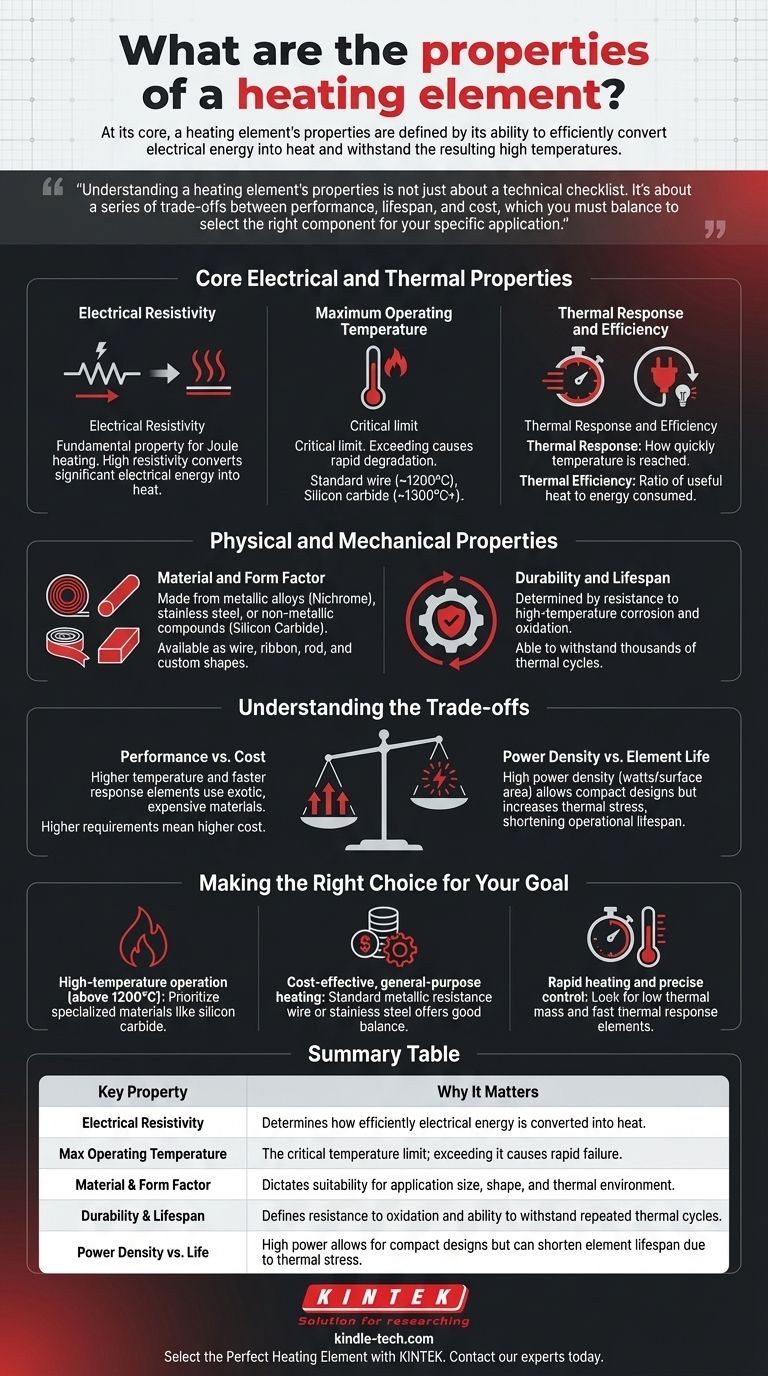

At its core, a heating element's properties are defined by its ability to efficiently convert electrical energy into heat and withstand the resulting high temperatures. The key characteristics are a material's electrical resistivity, its maximum operating temperature, its physical form, and its resistance to degradation over time.

Understanding a heating element's properties is not just about a technical checklist. It's about a series of trade-offs between performance, lifespan, and cost, which you must balance to select the right component for your specific application.

Core Electrical and Thermal Properties

The primary function of a heating element is governed by its electrical and thermal behavior. These properties determine how hot it can get, how quickly it heats up, and how efficiently it operates.

Electrical Resistivity

All heating elements work on the principle of Joule heating. When an electric current flows through a material with high electrical resistance, the electrical energy is converted into thermal energy, or heat.

Therefore, a high electrical resistivity is the most fundamental property of a heating element material. This allows it to generate significant heat without requiring excessively high currents.

Maximum Operating Temperature

The maximum operating temperature is a critical limit that dictates the element's suitability for an application. Exceeding this temperature will cause rapid degradation and failure.

Different materials have vastly different temperature capabilities. For example, standard resistance wires might be suitable for up to 1200°C, while materials like silicon carbide are required for higher temperatures around 1300°C and beyond.

Thermal Response and Efficiency

Thermal response refers to how quickly the element reaches its target temperature. Elements with low mass and high power density, like certain stainless steel designs, often have a very fast thermal response.

Thermal efficiency is the ratio of useful heat produced to the electrical energy consumed. High efficiency means less energy is wasted, leading to lower operating costs and better performance.

Physical and Mechanical Properties

Beyond its ability to generate heat, an element's physical form and durability are crucial for its integration and long-term reliability in a device.

Material and Form Factor

Heating elements are made from a range of materials, most commonly metallic alloys (like Nichrome or Kanthal), stainless steel, and non-metallic compounds (like silicon carbide or molybdenum disilicide).

They are available in various form factors, including wire, ribbon, or rod, and can often be bent into custom shapes. This adaptability allows them to be used in applications of nearly any size and geometry.

Durability and Lifespan

An element's lifespan is determined by its resistance to high-temperature corrosion and oxidation. A quality element must be able to cycle to its operating temperature thousands of times without failing.

Properties like high reliability and a long service life are direct results of choosing a material that is stable in the intended thermal environment.

Understanding the Trade-offs

Selecting a heating element is rarely about finding one with the "best" properties in every category. More often, it is about navigating a series of critical trade-offs.

Performance vs. Cost

This is the most common trade-off. Elements designed for higher temperatures or faster thermal response are engineered from more exotic and expensive materials.

As a rule, the higher the required operating temperature, the higher the cost of the element. You must align your choice with the actual temperature requirements to avoid overspending.

Power Density vs. Element Life

Power density refers to how much heat (in watts) is generated per unit of surface area. While high power density allows for compact and powerful designs, it also puts more thermal stress on the element.

Pushing an element to its maximum power rating can shorten its operational lifespan. For applications requiring maximum reliability, it is often better to use a larger element or operate it slightly below its maximum rated power.

Making the Right Choice for Your Goal

Your final decision should be guided by the primary objective of your heating application.

- If your primary focus is high-temperature operation (above 1200°C): Prioritize elements made from specialized materials like silicon carbide, as standard resistance wires will not be suitable.

- If your primary focus is cost-effective, general-purpose heating: Standard metallic resistance wire or stainless steel elements offer a great balance of performance, long life, and low cost for moderate temperatures.

- If your primary focus is rapid heating and precise control: Look for elements with a low thermal mass and a reputation for fast thermal response.

By carefully balancing these properties, you can select a heating element that delivers reliable performance for its intended purpose.

Summary Table:

| Key Property | Why It Matters |

|---|---|

| Electrical Resistivity | Determines how efficiently electrical energy is converted into heat (Joule heating). |

| Max Operating Temperature | The critical temperature limit; exceeding it causes rapid failure. |

| Material & Form Factor | Dictates suitability for application size, shape, and thermal environment (e.g., wire, ribbon). |

| Durability & Lifespan | Defines resistance to oxidation and ability to withstand repeated thermal cycles. |

| Power Density vs. Life | High power allows for compact designs but can shorten element lifespan due to thermal stress. |

Select the Perfect Heating Element with KINTEK

Choosing the right heating element is critical to your project's success, balancing performance, longevity, and budget. The properties outlined above are the foundation of a reliable system.

KINTEK specializes in lab equipment and consumables, providing expert guidance and high-quality heating solutions tailored to your specific laboratory needs. Whether your priority is high-temperature operation, cost-effective general-purpose heating, or rapid thermal response, we have the expertise and product range to help.

Let us help you make the right choice. Contact our experts today to discuss your application requirements and find the optimal heating element for your goals.

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Automatic Laboratory Heat Press Machine

- Platinum Sheet Electrode for Laboratory and Industrial Applications

People Also Ask

- What is molybdenum highest melting point? 2622°C for Extreme Heat Applications

- What are the high resistance heating elements? Choose the Right Element for Your Temperature & Atmosphere

- What is the difference between induction and resistance heating? A Guide to Choosing the Right Heat Source

- What are heating elements with tungsten? Unlock Extreme Heat for Vacuum & Industrial Processes

- Should heating element have high or low resistance? Unlock the Key to Efficient Heat Generation

- How do multiple cartridge heaters and K-type thermocouples work together? Achieve Optimal Temperature Uniformity

- What is an industrial heating element? Your Guide to Precision, Durability & High-Performance Heating

- How efficient is a quartz heating element? Unlock Up to 96% Radiant Efficiency for Targeted Heating