At its core, heat treatment fundamentally alters a material's microstructure to achieve specific, desirable mechanical properties. By precisely controlling temperature and cooling rates, you can manipulate the arrangement of atoms within the material, changing everything from its hardness and strength to its ductility and toughness. This is not just a surface change; it is a complete restructuring of the material from the inside out.

Heat treatment is the deliberate use of thermal energy to give atoms the mobility to rearrange themselves. This allows an engineer to eliminate internal defects, control the size and shape of crystal grains, and even create entirely new crystal phases to tailor a material's final performance.

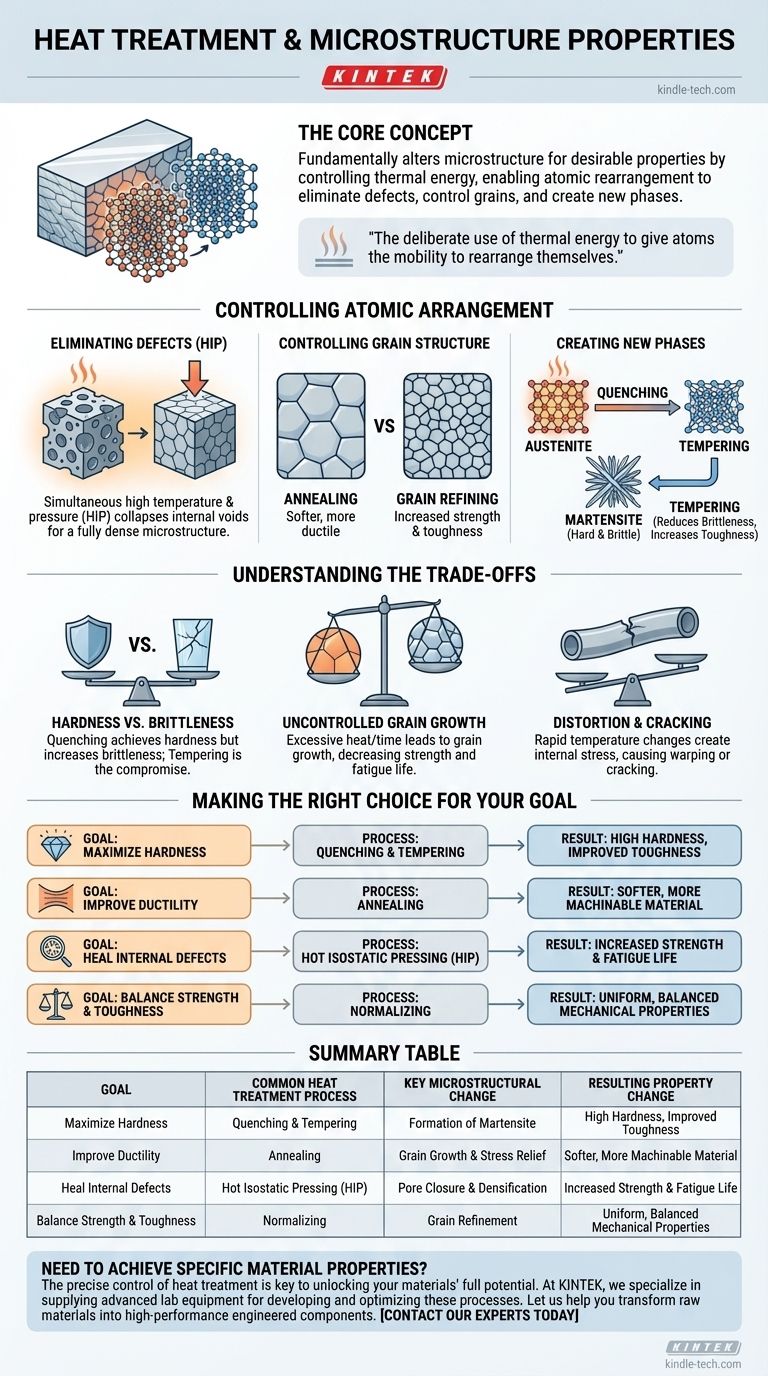

The Fundamental Goal: Controlling Atomic Arrangement

The properties of a metallic component are dictated by its internal microstructure—the specific arrangement of its atoms into crystals, or "grains." Heat treatment provides the energy needed to modify this arrangement in a controlled way.

Eliminating Internal Defects

Many manufacturing processes, like casting or 3D printing, can leave behind microscopic internal voids or pores. These defects act as stress concentrators and are weak points where cracks can initiate.

Specialized heat treatments, such as Hot Isostatic Pressing (HIP), apply both high temperature and immense pressure simultaneously. This forces the material to deform on a microscopic level, causing internal voids to collapse and diffusion bond shut, resulting in a fully dense and uniform microstructure.

Controlling Grain Structure

The size and orientation of the crystal grains have a massive impact on mechanical properties.

Annealing is a process where a material is heated and then slowly cooled. This gives atoms time to form new, strain-free grains and allows existing grains to grow. The result is typically a softer, more ductile, and more easily machined material.

Conversely, other thermal cycles can be used to refine the grain size (make the grains smaller), which generally increases a material's strength and toughness.

Creating New Crystalline Phases

Perhaps the most powerful use of heat treatment is inducing phase transformations. Think of it like changing water (a liquid phase) to ice (a solid phase); metals can be changed from one solid crystal structure to another.

In steel, heating it to a high temperature transforms it into a phase called austenite. If you then cool it extremely rapidly (quenching), the atoms are trapped in a new, highly strained, and very hard structure called martensite.

This newfound hardness often comes with brittleness, so a subsequent lower-temperature treatment called tempering is used. Tempering allows a slight atomic rearrangement to relieve some strain, which reduces brittleness and increases overall toughness.

Understanding the Trade-offs

Heat treatment is a balancing act. Improving one property often comes at the expense of another. Understanding these compromises is critical for success.

Hardness vs. Brittleness

This is the classic trade-off. A process like quenching creates extreme hardness but makes the material brittle and susceptible to fracture. Tempering is the compromise, sacrificing some peak hardness to regain essential toughness.

Uncontrolled Grain Growth

While annealing can be beneficial, holding a material at a high temperature for too long can cause excessive grain growth. Overly large grains can decrease strength, toughness, and fatigue life. The key is precise control over both temperature and time.

Distortion and Cracking

Rapid changes in temperature, especially during quenching, create immense internal stresses as the material expands and contracts unevenly. Without proper technique, this can cause the component to warp out of shape or, in extreme cases, crack.

Making the Right Choice for Your Goal

The correct heat treatment process is entirely dependent on your end goal.

- If your primary focus is maximizing hardness and wear resistance: A rapid quench to form a hard phase like martensite, followed by a low-temperature temper, is the most effective path.

- If your primary focus is improving ductility for forming or machining: A full anneal with a slow cool-down cycle will soften the material and relieve internal stresses.

- If your primary focus is healing internal defects from manufacturing: A process like Hot Isostatic Pressing (HIP) is required to apply both heat and pressure to achieve full densification.

- If your primary focus is a balanced combination of strength and toughness: A normalizing or a quench-and-temper process provides the most flexibility to achieve a robust set of properties.

Ultimately, heat treatment is the essential tool that transforms a raw material into a high-performance engineered component.

Summary Table:

| Goal | Common Heat Treatment Process | Key Microstructural Change | Resulting Property Change |

|---|---|---|---|

| Maximize Hardness | Quenching & Tempering | Formation of Martensite | High Hardness, Improved Toughness |

| Improve Ductility | Annealing | Grain Growth & Stress Relief | Softer, More Machinable Material |

| Heal Internal Defects | Hot Isostatic Pressing (HIP) | Pore Closure & Densification | Increased Strength & Fatigue Life |

| Balance Strength & Toughness | Normalizing | Grain Refinement | Uniform, Balanced Mechanical Properties |

Need to achieve specific material properties for your components?

The precise control of heat treatment is key to unlocking the full potential of your materials, whether you require maximum hardness, improved ductility, or a balanced set of mechanical properties. At KINTEK, we specialize in supplying the advanced lab equipment necessary for developing and optimizing these critical thermal processes.

Let us help you transform your raw materials into high-performance engineered components. Contact our experts today to discuss how our solutions can meet your specific laboratory and production needs.

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- What is a furnace used for sintering? Creating High-Performance Solid Components from Powder

- How do you lower sintering temperature? Achieve Dense Materials at Lower Costs

- How do precision-controlled high-temperature furnaces assist e-waste recycling? Localized Material Recovery Solutions

- What is the purpose of a vacuum furnace? Achieve Unmatched Material Purity and Performance

- Why do you heat treat in a vacuum? Achieve Perfect Surface Finish and Material Integrity

- How does a sealed quench furnace work? A Complete Guide to Controlled Heat Treatment

- What is the function of a high-precision industrial furnace for Alloy 718? Master Strengthening & Microstructure Control

- What is vacuum furnace brazing? Achieve Superior Metal Joining with Unmatched Purity