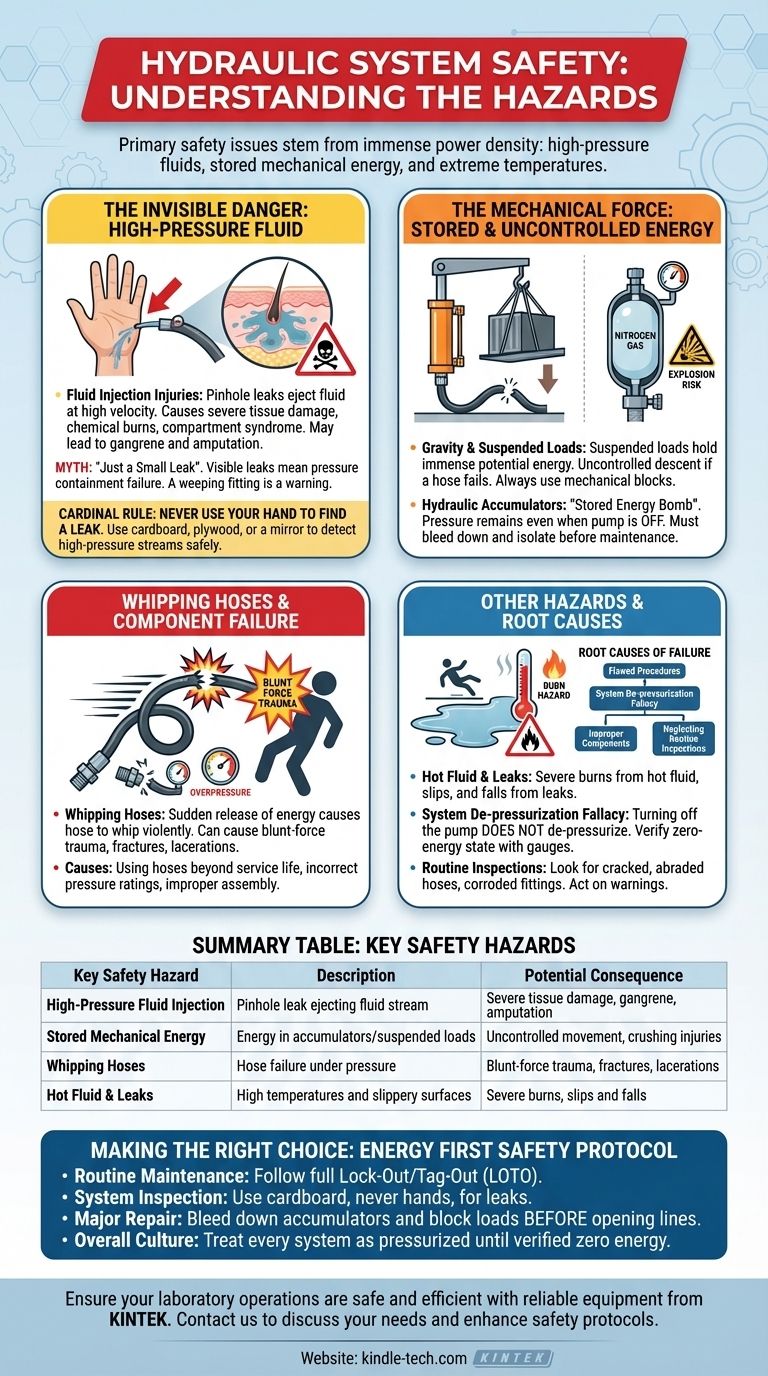

The primary safety issues with hydraulic systems stem from their immense power density, involving high-pressure fluids, stored mechanical energy, and extreme temperatures. The most severe risks include high-pressure fluid injection from pinhole leaks, which can cause catastrophic tissue damage, and crushing or shearing injuries from the uncontrolled release of stored energy. Additional hazards include severe burns from hot fluid, slips from leaks, and blunt-force trauma from whipping hoses during a failure.

The danger of hydraulics lies not just in the visible moving parts, but in the invisible, stored energy within the fluid itself. Treating a hydraulic system as "off" simply because the pump is not running is a critical and often catastrophic mistake.

The Invisible Danger: High-Pressure Fluid

The hydraulic fluid itself is a primary vector for severe injury. Its behavior under thousands of pounds per square inch (PSI) of pressure creates unique and often misunderstood hazards.

Understanding Fluid Injection Injuries

A fluid injection injury is the most insidious hydraulic hazard. It occurs when a pinhole leak, often invisible to the naked eye, ejects a stream of fluid at a velocity high enough to penetrate the skin.

This may initially feel like a bee sting or a simple puncture, but the fluid rapidly spreads through soft tissue, causing chemical burns, compressing blood vessels, and leading to compartment syndrome. Without immediate, specialized surgery, these injuries frequently result in gangrene and amputation.

The Myth of "Just a Small Leak"

Any visible leak, no matter how small, is an unambiguous sign that the system's pressure containment has failed. A weeping fitting or a damp hose is a critical warning that a catastrophic failure could be imminent.

Ignoring or downplaying these signs is a common precursor to accidents. The "small" leak can instantly become a high-velocity stream if the component fails further.

The Cardinal Rule: Never Use Your Hand to Find a Leak

Given the extreme danger of fluid injection, never use your hands or any body part to check for a hydraulic leak.

The correct and only safe method is to hold a piece of cardboard, plywood, or a mirror a safe distance from the suspected area. The fluid stream will mark the material, revealing the leak's location without endangering the operator.

The Mechanical Force: Stored and Uncontrolled Energy

Beyond the fluid, the mechanical energy that hydraulics control is a significant source of danger. This energy can be stored and released unexpectedly, even in a system that is turned off.

The Danger of Gravity and Suspended Loads

A hydraulic cylinder holding a heavy load (like a raised forklift mast or a press) is a reservoir of immense potential energy. If a hose fails or a valve malfunctions, this load can descend uncontrollably.

Any work performed under a hydraulically suspended load without proper mechanical blocking or supports is a grave risk. The hydraulic system alone should never be trusted to secure a raised load.

Hydraulic Accumulators: The Stored Energy Bomb

Accumulators are devices designed to store hydraulic fluid under pressure, often using a nitrogen gas bladder. Their purpose is to absorb shocks or provide an emergency source of power.

Crucially, an accumulator holds this pressure even when the main system pump is off. Failing to safely bleed down and isolate an accumulator before performing maintenance is like trying to defuse a bomb without knowing the procedure. The stored energy can discharge instantly when a line is opened.

Whipping Hoses and Component Failure

When a hydraulic hose or fitting fails under pressure, the sudden release of energy can cause the hose to whip around with incredible speed and force.

A whipping hose can cause severe blunt-force trauma, fractures, and lacerations to anyone in its path. This is often the result of using hoses beyond their service life or installing components with incorrect pressure ratings.

Understanding the Pitfalls: The Root Causes of Failure

Accidents are rarely spontaneous. They are typically the result of flawed procedures, a lack of understanding of the system's state, or the degradation of components over time.

The Fallacy of System De-pressurization

Simply turning off the electric motor or engine that powers the hydraulic pump does not de-pressurize the system.

Pressure can remain trapped in circuits due to check valves, pilot-operated valves, thermal expansion of the fluid, or within accumulators. A system is only at a zero-energy state when it has been properly locked out and all residual pressure has been safely bled from every part of the circuit, as verified by pressure gauges.

Improper Component Selection and Assembly

Using a hose with a lower pressure rating than the system requires, using mismatched fittings, or improperly torquing connections creates a built-in weak point. These components are destined to fail, turning a predictable situation into an emergency. Adherence to manufacturer specifications is not optional; it is a critical safety requirement.

Neglecting Routine Inspections

Hydraulic systems provide clear warnings before they fail. Hoses that are cracked, abraded, or blistering, along with corroded fittings and weeping seals, are all indicators of imminent failure. Performing and acting upon routine visual inspections is one of the most effective ways to prevent catastrophic incidents.

Making the Right Choice for Your Goal

Protecting yourself and your team requires a non-negotiable, multi-step safety protocol before any work begins. This always starts with thinking "energy first."

- If your primary focus is routine maintenance: Always follow a full Lock-Out/Tag-Out (LOTO) procedure, ensuring the system is de-energized and cannot be accidentally started.

- If your primary focus is system inspection: Never use your hands to check for leaks; use a piece of cardboard or wood to identify the source of a high-pressure spray from a safe distance.

- If your primary focus is major repair: Ensure all stored energy is released by safely bleeding down pressure from accumulators and lowering or mechanically blocking all suspended loads before opening any lines.

- If your primary focus is overall safety culture: Treat every hydraulic system as pressurized until you have personally verified it is at a zero energy state through gauges and proper bleed-down procedures.

Ultimately, hydraulic safety is achieved not by reacting to failures, but by proactively respecting the immense, stored energy present in every part of the system.

Summary Table:

| Key Safety Hazard | Description | Potential Consequence |

|---|---|---|

| High-Pressure Fluid Injection | Pinhole leak ejecting fluid stream | Severe tissue damage, gangrene, amputation |

| Stored Mechanical Energy | Energy in accumulators/suspended loads | Uncontrolled movement, crushing injuries |

| Whipping Hoses | Hose failure under pressure | Blunt-force trauma, fractures, lacerations |

| Hot Fluid & Leaks | High temperatures and slippery surfaces | Severe burns, slips and falls |

Ensure your laboratory operations are safe and efficient with reliable equipment from KINTEK. Hydraulic systems power many essential lab tools, from presses to lifts. Proper maintenance and understanding of their inherent risks are paramount to protecting your team and your research integrity. KINTEK specializes in providing high-quality lab equipment and consumables, backed by expert support to help you maintain a safe working environment. Contact us today via our [#ContactForm] to discuss your laboratory needs and how our solutions can enhance your safety protocols and operational efficiency.

Visual Guide

Related Products

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual Lab Heat Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Variable Speed Peristaltic Pump

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

People Also Ask

- What is a hydraulic hot press? Unlock the Power of Heat and Pressure for Advanced Materials

- Does a hydraulic press have heat? How Heated Platens Unlock Advanced Molding and Curing

- What is the purpose of using a laboratory hydraulic press for LGVO synthesis? Achieve High-Purity Solid Electrolytes

- What is a hydraulic hot press machine? A Guide to Force and Heat for Material Transformation

- What is a hot hydraulic press? Harness Heat and Pressure for Advanced Manufacturing