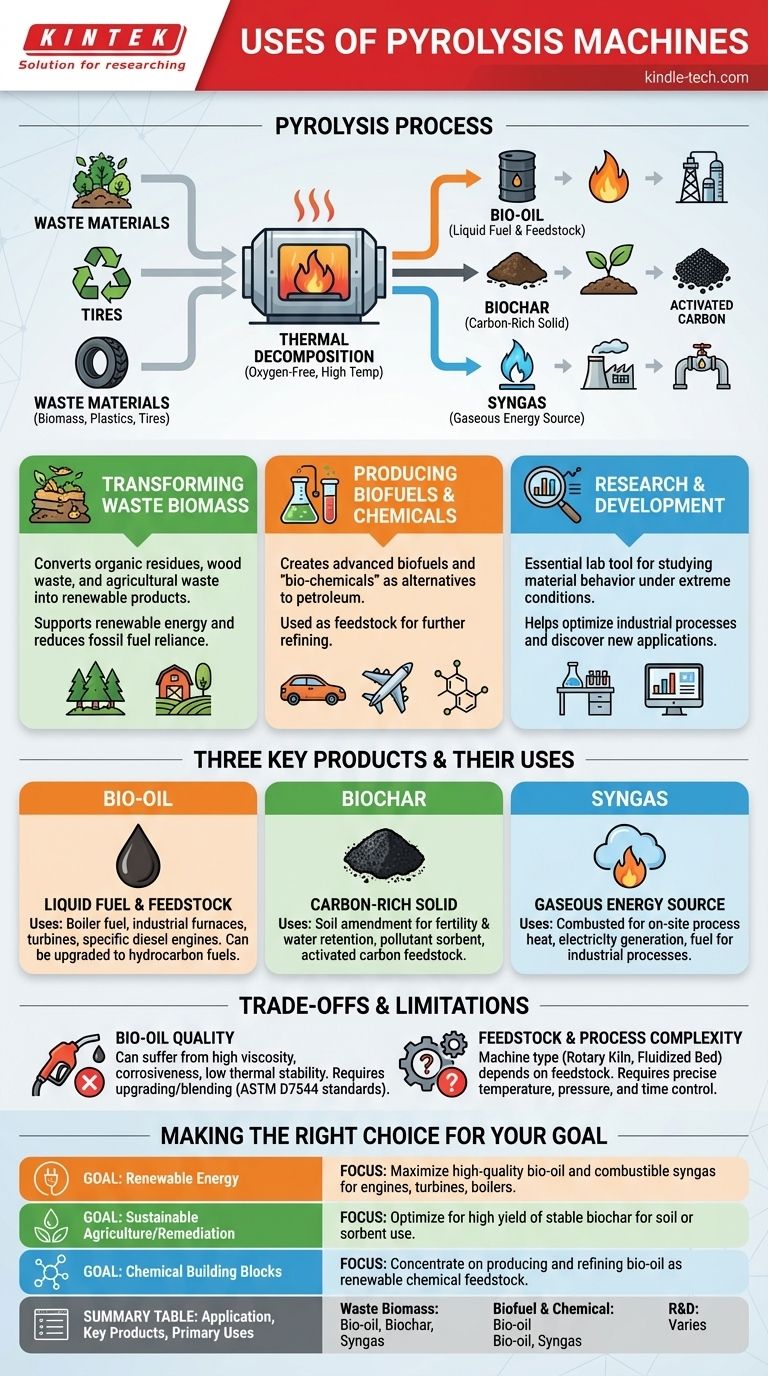

A pyrolysis machine is primarily used to thermally decompose materials like biomass, plastics, or tires at high temperatures in an oxygen-free environment. This process breaks down complex materials into simpler, more valuable products. Its main applications fall into three categories: waste material processing, biofuel production, and chemical manufacturing.

The core function of a pyrolysis machine is not simply waste disposal, but resource transformation. It unlocks the stored energy and chemical components within low-value materials, converting them into marketable products like liquid fuel (bio-oil), a solid carbon amendment (biochar), and a combustible gas (syngas).

The Core Applications: From Waste to Value

A pyrolysis machine, often a rotary kiln or fluidized bed reactor, serves as a bridge between waste streams and new product cycles. It uses intense heat to initiate chemical decomposition without combustion, fundamentally altering the material's structure.

Transforming Waste Biomass

The most common application is converting organic waste into useful products. This includes agricultural residues, wood waste, and other plant-based materials.

This process directly supports the production of renewable energy and reduces reliance on traditional fossil fuels.

Producing Biofuels and Chemicals

Pyrolysis is a key technology in creating advanced biofuels. The resulting products can either be used directly or serve as an intermediate feedstock for further refining.

It also allows for the creation of "bio-chemicals," which can replace petroleum-based products in various manufacturing processes.

Research and Development

In laboratory settings, pyrolysis reactors are essential tools. They allow scientists to study how different materials behave under extreme thermal conditions.

This research helps optimize industrial processes and discover new properties and potential applications for various materials.

The Three Key Products and Their Uses

The value of a pyrolysis machine is best understood through the applications of its three primary outputs: bio-oil, biochar, and syngas.

Bio-oil: The Liquid Fuel and Feedstock

Bio-oil, also known as pyrolysis oil, is a dense, dark liquid. It can be used as a substitute for conventional fuel oil in stationary applications.

Its primary uses include fuel for boilers, industrial furnaces, power generation turbines, and some specially adapted diesel engines. It can also be upgraded in refinery infrastructure to produce hydrocarbon fuels or used as a source for chemical commodities.

Biochar: The Carbon-Rich Solid

Biochar is the stable, charcoal-like solid residue left after the process. Its highly porous structure makes it exceptionally versatile.

It is most commonly used as a soil amendment to improve fertility and water retention in agriculture. It also serves as an effective sorbent for capturing pollutants and as a feedstock for producing high-grade activated carbon.

Syngas: The Gaseous Energy Source

Syngas, or synthesis gas, is a mixture of combustible gases produced during pyrolysis.

This gas can be captured and combusted on-site to provide the heat needed to power the pyrolysis reactor itself, making the process more energy-efficient. It can also be used to generate electricity or as a fuel source for other industrial processes.

Understanding the Trade-offs and Limitations

While powerful, pyrolysis technology is not without its challenges. Understanding its limitations is critical for successful implementation.

The Challenge of Bio-oil Quality

The direct industrial use of raw bio-oil can be limited. The oil often suffers from issues like high viscosity, corrosiveness, and low thermal stability.

These properties mean it often requires upgrading or blending before it can be used as a direct replacement for conventional fuels, and its use is regulated by standards such as ASTM D7544 for stationary applications.

Feedstock and Process Complexity

Pyrolysis is not a one-size-fits-all solution. The type of machine used—such as a rotary kiln versus a fluidized bed reactor—depends heavily on the type and consistency of the feedstock.

Achieving the desired product yields requires precise control over temperature, pressure, and processing time, adding a layer of operational complexity.

Making the Right Choice for Your Goal

The optimal use of a pyrolysis machine depends entirely on your end objective, as the process can be tuned to favor one type of output over another.

- If your primary focus is renewable energy generation: Your goal is to maximize the yield of high-quality bio-oil and combustible syngas for use in engines, turbines, or boilers.

- If your primary focus is sustainable agriculture or remediation: You will optimize the process for a high yield of stable biochar to be used as a soil amendment or pollution sorbent.

- If your primary focus is creating chemical building blocks: Your efforts will concentrate on producing and refining bio-oil as a renewable feedstock for the broader chemical industry.

Ultimately, a pyrolysis machine is a versatile tool for circular economy principles, enabling the conversion of waste liabilities into valuable, sustainable assets.

Summary Table:

| Application | Key Products | Primary Uses |

|---|---|---|

| Waste Biomass Processing | Bio-oil, Biochar, Syngas | Renewable fuel, soil amendment, power generation |

| Biofuel & Chemical Production | Bio-oil, Syngas | Industrial fuel, chemical feedstock |

| Research & Development | Varies | Process optimization, material science studies |

Ready to transform your waste streams into valuable assets? KINTEK specializes in advanced pyrolysis equipment and consumables for laboratories and industrial applications. Whether your goal is renewable energy production, sustainable agriculture, or chemical manufacturing, our solutions are designed to maximize your yield and efficiency. Contact our experts today to discuss how our pyrolysis technology can meet your specific needs and drive your circular economy initiatives forward.

Visual Guide

Related Products

- Customizable Laboratory High Temperature High Pressure Reactors for Diverse Scientific Applications

- Double Plate Heating Press Mold for Lab

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Small Lab Rubber Calendering Machine

People Also Ask

- Why use high-pressure reactors for food waste pretreatment? Boost Hydrogen Production Efficiency Today!

- Why is a high-pressure hydrothermal synthesis autoclave necessary for MnO2 nanowires? Precision Catalyst Growth

- Why are high-strength alloy tube reactors critical for HHIP? Ensuring Safety and Purity in High-Pressure Environments

- Why are high-precision pressure sensors and temperature control systems critical for hydrothermal reaction equilibrium?

- What role does a high-pressure reactor play in the hydrodeoxygenation (HDO) of bio-oil? Drive Deep Fuel Upgrading