At their core, the choice between a mechanical and a hydraulic press comes down to how force is applied. Mechanical presses deliver a rapid, high-impact punch with extreme positional repeatability, making them ideal for speed. Hydraulic presses deliver a controlled, sustained force throughout the entire stroke, making them the choice for power and flexibility.

The decision is not about which press technology is superior overall, but about which force delivery profile—the fast, fixed stroke of a mechanical press or the slower, adaptable stroke of a hydraulic press—is the correct match for your specific metalworking application.

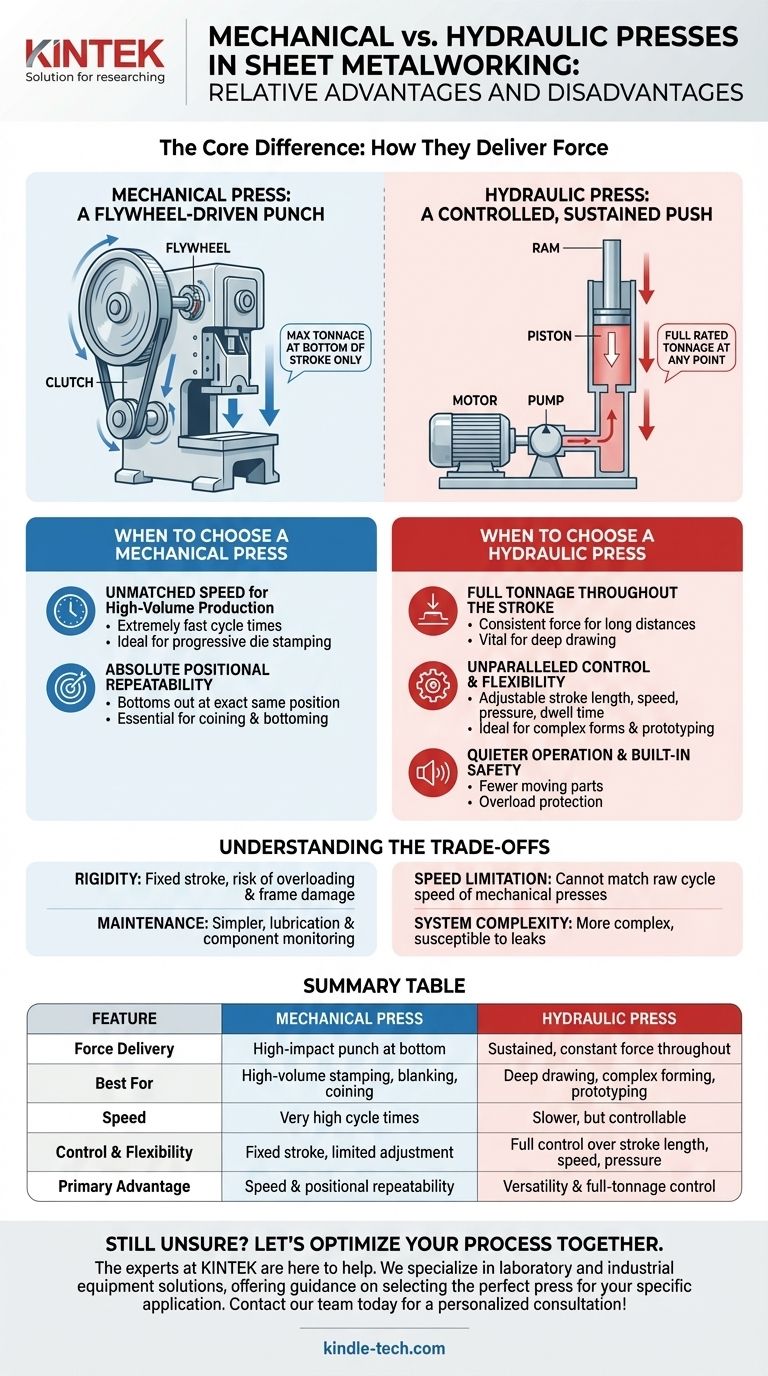

The Core Difference: How They Deliver Force

To understand the advantages of each press, you must first understand their fundamental mechanisms. Their entire performance profile stems from this difference.

The Mechanical Press: A Flywheel-Driven Punch

A mechanical press stores energy in a massive, spinning flywheel. When the press is activated, a clutch engages and connects the flywheel to a crankshaft, which drives the ram down in a single, rapid motion.

This design means maximum tonnage is only available at the very bottom of the stroke. The stroke length itself is fixed by the physical geometry of the crankshaft.

The Hydraulic Press: A Controlled, Sustained Push

A hydraulic press uses a motor-driven pump to force hydraulic fluid into a cylinder, which moves a piston to drive the ram down. This system is governed by Pascal's principle of fluid pressure.

This design allows the press to deliver its full rated tonnage at any point during its stroke, from the very top to the very bottom. Every aspect—stroke length, speed, and pressure—is controllable.

When to Choose a Mechanical Press

Mechanical presses are the workhorses of high-volume manufacturing where speed and consistency are the primary goals.

Unmatched Speed for High-Volume Production

The flywheel-driven mechanism allows for extremely fast cycle times. This makes mechanical presses the definitive choice for progressive die stamping and other high-volume operations where thousands of parts must be produced per hour.

Absolute Positional Repeatability

Because the stroke is determined by the fixed mechanics of a crankshaft, a mechanical press will bottom out at the exact same position on every single stroke. This precision is essential for applications like coining and bottoming, which require precise material compression.

When to Choose a Hydraulic Press

Hydraulic presses are valued for their versatility, power, and precise control over the entire forming process.

Full Tonnage Throughout the Stroke

This is the most significant advantage of a hydraulic press. For operations like deep drawing, where force must be applied consistently over a long distance, a hydraulic press is the only viable option.

Unparalleled Control and Flexibility

The operator has complete control over the ram. Stroke length, ram speed, pressure, and dwell time (the amount of time the press remains under pressure at the bottom of the stroke) can all be adjusted. This makes them ideal for complex forms, prototyping, and jobs requiring fine-tuning.

Quieter Operation and Built-in Safety

As noted in industrial applications, hydraulic presses have fewer high-speed moving parts, resulting in significantly quieter operation. They also feature inherent overload protection; a pressure relief valve prevents the press from exceeding its rated tonnage, protecting both the machine and the tooling.

Understanding the Trade-offs

Neither press is without its limitations. Understanding these trade-offs is critical to avoiding costly mistakes.

The Rigidity of Mechanical Presses

The primary strength of a mechanical press—its fixed stroke—is also its main weakness. There is very little room for adjustment, and accidentally attempting to exceed its capacity (overloading) can cause catastrophic frame damage.

The Speed Limitation of Hydraulic Presses

The trade-off for the control and power of a hydraulic press is speed. While modern hydraulics are efficient, they cannot match the raw cycle speed of a mechanical press for simple, high-volume stamping.

Maintenance and System Complexity

Mechanical presses are generally simpler to maintain, involving lubrication and monitoring of mechanical components. Hydraulic systems, while reliable, can be more complex to troubleshoot and are susceptible to leaks if not properly maintained.

Making the Right Choice for Your Application

Selecting the right press requires a clear understanding of your primary goal.

- If your primary focus is high-volume stamping, blanking, or coining: A mechanical press is the correct choice for its superior speed and positional accuracy.

- If your primary focus is deep drawing, forming complex shapes, or working with variable materials: A hydraulic press provides the necessary constant force and process control.

- If your primary focus is versatility for prototyping or short-run jobs: A hydraulic press offers the easy adjustability required to handle a wide range of applications.

Ultimately, matching the press's method of applying force to the specific demands of your job is the key to successful and efficient metalworking.

Summary Table:

| Feature | Mechanical Press | Hydraulic Press |

|---|---|---|

| Force Delivery | High-impact punch at bottom of stroke | Sustained, constant force throughout stroke |

| Best For | High-volume stamping, blanking, coining | Deep drawing, complex forming, prototyping |

| Speed | Very high cycle times | Slower, but controllable |

| Control & Flexibility | Fixed stroke, limited adjustment | Full control over stroke length, speed, and pressure |

| Primary Advantage | Speed and positional repeatability | Versatility and full-tonnage control |

Still unsure which press technology is right for your metalworking needs? The experts at KINTEK are here to help. We specialize in providing laboratory and industrial equipment solutions, including guidance on selecting the perfect press for your specific application—whether your priority is high-volume production speed or versatile, controlled force for complex forming. Let's optimize your process together. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual Lab Heat Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- What role does a laboratory hydraulic press play in all-solid-state battery fabrication? Enhancing Ion Conductivity

- What core conditions does a laboratory hydraulic press provide for solid-state electrolyte pellets? Enhance Density!

- Why is a laboratory hydraulic press required during the preparation of Ti3AlC2 precursor pellets?

- What is the function of a bench-top laboratory hydraulic press for XRF? Maximize Accuracy in Prosopis juliflora Analysis

- What is the hydraulic forging process? Master the Art of High-Strength Metal Forming