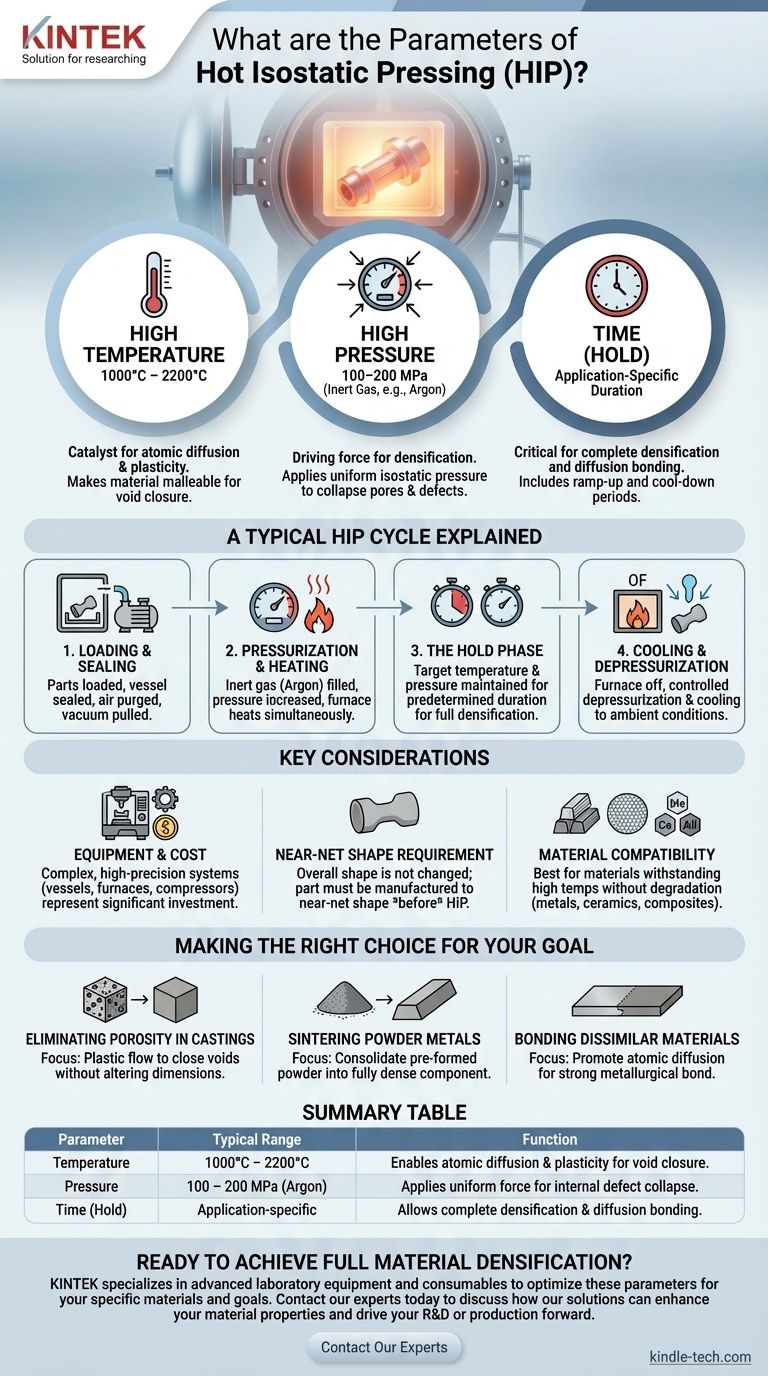

At its core, hot isostatic pressing (HIP) is defined by three primary parameters: high temperature, high pressure, and the duration of the process cycle. This advanced manufacturing technique applies uniform pressure in all directions to a component, typically ranging from 100 to 200 MPa, while simultaneously heating it in a furnace to temperatures between 1000°C and 2200°C. An inert gas, such as argon, is used as the medium to transfer this pressure evenly, ensuring the part is densified or bonded without changing its overall shape.

The critical insight is that hot isostatic pressing is not just about applying heat and pressure, but about the precise, simultaneous control of these parameters within a controlled atmosphere to achieve full material densification, eliminate internal defects, or create a metallurgical bond between materials.

The Core Parameters of the HIP Process

To understand hot isostatic pressing, you must understand the function of each controlled variable. The process takes place inside a specialized system consisting of a high-pressure vessel, an internal heating furnace, and sophisticated control systems.

High Temperature

Temperature is the catalyst for change at the microscopic level. By heating the material to a high temperature, typically below its melting point, you enable atomic diffusion and plastic deformation. This makes the material malleable enough for internal voids to collapse.

Isostatic Pressure

Pressure is the driving force for densification. An inert gas, almost always argon, is compressed to extremely high levels (100–200 MPa) inside the vessel. This gas applies a uniform, or isostatic, pressure from all directions onto the component, physically forcing internal pores, voids, and defects to close and weld shut.

Process Time

The third critical parameter is time. The component is held at the target temperature and pressure for a specific duration, known as the hold time. This period is essential to allow the material sufficient time to densify completely and for diffusion bonding to occur where necessary. The total cycle also includes controlled ramp-up and cool-down periods.

A Typical HIP Cycle Explained

The parameters of temperature, pressure, and time are not applied randomly. They are managed within a highly controlled, repeatable process cycle to ensure consistent results.

1. Loading and Sealing

First, the parts or components are loaded into the heating chamber, which is then sealed inside the main high-pressure vessel. The vessel is purged of air and a vacuum is pulled to remove any reactive gases like oxygen.

2. Pressurization and Heating

The vessel is filled with inert argon gas, and the pressure is increased using a compressor. Simultaneously, the internal furnace begins to heat the chamber and the components. These two parameters are raised in a controlled, synchronized manner.

3. The Hold Phase

Once the target temperature and pressure are reached, the system enters the hold phase. The control system maintains these parameters with high precision for the predetermined amount of time, allowing the material to achieve its final, fully dense state.

4. Cooling and Depressurization

After the hold phase is complete, the furnace is turned off and the vessel begins to cool. The gas pressure is slowly and safely released in a controlled depressurization phase. Once at ambient conditions, the components can be safely removed.

Understanding the Key Considerations

While powerful, the HIP process involves specific constraints and trade-offs that are important to understand.

Equipment and Cost

HIP systems are highly complex and precise pieces of equipment. They consist of a heavy-walled pressure vessel, a high-temperature furnace, gas compressors, vacuum pumps, and advanced control systems. This complexity makes the process a significant investment.

Near-Net Shape Requirement

The isostatic nature of the pressure ensures that a component's overall shape is not changed. This means the part must be manufactured to its near-net shape before the HIP cycle. HIP is a densification or bonding process, not a forming process.

Material Compatibility

The process is best suited for materials that can withstand high temperatures without degrading. This includes most metals, alloys, ceramics, and certain composite materials. The specific temperature and pressure parameters must be carefully selected based on the material being processed.

Making the Right Choice for Your Goal

The exact parameters for a HIP cycle are chosen based on the material and the desired outcome.

- If your primary focus is eliminating porosity in castings: The key is to select a temperature and pressure sufficient to cause plastic flow and close internal voids without altering the part's critical dimensions.

- If your primary focus is sintering powder metals: The parameters must be precisely controlled to consolidate a pre-formed powder shape into a fully dense, solid component with optimal mechanical properties.

- If your primary focus is bonding dissimilar materials: The cycle must be carefully engineered to promote atomic diffusion across the interface of the two materials, creating a true metallurgical bond stronger than the parent materials.

Ultimately, mastering the interplay of temperature, pressure, and time is the key to unlocking the full potential of hot isostatic pressing for your application.

Summary Table:

| Parameter | Typical Range | Function |

|---|---|---|

| Temperature | 1000°C – 2200°C | Enables atomic diffusion and material plasticity for void closure. |

| Pressure | 100 – 200 MPa (Argon) | Applies uniform force from all directions to collapse internal defects. |

| Time (Hold) | Application-specific | Allows complete densification and diffusion bonding to occur. |

Ready to achieve full material densification and eliminate internal defects?

The precise control of temperature, pressure, and time is critical for a successful Hot Isostatic Pressing (HIP) cycle. KINTEK specializes in advanced laboratory equipment and consumables, providing the technology and expertise to optimize these parameters for your specific materials and goals—whether you're working with castings, powdered metals, or advanced composites.

Contact our experts today to discuss how our solutions can enhance your material properties and drive your R&D or production forward.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is HIP treatment for metal? Eliminate Internal Defects for Superior Part Performance

- What pressure is hot isostatic press? Achieve Full Density & Superior Material Performance

- How much energy does hot isostatic pressing consume? Unlock Net Energy Savings in Your Process

- What are the components of a hot isostatic pressing system? A Guide to Core HIP Equipment

- Is hot isostatic pressing a heat treatment? A Guide to Its Unique Thermomechanical Process