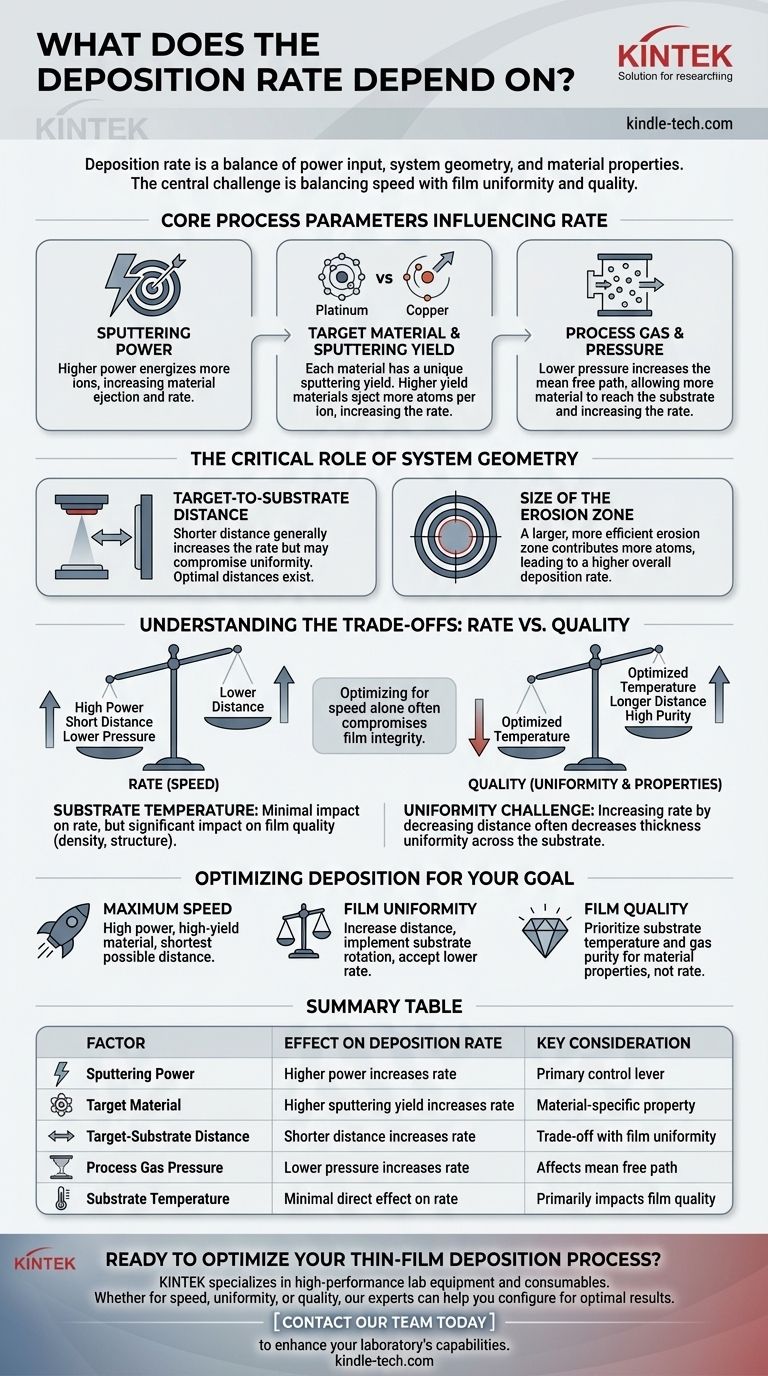

Fundamentally, the deposition rate in a thin-film process is determined by a combination of your power input, your system's physical geometry, and the specific material you are depositing. While increasing power or decreasing the distance between the source and the substrate are the most direct ways to increase the rate, these actions have direct consequences on the uniformity and quality of the final film.

The central challenge is not simply maximizing the deposition rate, but balancing it against the equally important goals of film uniformity and quality. Optimizing for speed alone often compromises the integrity of the material you are creating.

Core Process Parameters Influencing Rate

The speed at which your film grows is a direct result of the energy you put into the system and the material's response to that energy.

Sputtering Power

The amount of power applied to the magnetron is a primary lever for controlling the rate. Higher power energizes more ions in the plasma, causing them to strike the target material with greater force and frequency.

This ejects more target atoms, directly increasing the flux of material traveling toward your substrate and thus increasing the deposition rate.

Target Material & Sputtering Yield

The material of the target itself is a critical factor. Each material has a unique property called sputtering yield—the average number of atoms ejected from the target for each ion that strikes it.

For example, a platinum target has a lower sputtering yield than many other common metals. As a result, it will produce a deposition rate roughly half that of other materials under the exact same process conditions.

Process Gas & Pressure

The pressure of the process gas (like Argon) inside the chamber directly impacts the rate. Lower pressure means there are fewer gas atoms for the ejected target material to collide with on its way to the substrate.

This longer "mean free path" results in more material reaching the substrate, increasing the deposition rate. Conversely, higher pressure leads to more collisions and scattering, which slows the rate down.

The Critical Role of System Geometry

How your deposition chamber is physically configured has a profound and often overlooked impact on both the rate and the final film characteristics.

Target-to-Substrate Distance

As a general rule, the deposition rate has an inverse relationship with the distance between the target and the substrate. Bringing the substrate closer to the source increases the rate.

However, in some specific plasma processes, there can be an optimal distance (e.g., a few millimeters from the electrode) where the plasma density is at its peak, momentarily maximizing the rate before it begins to decrease again with more distance.

Size of the Erosion Zone

The deposition rate is strongly influenced by the size of the erosion zone on the target. This is the area of the target that is actively being sputtered.

A larger, more efficiently used erosion zone means a greater surface area is contributing sputtered atoms, leading to a higher overall deposition rate for a given power level.

Understanding the Trade-offs: Rate vs. Quality

Experienced engineers know that chasing the highest possible deposition rate is often a mistake. The most important parameters for film quality do not necessarily increase speed.

The Substrate Temperature Dilemma

Substrate temperature has very little direct impact on the deposition rate itself. However, it has a significant impact on the quality of the film.

Higher substrate temperatures give the arriving atoms more surface energy, allowing them to arrange themselves into a more ordered and dense structure. This reduces defects and improves the film's physical properties, but it does not make the process faster.

The Uniformity Challenge

The trade-off between rate and uniformity is constant. Decreasing the target-to-substrate distance to increase the rate will almost always decrease the thickness uniformity of the film across the substrate.

Material deposits most heavily directly beneath the erosion track, and this effect becomes more pronounced at shorter distances. Achieving a highly uniform film often requires increasing the distance, which in turn lowers the rate.

Optimizing Deposition for Your Goal

To control your process effectively, you must first define your primary objective. The ideal parameters for one goal are often wrong for another.

- If your primary focus is maximum speed: Use high power, a high-yield target material, and the shortest possible target-substrate distance that your system allows.

- If your primary focus is film uniformity: Increase the target-to-substrate distance and consider implementing substrate rotation, accepting the resulting decrease in deposition rate.

- If your primary focus is film quality (e.g., density, low stress): Prioritize optimizing substrate temperature and process gas purity, as these have a greater impact on material properties than on the rate.

Mastering thin-film deposition is about understanding and intentionally manipulating the interplay between these competing variables.

Summary Table:

| Factor | Effect on Deposition Rate | Key Consideration |

|---|---|---|

| Sputtering Power | Higher power increases rate | Primary control lever |

| Target Material | Higher sputtering yield increases rate | Material-specific property |

| Target-Substrate Distance | Shorter distance increases rate | Trade-off with film uniformity |

| Process Gas Pressure | Lower pressure increases rate | Affects mean free path of atoms |

| Substrate Temperature | Minimal direct effect on rate | Primarily impacts film quality |

Ready to Optimize Your Thin-Film Deposition Process?

Understanding the delicate balance between deposition rate, uniformity, and quality is key to successful research and production. KINTEK specializes in providing high-performance lab equipment and consumables tailored to your specific thin-film needs.

Whether you are prioritizing speed, uniformity, or superior film quality, our experts can help you select the right sputtering targets and configure your system for optimal results.

Contact our team today to discuss how KINTEK's solutions can enhance your laboratory's capabilities and achieve your material science goals.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What are the advantages and disadvantages of hot pressing? Choose the Right Powder Metallurgy Process

- What is vacuum lamination? Achieve a Flawless, Durable Finish on Complex Shapes

- What is hot press forging? Creating Complex, High-Strength Metal Components

- What is hot press moulding? Achieve Superior Density and Complex Shapes with Heat and Pressure

- Why is a vacuum hot-pressing furnace preferred for C_fiber/Si3N4 composites? Achieve High Density & Fiber Protection