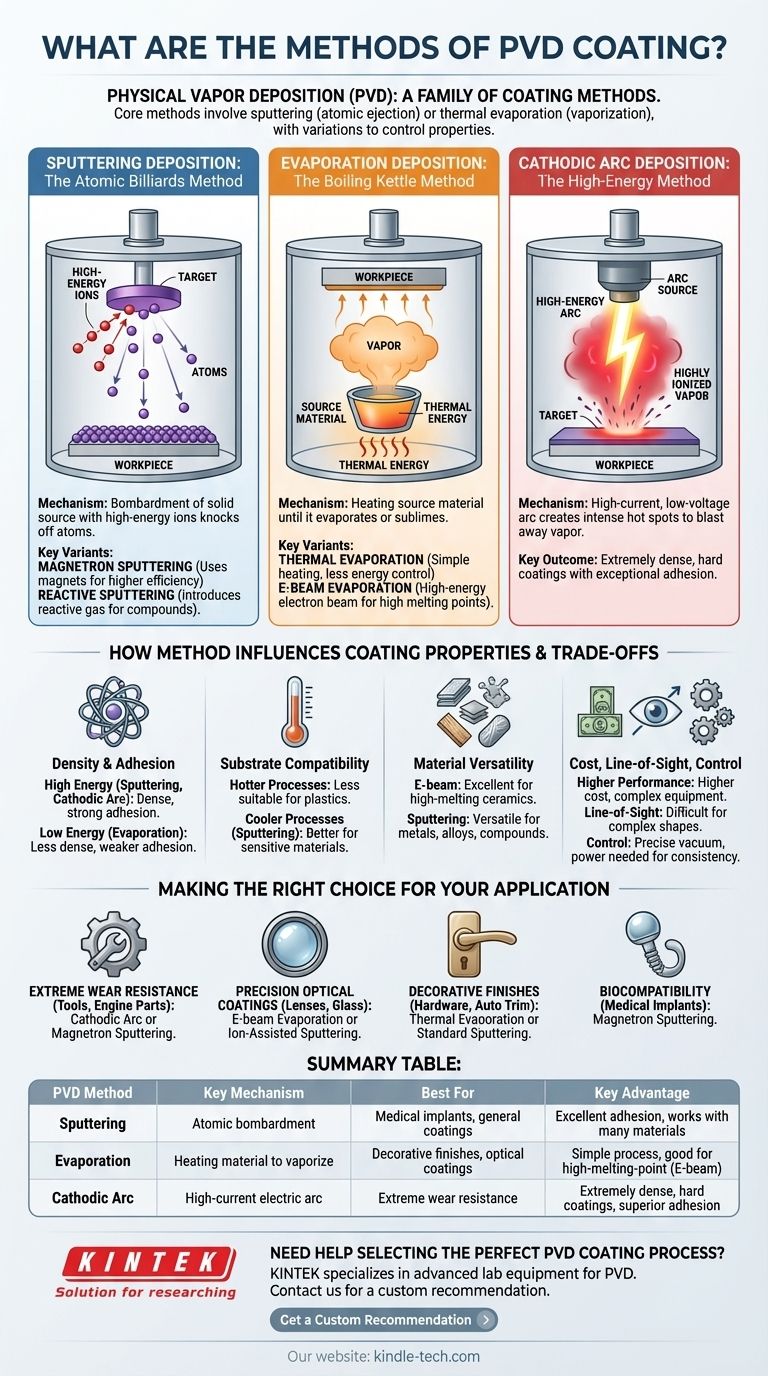

The Core PVD Processes Explained

To understand PVD, you must first understand the fundamental ways a solid material can be turned into a vapor inside a vacuum chamber. Each method offers a different level of energy, control, and efficiency.

Sputtering Deposition: The Atomic Billiards Method

Sputtering involves bombarding a solid source material, known as the target, with high-energy ions (typically from a gas like Argon).

This collision is like a high-speed billiard break at the atomic level, knocking atoms off the target's surface. These ejected atoms then travel through the vacuum chamber and deposit onto the workpiece, forming a thin, dense film.

Magnetron sputtering is the most common industrial variant. It uses powerful magnets behind the target to trap electrons, which dramatically increases the efficiency of the ion bombardment and allows for faster deposition rates at lower pressures.

Reactive sputtering is a technique where a reactive gas, like oxygen or nitrogen, is introduced into the chamber. This gas reacts with the sputtered atoms to form new compound coatings, such as titanium nitride (TiN) or aluminum oxide (Al₂O₃), directly on the substrate.

Evaporation Deposition: The Boiling Kettle Method

Evaporation is the conceptually simplest PVD method. The source material is heated in a vacuum until it evaporates or sublimes, turning into a vapor that then condenses on the cooler workpiece.

Thermal evaporation is the most basic form, where the material is heated by passing a current through a resistive boat or filament containing the source material. It is effective but offers less control over the energy of the vaporized atoms.

Electron-beam (E-beam) evaporation provides more precise control. It uses a magnetically focused beam of high-energy electrons to heat the source material. This allows for the evaporation of materials with very high melting points, such as titanium or ceramic oxides, which is critical for many optical and medical applications.

Cathodic Arc Deposition: The High-Energy Method

Cathodic Arc Deposition, or Arc-PVD, is a high-energy process that uses a high-current, low-voltage electric arc to vaporize material from the target.

The arc creates a series of small, intensely hot spots that blast away highly ionized vapor. This high-energy plasma results in extremely dense and hard coatings with exceptional adhesion, making it ideal for demanding wear-resistant applications like cutting tools and engine components.

How Method Influences Coating Properties

The choice of method is not arbitrary; it's determined by the desired outcome. The energy imparted to the vaporized atoms is the key differentiator.

Coating Density and Adhesion

High-energy processes like sputtering and cathodic arc deposition produce coatings that are more dense and adhere more strongly to the substrate. The energetic atoms essentially embed themselves into the surface, creating a superior bond.

Lower-energy processes like thermal evaporation produce less dense films with weaker adhesion, which may be sufficient for decorative applications but not for high-wear environments.

Substrate Compatibility

Some processes are "hotter" than others. For temperature-sensitive substrates like plastics, a lower-temperature process like sputtering is often preferred over a method that generates more radiant heat.

Target Material Versatility

The method must be compatible with the source material. E-beam evaporation is excellent for ceramics and materials with high melting points, while sputtering can be used with a vast range of metals, alloys, and compounds.

Understanding the Trade-offs

Every engineering decision involves balancing competing factors. PVD is no different.

Cost vs. Performance

Generally, higher-performance coatings require more complex and expensive equipment. Thermal evaporation systems are relatively simple, while magnetron sputtering and cathodic arc systems represent a significant capital investment.

Line-of-Sight Limitation

A fundamental characteristic of all PVD methods is that they are line-of-sight processes. The coating material travels in a straight line from the source to the substrate. This makes it challenging to evenly coat complex, three-dimensional shapes without sophisticated rotating fixtures.

Process Control and Repeatability

Achieving a specific color, hardness, or thickness requires precise control over vacuum levels, gas flow, power, and temperature. More advanced methods like reactive sputtering demand highly sophisticated process controls to ensure consistent, repeatable results batch after batch.

Making the Right Choice for Your Application

Your final decision should be driven by the primary requirement of your component.

- If your primary focus is extreme wear resistance (tools, engine parts): Cathodic arc deposition or magnetron sputtering are the ideal choices for their hard, dense, and highly adherent coatings.

- If your primary focus is precision optical coatings (lenses, glass): E-beam evaporation and ion-assisted sputtering provide the high level of control needed to create specific refractive indices and anti-reflection layers.

- If your primary focus is decorative finishes (home hardware, auto trim): Thermal evaporation or standard sputtering can provide excellent aesthetic results with good corrosion resistance at a lower cost.

- If your primary focus is biocompatibility (medical implants): Magnetron sputtering is a proven method for depositing inert, dense layers of materials like titanium nitride that prevent leaching and improve wear.

Ultimately, understanding the core mechanisms of each PVD method empowers you to select the process that best aligns with your material, performance, and economic goals.

Summary Table:

| PVD Method | Key Mechanism | Best For | Key Advantage |

|---|---|---|---|

| Sputtering | Atomic bombardment of target | Medical implants, general coatings | Excellent adhesion, works with many materials |

| Evaporation | Heating material to vaporize | Decorative finishes, optical coatings | Simple process, good for high-melting-point materials (E-beam) |

| Cathodic Arc | High-current electric arc | Extreme wear resistance (tools, engine parts) | Extremely dense, hard coatings with superior adhesion |

Need help selecting the perfect PVD coating process for your laboratory or manufacturing needs?

KINTEK specializes in providing advanced lab equipment and consumables for PVD coating applications. Our experts can help you choose the right solution to achieve the specific coating properties—like hardness, adhesion, or biocompatibility—that your project demands.

Contact us today using the form below to discuss how our PVD solutions can enhance your product's performance and durability.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Evaporation Boat for Organic Matter

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

People Also Ask

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition