At its core, Physical Vapor Deposition (PVD) is a vacuum-based process that transforms a solid coating material into a vapor, transports it atom by atom onto a substrate, and then condenses it back into a high-performance solid film. While specific techniques vary, every PVD process follows three fundamental stages: Vaporization, Transportation, and Deposition. A fourth optional step, Reaction, is often included to create specific compound coatings like nitrides or oxides.

PVD is best understood not as a single procedure, but as a framework for atomic-level construction. By controlling the transformation of a solid material into a vapor and back again within a vacuum, PVD enables the creation of exceptionally pure, dense, and durable thin-film coatings that are physically bonded to a surface.

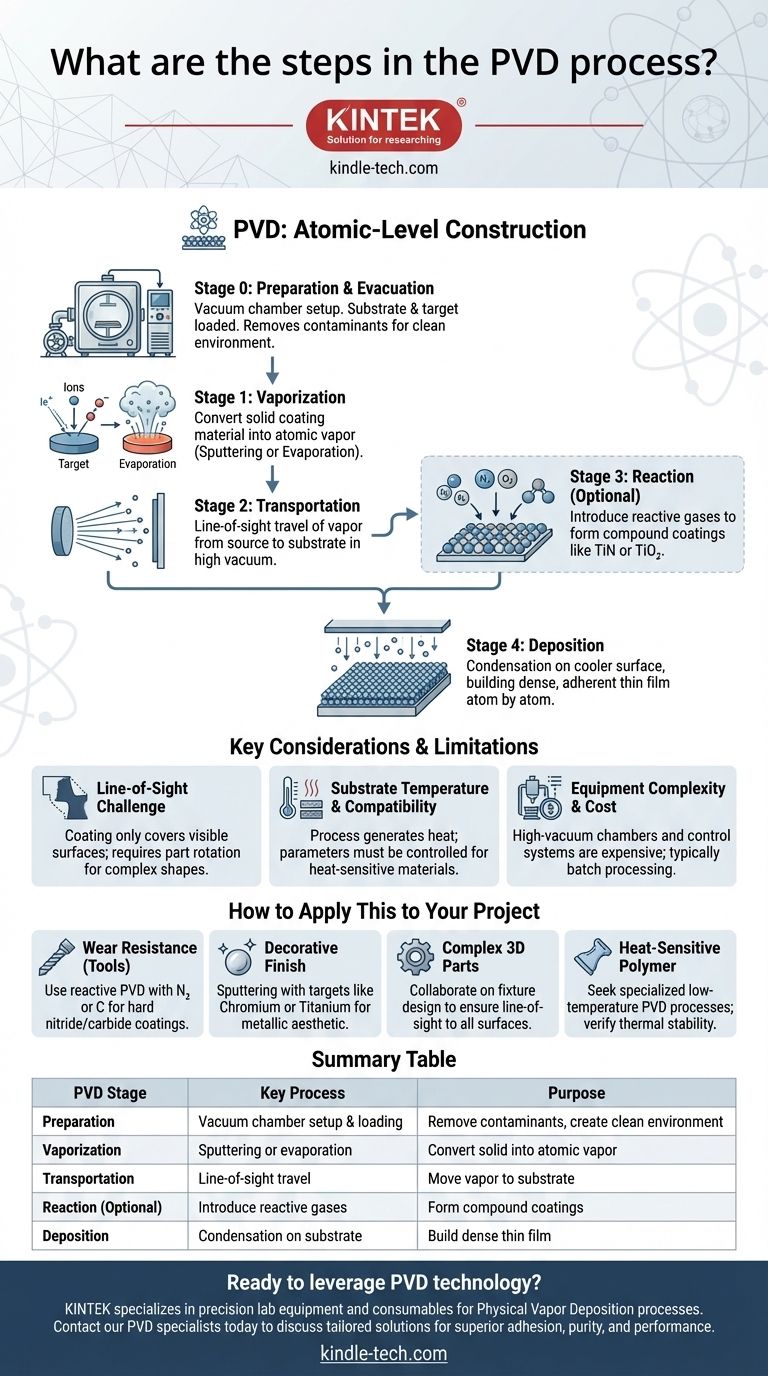

A Detailed Breakdown of the PVD Process

To truly grasp PVD, it is essential to look beyond a simple list and understand the purpose and mechanics of each stage. The process begins before any material is vaporized and requires a highly controlled environment.

Stage 0: Preparation and Evacuation

Before the coating process begins, the parts to be coated (the substrate) and the solid source material to be deposited (the target) are placed inside a sealed chamber.

The chamber is then pumped down to create a high-vacuum environment. This step is critical because it removes air and other gas molecules that could otherwise contaminate the coating or impede the vapor's path to the substrate.

Stage 1: Vaporization – Creating the Coating Material Vapor

This is the "Physical" step in PVD, where a solid material is converted into a gaseous vapor phase using pure physical means.

The most common methods are sputtering, where the target is bombarded with high-energy ions (often from a gas like Argon), knocking atoms loose, or evaporation, where the target is heated until it vaporizes. The choice of method depends on the material being deposited and the desired film properties.

Stage 2: Transportation – Moving from Source to Substrate

Once vaporized, the atoms or molecules of the coating material travel from the target source to the substrate.

In the high-vacuum environment, these particles travel in a straight line, a principle known as line-of-sight deposition. This is why part rotation and fixture design are critical for achieving uniform coverage on complex shapes.

Stage 3: Reaction (Optional) – Forming Compound Materials

For many advanced applications, a simple metallic film is not enough. In these cases, a controlled amount of a reactive gas, such as nitrogen, oxygen, or methane, is introduced into the chamber.

The vaporized metal atoms react with this gas during transport or on the substrate surface. This allows for the formation of highly desirable ceramic compound coatings like Titanium Nitride (TiN) for wear resistance or Titanium Oxide (TiO₂) for optical properties.

Stage 4: Deposition – Building the Thin Film

When the vaporized material reaches the cooler surface of the substrate, it condenses back into a solid state.

This condensation builds up atom by atom, forming a thin, dense, and highly adherent film. The energy of the arriving particles helps ensure a strong physical bond is formed between the coating and the substrate surface, resulting in exceptional durability.

Understanding the Key Considerations and Limitations

While powerful, the PVD process is not without its inherent constraints. Understanding these is crucial for successful application.

The Challenge of Line-of-Sight Deposition

Because the coating material travels in a straight line, any surface not directly "visible" to the vaporization source will not be coated.

This makes coating complex internal geometries or heavily shadowed areas difficult. It often requires sophisticated part-rotation systems or multiple coating cycles from different angles to achieve full coverage.

Substrate Temperature and Material Compatibility

The PVD process generates heat, and the substrate temperature can rise significantly. Although PVD is considered a "low-temperature" process compared to Chemical Vapor Deposition (CVD), it can still be too hot for certain plastics or other heat-sensitive materials.

Process parameters must be carefully controlled to prevent damage or deformation of the substrate.

Equipment Complexity and Cost

PVD requires high-vacuum chambers, sophisticated power supplies, and process-control systems. This equipment is expensive to acquire and maintain.

The process is also typically performed in batches, which can lead to lower throughput compared to continuous processes like electroplating or painting, making it less suitable for very high-volume, low-cost applications.

How to Apply This to Your Project

Understanding these steps allows you to select the right PVD approach for your specific outcome.

- If your primary focus is wear resistance on a tool: You will need a reactive PVD process using nitrogen or carbon to form a hard nitride or carbide coating.

- If your primary focus is a decorative metallic finish: A simpler, non-reactive sputtering process using a target like chromium or titanium may be sufficient.

- If your primary focus is coating a complex 3D part: You must collaborate with the coating provider to design fixtures that ensure all critical surfaces have a line of sight to the source.

- If your primary focus is coating a heat-sensitive polymer: You need to seek out specialized low-temperature PVD processes and verify your material's thermal stability.

By understanding this atomic-level construction process, you can make more informed decisions about its powerful applications.

Summary Table:

| PVD Stage | Key Process | Purpose |

|---|---|---|

| Preparation | Vacuum chamber setup & substrate loading | Remove contaminants, create clean deposition environment |

| Vaporization | Sputtering or evaporation of target material | Convert solid coating material into atomic vapor |

| Transportation | Line-of-sight travel in vacuum | Move vaporized atoms from source to substrate |

| Reaction (Optional) | Introduction of reactive gases (N₂, O₂) | Form compound coatings like TiN or TiO₂ |

| Deposition | Condensation on substrate surface | Build dense, adherent thin film layer by layer |

Ready to leverage PVD technology for your lab's coating needs? KINTEK specializes in precision lab equipment and consumables for Physical Vapor Deposition processes. Whether you require wear-resistant tool coatings, decorative finishes, or specialized thin films for research, our expertise ensures optimal results.

Contact our PVD specialists today to discuss how we can enhance your laboratory's capabilities with tailored solutions that deliver superior adhesion, purity, and performance.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells