At its core, the synthesis of high-quality, large-area graphene for practical applications is dominated by a method known as Chemical Vapor Deposition (CVD). This "bottom-up" technique allows for the controlled growth of single or few-layer graphene sheets on a catalytic metal substrate, which can then be transferred for use in electronics and other advanced materials.

The central challenge in graphene synthesis isn't just creating the material, but producing it at scale with consistent, high quality. CVD has become the leading method because it uniquely addresses this challenge, enabling the growth of large, uniform films suitable for commercial and research applications.

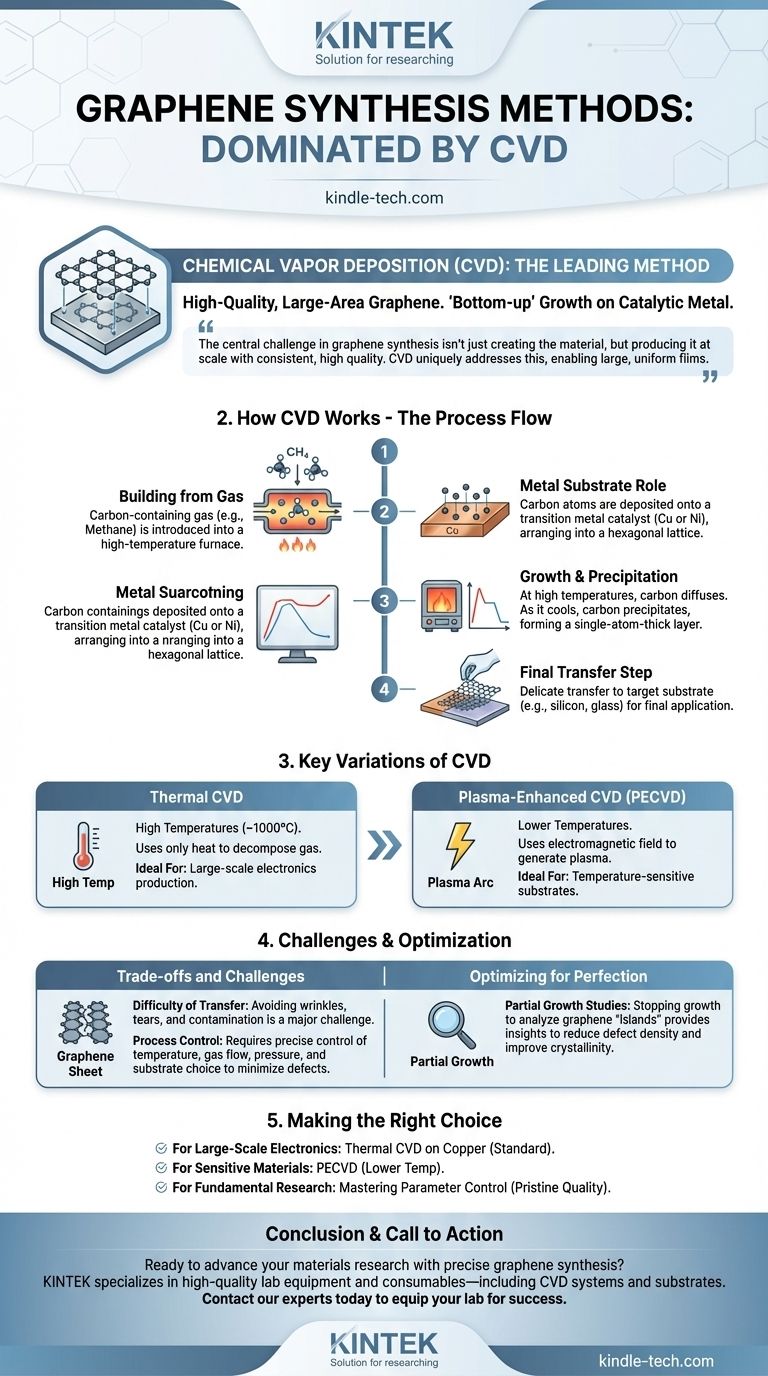

How Chemical Vapor Deposition (CVD) Works

CVD is a process that builds a material atom by atom from a gaseous state onto a solid surface. For graphene, this involves using a carbon-based gas and a metal catalyst.

The Core Principle: Building from Gas

The process begins by introducing a carbon-containing gas, most commonly methane (CH₄), into a high-temperature furnace. The heat breaks the gas molecules down, freeing individual carbon atoms.

The Role of the Metal Substrate

These free carbon atoms are deposited onto a substrate, typically a foil made of a transition metal like copper (Cu) or nickel (Ni). This metal foil acts as a catalyst, providing a surface where the carbon atoms can arrange themselves into the hexagonal lattice structure of graphene.

The Growth and Precipitation Process

At high temperatures, carbon atoms diffuse into or onto the surface of the metal. As the system is cooled, the solubility of carbon in the metal decreases, forcing the carbon atoms to precipitate out and form a continuous, single-atom-thick layer of graphene on the foil's surface.

The Final Transfer Step

Once the graphene film has formed on the metal, it must be carefully transferred to a target substrate (like silicon or glass) for its final application. This delicate step is one of the most critical parts of the overall process.

Key Variations of the CVD Method

While the principle remains the same, there are two primary types of CVD used for graphene synthesis, differing mainly in how they supply the energy for the chemical reaction.

Thermal CVD

This is the most common approach. It relies purely on high temperatures (often around 1000°C) to decompose the carbon source gas and drive the deposition process.

Plasma-Enhanced CVD (PECVD)

This method uses an electromagnetic field to generate plasma, an ionized gas. The highly reactive plasma facilitates the chemical reactions at much lower temperatures, which can be an advantage when working with temperature-sensitive materials.

Understanding the Trade-offs and Challenges

While CVD is the most promising method for scalable graphene production, it is not without its complexities and limitations.

The Difficulty of Transfer

Moving a one-atom-thick sheet of material from the metal growth foil to a final substrate without introducing wrinkles, tears, or contamination is a significant engineering challenge. The quality of this transfer step can ultimately define the performance of the final device.

Process Control is Critical

The final quality of the graphene is highly sensitive to the synthesis parameters. Factors like temperature, gas flow rate, pressure, and the choice of metal substrate must be precisely controlled to minimize defects and achieve the desired number of graphene layers.

Optimizing for Perfection

Researchers use techniques like partial growth studies to perfect the process. By stopping the growth before a full sheet is formed, they can analyze how individual graphene "islands" nucleate and merge, providing insights needed to reduce defect density and improve crystallinity.

Making the Right Choice for Your Goal

Understanding the nuances of graphene synthesis is key to applying it effectively.

- If your primary focus is large-scale production for electronics: Thermal CVD on copper foil is the established industry standard, providing the best balance of quality and large-area uniformity.

- If your primary focus is integrating graphene with temperature-sensitive materials: Plasma-Enhanced CVD (PECVD) is the superior choice, as its lower operating temperatures prevent damage to the underlying substrate.

- If your primary focus is fundamental research on material quality: Mastering the control of CVD parameters through partial growth studies is essential for producing pristine, single-crystal graphene.

Ultimately, controlling the synthesis of graphene is the first and most critical step in harnessing its extraordinary properties for future technology.

Summary Table:

| Method | Key Feature | Ideal For |

|---|---|---|

| Thermal CVD | High-temperature growth (~1000°C) | Large-scale electronics production |

| Plasma-Enhanced CVD (PECVD) | Lower-temperature growth using plasma | Temperature-sensitive substrates |

Ready to advance your materials research with precise graphene synthesis? KINTEK specializes in providing the high-quality lab equipment and consumables—including CVD systems and substrates—that researchers and engineers rely on to produce superior graphene. Our expertise supports your work from development to scalable production. Contact our experts today to discuss how we can equip your lab for success.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What does CVD method in carbon nanotubes synthesis stand for? Mastering Controlled Nanotube Growth

- What is sputtering method of thin film deposition? A Guide to Precision Coating

- What is the role of transition metal substrates in CVD graphene? Master Catalyst & Growth Mechanism Explained

- What is the difference between CVD and sputtering? Choose the Right Thin-Film Deposition Method

- What are the advantages and disadvantages of chemical Vapour deposition? A Guide to High-Performance Coatings

- What is the process of CVD? A Step-by-Step Guide to Chemical Vapor Deposition

- What is the difference between thin film and thick film coating? Precision vs. Durability Explained

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods