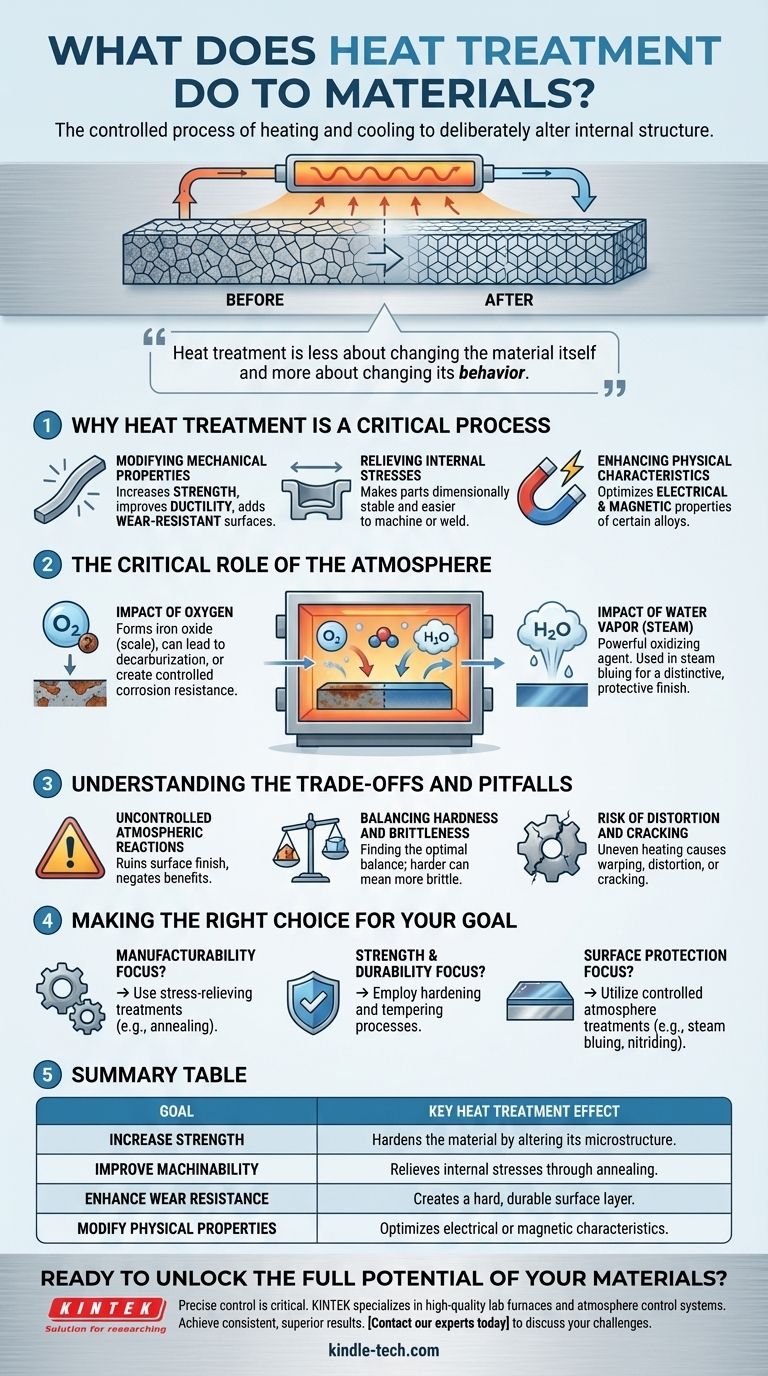

At its core, heat treatment is the controlled process of heating and cooling a material to deliberately alter its internal structure. This manipulation is not superficial; it fundamentally changes a material's physical and mechanical properties. By precisely managing temperature and atmosphere, we can make a metal stronger, more ductile, easier to machine, or more resistant to wear.

Heat treatment is less about changing the material itself and more about changing its behavior. It's a foundational manufacturing process used to unlock a material's hidden potential, tailoring its atomic arrangement to meet specific, demanding performance requirements.

Why Heat Treatment is a Critical Process

The properties of a metal are dictated by its microstructure—the size, shape, and arrangement of its crystalline grains. Heat treatment works by changing this microstructure in predictable ways.

Modifying Mechanical Properties

The primary goal of most heat treatments is to enhance mechanical characteristics. By controlling the heating and cooling cycles, we can significantly increase a material's strength, making it capable of withstanding greater loads.

Simultaneously, we can improve properties like ductility (the ability to deform without fracturing) and introduce exceptional wear-resistant characteristics on a component's surface.

Relieving Internal Stresses

Manufacturing processes like hot forming, casting, or welding introduce significant internal stresses into a material. These stresses can lead to warping, cracking, or premature failure.

Heat treatment allows the material's internal structure to relax and realign. This stress relief makes parts more dimensionally stable and significantly easier to machine or weld accurately.

Enhancing Physical Characteristics

Beyond mechanical strength, heat treatment can also be used to refine a material's physical properties.

This includes optimizing the electrical and magnetic properties of certain alloys, which is critical for components like motor laminations or electrical connectors.

The Critical Role of the Atmosphere

Heat treatment doesn't happen in a vacuum—the gasses surrounding the material play an active and crucial role. What's in the furnace atmosphere can either enhance or ruin the final product.

The Impact of Oxygen

Oxygen readily reacts with hot metals, especially the iron in steel. This reaction forms iron oxide, commonly known as scale, on the surface.

In some cases, this can lead to surface decarburization, where carbon is stripped from the steel's surface, making it softer and weaker. However, some processes intentionally use oxygen to create a controlled oxide layer that provides corrosion resistance.

The Impact of Water Vapor (Steam)

Water vapor is another powerful oxidizing agent at high temperatures. It reacts with iron and can also combine with carbon in steel to form carbon monoxide and hydrogen.

This effect is harnessed in processes like steam bluing. By exposing steel parts to steam at around 700°F (370°C), a uniform, blue-black iron oxide layer is formed, providing both a distinctive finish and a degree of corrosion protection.

Understanding the Trade-offs and Pitfalls

Heat treatment is a science of precision. Failing to control the variables can lead to undesirable outcomes that compromise the integrity of the part.

Uncontrolled Atmospheric Reactions

If the furnace atmosphere isn't carefully managed, the reactions described above can become destructive. Unwanted scale formation can ruin a part's surface finish and dimensional accuracy, while unintended decarburization can negate the benefits of hardening.

Balancing Hardness and Brittleness

A fundamental trade-off in metallurgy is between hardness and brittleness. As you make a material harder, it often becomes more prone to shattering under impact. The goal of many heat treatments is to find the optimal balance, increasing strength without creating a fragile component.

The Risk of Distortion and Cracking

Rapid or uneven heating and cooling create immense thermal stress within a material. If not managed properly, this stress can cause a part to warp, distort, or even crack during the treatment process, rendering it useless.

Making the Right Choice for Your Goal

Selecting the correct heat treatment process depends entirely on the desired outcome for the final component.

- If your primary focus is manufacturability: Use stress-relieving treatments like annealing to make materials more stable and easier to machine or weld.

- If your primary focus is strength and durability: Employ hardening and tempering processes to achieve the ideal balance of strength, toughness, and wear resistance for high-performance parts.

- If your primary focus is surface protection: Utilize controlled atmospheric treatments like steam bluing or nitriding to create a functional and resilient surface layer.

Ultimately, mastering heat treatment is understanding that a material's final performance is determined by its carefully managed thermal history.

Summary Table:

| Goal | Key Heat Treatment Effect |

|---|---|

| Increase Strength | Hardens the material by altering its microstructure. |

| Improve Machinability | Relieves internal stresses through annealing. |

| Enhance Wear Resistance | Creates a hard, durable surface layer. |

| Modify Physical Properties | Optimizes electrical or magnetic characteristics. |

Ready to unlock the full potential of your materials?

The precise control of temperature and atmosphere is critical to successful heat treatment. KINTEK specializes in high-quality lab furnaces and atmosphere control systems, providing the reliable equipment you need to achieve consistent, superior results.

Whether you are developing new alloys or optimizing production processes, our expertise in lab equipment can help you enhance strength, improve durability, and meet your most demanding performance requirements.

Contact our experts today to discuss your specific heat treatment challenges and discover the right solution for your laboratory.

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- What is the ashing method? A Guide to Analyzing Sample Composition with Precision

- Why is a Muffle furnace required for the preparation of titanium components? Optimize Passivation and Resistance

- Why is a benchtop constant temperature drying oven used in TiO2 reactor fabrication? Ensure Superior Catalyst Adhesion

- Why is an oxygen-containing medium required during muffle furnace annealing of cerium dioxide? - Preserve Material Integrity

- What is the role of a high-temperature box furnace in Si-doped TiO2 preparation? Precision for Photocatalysis

- What are the conditions for sintering? Achieve Optimal Material Density and Strength

- What is the high temperature of a muffle furnace? From 1100°C to 1700°C+ for Your Lab Needs

- Why is a high-temperature muffle furnace required for the preparation of calcium oxide nanoparticles? Expert Guide