The cardinal rule for any experiment involving heat is to treat every surface as if it is hot until you can personally verify it is safe to touch. This principle is the foundation for a suite of precautions that include wearing appropriate Personal Protective Equipment (PPE), maintaining a clear and organized workspace, and understanding the specific behavior of the equipment and materials you are using. Safety is not a checklist, but a constant state of awareness.

Heat is an invisible hazard. Unlike a sharp object or a colored chemical, a dangerously hot surface often looks identical to a cool one. True laboratory safety comes from developing a mindset of deliberate action and respect for the energy you are handling, not just following a list of rules.

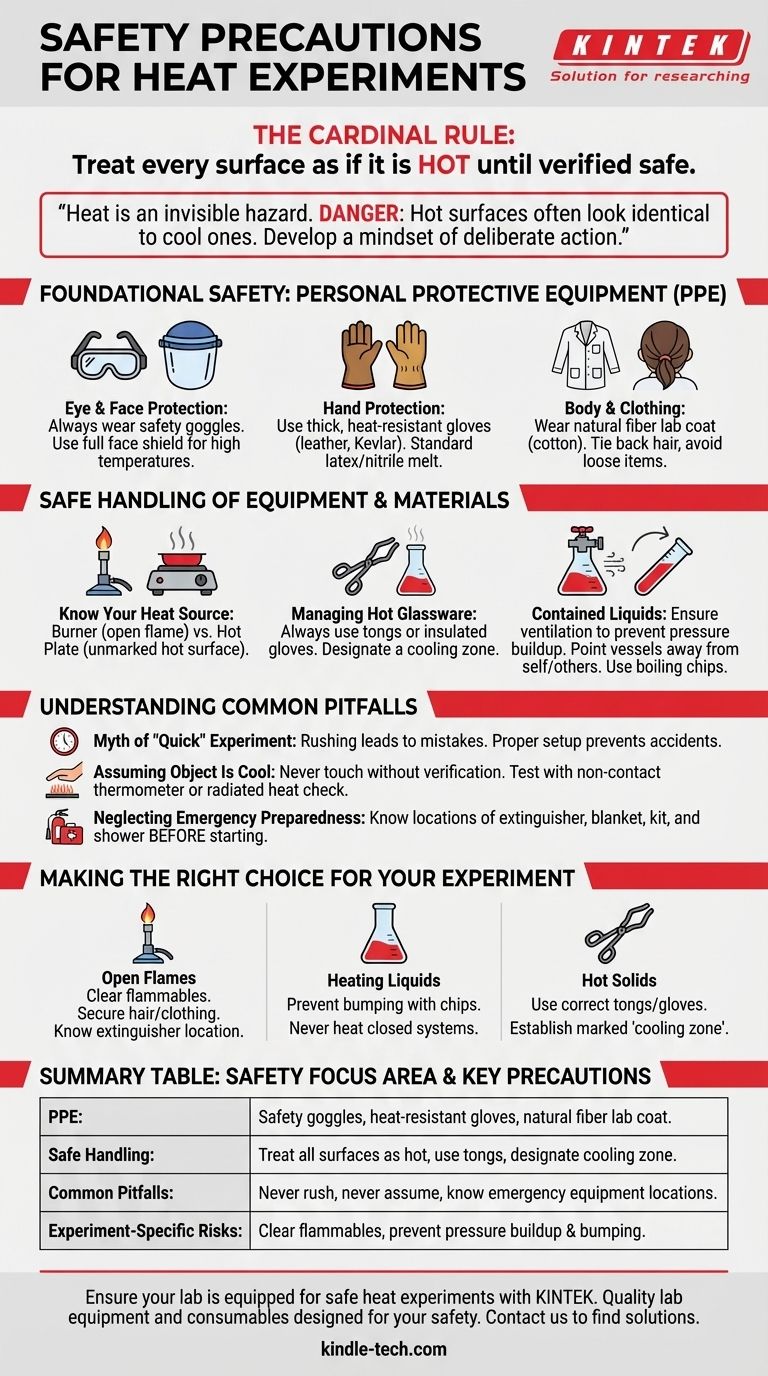

Foundational Safety: Personal Protective Equipment (PPE)

Your first line of defense is what you wear. Standard lab attire is often insufficient for heat-related work; you must select PPE specifically designed for thermal hazards.

Eye and Face Protection

You must always wear safety goggles to protect your eyes from splashes of hot liquids or unexpected shrapnel from fractured glassware. For high-temperature work, a full face shield worn over goggles is recommended.

Hand Protection

Standard latex or nitrile gloves offer no protection from heat and can melt onto your skin, causing severe burns. You must use thick, heat-resistant gloves (often made of leather, Kevlar, or other insulating materials) when handling hot objects.

Body and Clothing

Wear a lab coat made of natural fibers like cotton, as synthetic materials like polyester can melt and fuse to your skin. Always ensure long hair is tied back, and avoid wearing loose, dangling clothing or jewelry that could catch fire or knock over equipment.

Safe Handling of Equipment and Materials

How you interact with your experiment is as important as how you protect yourself. Mishandling hot equipment is a primary cause of lab accidents.

Know Your Heat Source

Different tools have different risks. A Bunsen burner provides an open flame, requiring extreme caution with flammable materials, while a hot plate has a large, unmarked hot surface that can be easily forgotten. Heating mantles provide even heating for round-bottom flasks but can hide the true temperature of the glass.

Managing Hot Glassware

Glass retains heat for a surprisingly long time and looks the same whether it is hot or cold. Always use tongs or insulated gloves to move hot glassware. Designate a specific, marked area on your bench for hot items to cool down.

The Danger of Contained Liquids

Heating liquids in an unvented or sealed container can cause a dramatic and dangerous pressure buildup, leading to an explosion. Always ensure the container is open or has a pressure-release path.

When heating liquids in test tubes or beakers, they can "bump" or boil over suddenly. Point the mouth of the vessel away from yourself and others at all times. Using boiling chips can help ensure a smoother, more controlled boil.

Understanding Common Pitfalls

Trusting assumptions is the most common path to injury in a lab. Being aware of these mental traps is a critical safety skill.

The Myth of the "Quick" Experiment

Rushing leads to mistakes. Taking a moment to set up a proper cooling area or find the correct tongs is always faster than dealing with a burn or a fire.

Assuming an Object Is Cool

This is the single most frequent cause of burns in a laboratory setting. Never touch a piece of equipment that has been part of a heat experiment without verifying its temperature first, either with a non-contact thermometer or by carefully bringing the back of your hand close to it to feel for radiated heat.

Neglecting Emergency Preparedness

Before you light a flame or turn on a hot plate, you must know the precise location of the fire extinguisher, fire blanket, first aid kit, and emergency shower. Precious seconds are lost when you have to search for safety equipment during an actual emergency.

Making the Right Choice for Your Experiment

Your safety focus should adapt to the specifics of your task. Use these principles to guide your setup.

- If your primary focus is working with open flames: Your priority is to clear the area of all flammable materials, secure your hair and clothing, and know the location of the fire extinguisher.

- If your primary focus is heating liquids in glassware: Your priority is preventing "bumping" by using boiling chips and ensuring you never heat a closed system that could build pressure.

- If your primary focus is handling hot solid objects: Your priority is to use the correct thermal tongs or gloves and to establish a clearly marked, dedicated "cooling zone" on your bench.

Ultimately, proactive planning is the most effective safety tool you have.

Summary Table:

| Safety Focus Area | Key Precautions |

|---|---|

| Personal Protective Equipment (PPE) | Safety goggles, heat-resistant gloves, natural fiber lab coat. |

| Safe Handling | Treat all surfaces as hot, use tongs/gloves, designate a cooling zone. |

| Common Pitfalls | Never rush, never assume an object is cool, know emergency equipment locations. |

| Experiment-Specific Risks | Clear flammables for open flames; prevent pressure buildup & bumping for liquids. |

Ensure your lab is equipped for safe heat experiments. KINTEK specializes in high-quality, safe lab equipment and consumables, from heat-resistant gloves to reliable hot plates. Our products are designed with your safety in mind, helping you prevent accidents and maintain a secure working environment. Contact us today to find the right safety solutions for your laboratory needs.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the highest temperature of a furnace? Unlocking the Limits of Extreme Heat

- What is the point of a muffle? Achieve Purity and Precision in High-Temperature Processes

- How does a muffle work? Achieve Clean, Contamination-Free Heating for Your Lab

- How do you make biochar in a muffle furnace? A Step-by-Step Guide to Controlled Pyrolysis

- What is a muffle furnace and how does it work? Achieve Clean, High-Temperature Heating for Your Lab