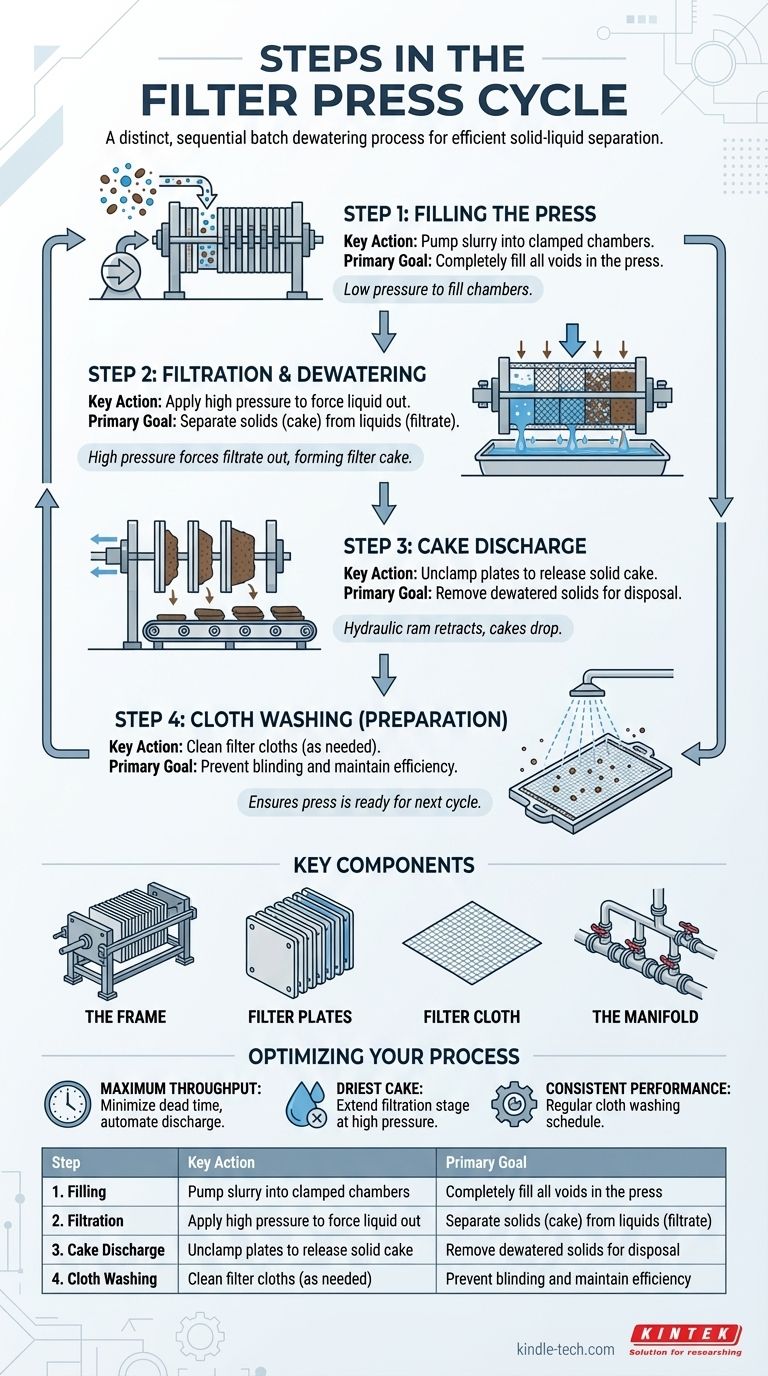

The filter press operates in a distinct, sequential cycle. This batch process consists of four main stages: filling the press with slurry, applying pressure to filter the liquid out, discharging the resulting solid cake, and preparing the press for the next cycle. Each step is critical for achieving efficient solid-liquid separation.

A filter press functions as a batch dewatering system. It uses high pressure to force a liquid (filtrate) through a filter medium, trapping the solid particles to form a compressed "filter cake" that is discharged at the end of each cycle.

Deconstructing the Filter Press Cycle

Understanding each stage of the cycle is essential for optimizing performance, whether your goal is maximum throughput, cake dryness, or filtrate clarity. The process is mechanical, reliable, and straightforward once broken down.

Step 1: Filling the Press

The cycle begins with the filter plates clamped tightly together by a hydraulic ram, creating a series of sealed chambers.

A feed pump then pushes the slurry (the mixture of solids and liquids) into these chambers through a manifold. This stage is typically done at a relatively low pressure, just enough to fill all the empty voids within the press completely.

Step 2: Filtration and Dewatering

Once the chambers are full, the filtration stage begins. The feed pump pressure is ramped up significantly.

This high pressure forces the liquid component of the slurry, known as the filtrate, to pass through the filter cloth on each side of the chamber. The solid particles are too large to pass through and are trapped on the cloth's surface.

As more filtrate is forced out, the retained solids build upon each other, forming a dense, dewatered filter cake. The pressure continues to rise as the cake becomes more compact and less permeable, until filtrate flow nearly stops.

Step 3: Cake Discharge

After the filtration stage is complete, the feed pump is shut off. The hydraulic ram retracts, unclamping and separating the filter plates.

This action allows the compacted, solid filter cakes to drop from between the plates, typically onto a conveyor or into a hopper below for collection and disposal. Some systems use shakers or other mechanisms to help dislodge stubborn cakes.

Step 4: Cloth Washing (Preparation for Next Cycle)

This final stage, sometimes called cloth conditioning, ensures the press is ready for the next batch. It is not always required after every single cycle but is a critical part of the overall operation.

The filter cloths may be sprayed with water to dislodge any fine particles that could clog the cloth's pores (a condition known as "blinding"). A clean cloth is vital for maintaining high filtration efficiency and consistent cycle times.

Understanding Key Components

The operational cycle is made possible by four primary components working in unison.

The Frame

This is the heavy-duty steel structure that holds the filter plates in alignment and endures the immense pressure generated during the filtration stage.

The Filter Plates

These plates, typically made of polypropylene, form the series of chambers that hold the slurry. Their design includes drainage surfaces that allow the filtrate to exit the press once it passes through the cloth.

The Filter Cloth

This is the critical separation medium. The cloth is tailored to the specific application, with its weave and material chosen to capture the solid particles while allowing clean liquid to pass through.

The Manifold

This system of pipes and valves controls the flow of slurry into the press and the exit of the filtrate. It ensures that each chamber fills and dewaters evenly.

Making the Right Choice for Your Goal

By understanding these steps, you can adjust the process to meet specific operational targets.

- If your primary focus is maximum throughput: Concentrate on minimizing the "dead time" of the cycle by automating cake discharge and ensuring fast, efficient filling.

- If your primary focus is achieving the driest possible cake: You must extend the filtration stage, holding the slurry under high pressure for a longer duration to squeeze out as much liquid as possible.

- If your primary focus is maintaining consistent performance: Implement a strict and regular cloth washing schedule to prevent blinding and ensure reliable filtration rates from one cycle to the next.

Mastering the filter press cycle gives you direct control over the efficiency and outcome of your solid-liquid separation process.

Summary Table:

| Step | Key Action | Primary Goal |

|---|---|---|

| 1. Filling | Pump slurry into clamped chambers | Completely fill all voids in the press |

| 2. Filtration | Apply high pressure to force liquid out | Separate solids (cake) from liquids (filtrate) |

| 3. Cake Discharge | Unclamp plates to release solid cake | Remove dewatered solids for disposal |

| 4. Cloth Washing | Clean filter cloths (as needed) | Prevent blinding and maintain efficiency |

Ready to optimize your dewatering process? KINTEK specializes in high-performance lab equipment and consumables, including filtration solutions. Our experts can help you select the right filter press or components to maximize your lab's throughput, achieve drier cakes, and ensure consistent results. Contact our team today to discuss your specific laboratory needs!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- Why is hydraulic pressure important? Harnessing Immense Force with Simple Systems

- What are the uses of hydraulic press in everyday life? The Invisible Force Shaping Your World

- What happens to hydraulic oil when hot? Prevent Viscosity Breakdown and Costly Oxidation

- What is the function of a laboratory hydraulic press in Diamond/Ti composite preparation? Ensuring Atomic Bonding

- What are the negative effects of heat in a hydraulic system? Prevent Costly Damage and Downtime

- What is the unit of pressure in a hydraulic press? Understanding PSI, Tons, and Force

- What is the function of laboratory hydraulic presses in leaching residue prep? Master SEM Sample Precision

- What is the potential application of a laboratory hydraulic press in zirconium hydrometallurgy? Bridge Your Research