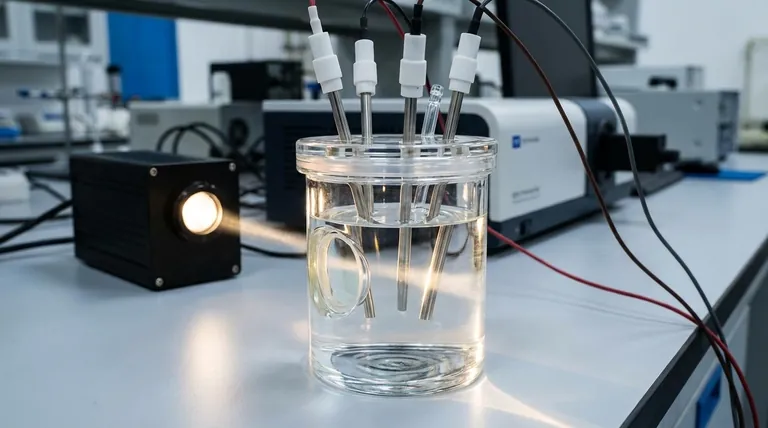

For a side-window optical electrolytic cell, typical specifications include a volume ranging from 10ml to 500ml and a standard aperture configuration designed for a three-electrode system. This usually consists of three 6.2mm diameter ports for the working, counter, and reference electrodes, and two 3.2mm ports for gas inlet and outlet.

The key takeaway is that while standard cell dimensions provide a reliable starting point for common spectroelectrochemical experiments, these specifications are not arbitrary. They are designed to support a specific function—the three-electrode system—and understanding this purpose is crucial for selecting the right cell or customizing one for your specific research needs.

Deconstructing the Cell's Design

An optical electrolytic cell is more than just a container; it's a precision instrument. Each specification serves a distinct purpose in ensuring the integrity of your electrochemical and spectroscopic measurements.

The Role of Volume

Cell volume, typically between 10ml and 500ml, is a critical parameter that impacts your experiment's scale and sensitivity.

Smaller volumes (10ml - 100ml) are often preferred for analytical chemistry. They require less electrolyte and analyte, which is crucial when working with expensive or rare materials.

Larger volumes (100ml - 500ml) are better suited for bulk electrolysis experiments, where the goal is to synthesize a product, or for studies where maintaining a stable bulk concentration over a long period is essential.

Understanding the Aperture Configuration

The arrangement of ports, or apertures, is directly tied to the requirements of a modern electrochemical setup.

The most common configuration includes three larger ports (typically Φ6.2mm). These are sized to accommodate the standard diameters of a working electrode, a counter electrode, and a reference electrode.

Additionally, two smaller ports (typically Φ3.2mm) serve as gas inlets and outlets. These allow you to purge the electrolyte with an inert gas (like nitrogen or argon) to remove dissolved oxygen or to blanket the solution during the experiment.

The Purpose of the Side Window

The defining feature—the "side window"—is a flat, polished surface, usually made of quartz or optical glass. Its sole purpose is to provide a clear, unobstructed path for a light beam to pass through the electrolyte, enabling simultaneous spectroscopic analysis (e.g., UV-Vis or fluorescence) of the species being generated at the electrode surface.

Practical Considerations for Experimental Success

A cell's specifications are only as good as the procedure used to operate it. Rigorous handling and setup are non-negotiable for acquiring reliable data.

Pre-Use Inspection and Cleaning

Before every experiment, perform a thorough inspection. Check the cell body for any cracks or chips and ensure the optical window is clean, transparent, and free of scratches.

Proper cleaning is essential to avoid contamination. A typical procedure involves rinsing with distilled water, followed by soaking in an appropriate organic solvent (like ethanol), and finally drying completely with a stream of clean nitrogen gas.

Correct Electrode Installation

The three electrodes must be installed correctly into their respective ports. Ensure a snug fit and proper sealing to prevent electrolyte leakage, which can compromise your results, damage equipment, and pose a safety hazard.

A poor seal or improper electrode placement can also lead to unstable signals or increased electrical resistance, skewing your electrochemical data.

Controlling the Experimental Environment

The cell's design facilitates environmental control. Use the gas ports to deoxygenate your solution as needed.

Furthermore, you must strictly control parameters like electrolyte concentration and temperature. Fluctuations in these conditions can significantly alter the electrochemical reaction rates and the optical properties of the species you are measuring.

Understanding the Trade-offs

Choosing a cell involves balancing standardized convenience with specific experimental demands.

Standard vs. Custom Design

A standard configuration is efficient and cost-effective for a wide range of common experiments. It is designed to work "out of the box" with most commercially available electrodes.

However, if your experiment involves non-standard equipment—such as a larger custom electrode, a thermocouple, or a pH probe—you will need to request customized apertures with specific diameters or locations.

Material vs. Durability

The use of glass or quartz for the cell body and window is a trade-off. These materials offer excellent optical transparency and general chemical inertness, which are essential for spectroelectrochemistry.

The downside is fragility. These cells must be handled with care to prevent breakage, which can lead to a total loss of the experiment and potential chemical spills. Always ensure the cell is stored in a cool, dry, and secure location away from other chemicals.

Selecting the Right Cell for Your Experiment

Your choice of cell should be driven by your ultimate experimental goal.

- If your primary focus is routine analysis with standard electrodes: A standard cell with a 50-100ml volume and the classic three-electrode (6.2mm) plus two-gas (3.2mm) port configuration is your most reliable and efficient choice.

- If your primary focus is working with precious samples or achieving rapid response times: Opt for a smaller, often custom, volume (10-25ml) to conserve materials and minimize solution resistance (iR drop).

- If your primary focus is integrating specialized sensors or oversized electrodes: You must plan for a custom cell and provide the manufacturer with exact specifications for the required aperture diameters and placements.

Understanding these foundational specifications empowers you to select the precise tool needed to generate clean, reliable, and reproducible spectroelectrochemical data.

Summary Table:

| Specification | Typical Range / Size | Purpose |

|---|---|---|

| Volume | 10ml - 500ml | Balances material usage and experimental scale (analytical vs. bulk electrolysis). |

| Large Apertures | 6.2mm diameter (x3) | Accommodates working, counter, and reference electrodes for a standard three-electrode setup. |

| Small Apertures | 3.2mm diameter (x2) | Used for gas inlet/outlet to purge electrolyte or maintain an inert atmosphere. |

| Side Window Material | Quartz or Optical Glass | Provides a clear optical path for simultaneous spectroscopic analysis (e.g., UV-Vis). |

Ready to achieve precise, reliable spectroelectrochemical results?

KINTEK specializes in high-quality lab equipment and consumables, including optical electrolytic cells designed for accuracy and durability. Whether you need a standard configuration or a custom solution tailored to your unique research requirements, our expertise ensures you get the right tool for your laboratory.

Let's discuss your application needs. Contact our experts today to find the perfect electrolytic cell for your experiments and enhance your research capabilities.

Visual Guide

Related Products

- Electrolytic Electrochemical Cell with Five-Port

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Thin-Layer Spectral Electrolysis Electrochemical Cell

- H Type Electrolytic Cell Triple Electrochemical Cell

- Electrolytic Electrochemical Cell for Coating Evaluation

People Also Ask

- What is the proper way to handle a five-port water bath electrolytic cell? Ensure Accurate and Safe Electrochemical Experiments

- How should the body of an electrolytic cell be maintained for longevity? Extend Your Equipment's Lifespan

- How should the five-port water bath electrolytic cell be cleaned for maintenance? A Step-by-Step Guide to Reliable Results

- How can contamination be avoided during experiments with the five-port water bath electrolytic cell? Master the 3-Pillar Protocol

- What are the proper storage procedures for the multifunctional electrolytic cell? Protect Your Investment and Ensure Data Accuracy