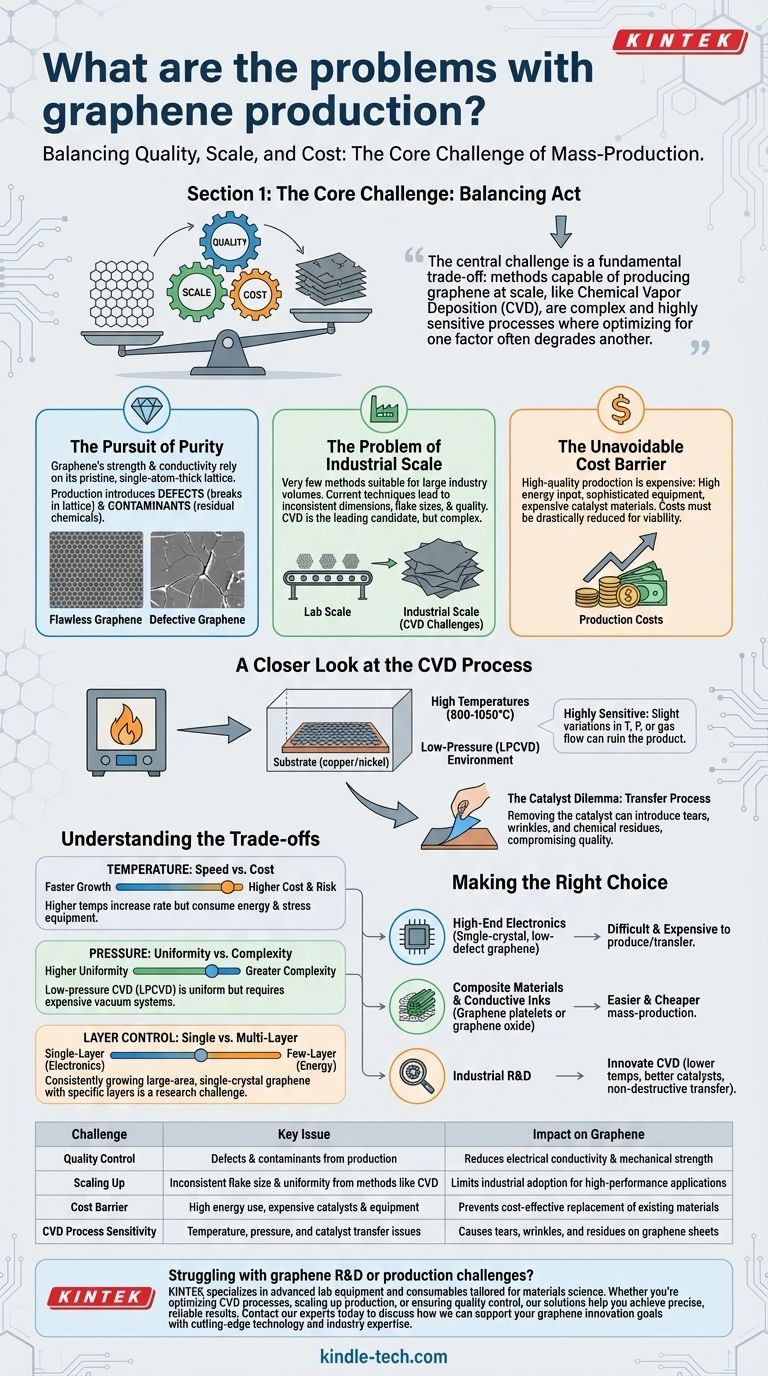

At its core, the primary obstacle to the widespread use of graphene is the immense difficulty in mass-producing a high-quality material at a low cost. While lab-scale methods can create nearly perfect graphene, the existing processes for industrial-scale production struggle to consistently achieve the required purity, structural integrity, and economic viability.

The central challenge is a fundamental trade-off: methods capable of producing graphene at scale, like Chemical Vapor Deposition (CVD), are complex and highly sensitive processes where optimizing for one factor—such as speed or volume—often degrades another, like quality or cost.

The Core Challenge: Balancing Quality, Scale, and Cost

The promise of graphene rests on its flawless atomic structure. Any deviation from this perfection degrades its remarkable properties. The production challenge is a constant balancing act between three competing factors.

The Pursuit of Purity and Perfection

Graphene's strength and conductivity are tied to its pristine, single-atom-thick lattice. Production methods, however, can introduce defects and contaminants.

These imperfections, such as breaks in the lattice or residual chemicals from the manufacturing process, act as roadblocks for electrons and weak points in the material's structure, significantly diminishing its performance.

The Problem of Industrial Scale

While many methods can produce small amounts of graphene, very few are suitable for the large volumes required by industry.

Current techniques often result in material with inconsistent dimensions, flake sizes, and quality levels. Chemical Vapor Deposition (CVD) is the leading candidate for scale, but it is far from a simple "plug-and-play" solution.

The Unavoidable Cost Barrier

High-quality graphene production is an expensive endeavor. The processes demand high energy input, sophisticated equipment, and often rely on expensive catalyst materials.

These costs must be drastically reduced for graphene to become a viable replacement for materials like silicon in electronics or a common additive in composites.

A Closer Look at the CVD Process

Chemical Vapor Deposition is the most promising method for producing large, continuous sheets of graphene, but it is exceptionally delicate and fraught with technical hurdles.

A Highly Sensitive Environment

The CVD process involves flowing hydrocarbon gases over a catalyst substrate at extremely high temperatures, typically between 800°C and 1050°C.

Controlling this environment is paramount. Most systems use low-pressure chambers (LPCVD) to prevent unwanted gas-phase reactions and ensure the graphene layer deposits with a uniform thickness. Even slight variations in temperature, pressure, or gas flow can ruin the final product.

The Catalyst Dilemma

CVD requires a catalyst, typically a metal like copper or nickel, for the graphene to form on. After growth, this catalyst layer must be removed.

This transfer process is a major source of potential problems. Etching away the metal can introduce tears, wrinkles, and chemical residues onto the fragile graphene sheet, compromising the very quality the CVD process was meant to achieve.

Understanding the Trade-offs

Every decision in the graphene production process involves a compromise, and understanding these is key to appreciating the overall challenge.

Temperature: Speed vs. Cost

Higher temperatures generally increase the reaction rate, allowing for faster graphene growth.

However, operating at over 1000°C consumes massive amounts of energy and places extreme stress on the equipment, increasing both operational costs and the risk of system failure.

Pressure: Uniformity vs. Complexity

Low-pressure CVD is favored for producing highly uniform, single-layer graphene, which is critical for electronics.

This, however, requires complex and expensive vacuum chamber systems. Atmospheric-pressure CVD (APCVD) is simpler and cheaper but makes it much harder to control the growth uniformity.

Layer Control: Single vs. Multi-Layer

For many electronic applications, a perfect single layer of graphene is the goal. For others, like energy storage, precisely controlled few-layer graphene is ideal.

CVD has been optimized for growing large, single-layer sheets. Consistently growing large-area, single-crystal graphene with a specific number of layers remains a significant and unsolved research challenge.

Making the Right Choice for Your Goal

The "best" graphene production method depends entirely on the intended application, as different use cases can tolerate different levels of quality and cost.

- If your primary focus is high-end electronics: You must use single-crystal, low-defect graphene, which is currently the most difficult and expensive to produce and transfer without damage.

- If your primary focus is composite materials or conductive inks: You can likely use graphene platelets or graphene oxide, which have more defects but are far easier and cheaper to mass-produce via methods other than CVD.

- If your primary focus is industrial R&D: The goal is to innovate the CVD process by lowering temperatures, finding better catalysts, or developing a reliable, non-destructive transfer method.

Solving these fundamental production challenges is the final frontier separating graphene's theoretical promise from its real-world technological impact.

Summary Table:

| Challenge | Key Issue | Impact on Graphene |

|---|---|---|

| Quality Control | Defects & contaminants from production | Reduces electrical conductivity & mechanical strength |

| Scaling Up | Inconsistent flake size & uniformity from methods like CVD | Limits industrial adoption for high-performance applications |

| Cost Barrier | High energy use, expensive catalysts & equipment | Prevents cost-effective replacement of existing materials |

| CVD Process Sensitivity | Temperature, pressure, and catalyst transfer issues | Causes tears, wrinkles, and residues on graphene sheets |

Struggling with graphene R&D or production challenges? KINTEK specializes in advanced lab equipment and consumables tailored for materials science. Whether you're optimizing CVD processes, scaling up production, or ensuring quality control, our solutions help you achieve precise, reliable results. Contact our experts today to discuss how we can support your graphene innovation goals with cutting-edge technology and industry expertise.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

People Also Ask

- What are the three main stages of the chemical vapour deposition process? Master CVD for Superior Thin-Film Quality

- What is the high temperature for CVD? Unlock Optimal Film Quality for Your Lab

- What is the gas deposition technique? A Guide to PVD and CVD Thin-Film Methods

- What is chemical vapor deposition in a CVD furnace? A Guide to High-Purity Thin Film Growth

- What is Thermally Activated Chemical Vapor Deposition (TACVD)? High-Purity Coating for Heat-Resistant Materials

- What is thin film vapor deposition? A Guide to Precision Surface Engineering

- What are the advantages of Fluidized Bed Chemical Vapor Deposition (FB-CVD)? Scalable CNT Production

- What are precursors in CVD process? The Essential Ingredient for Thin-Film Success