Fundamentally, pressure acts as an accelerator and a densifier in the sintering process. By physically forcing material particles together, external pressure dramatically enhances the rate at which voids and pores are eliminated. This allows for the creation of a dense, solid part at lower temperatures and in less time than relying on heat alone.

While heat provides the energy for atoms to bond, pressure provides the driving force that ensures particles are in intimate contact. This synergy is the key to achieving high-performance materials with minimal defects.

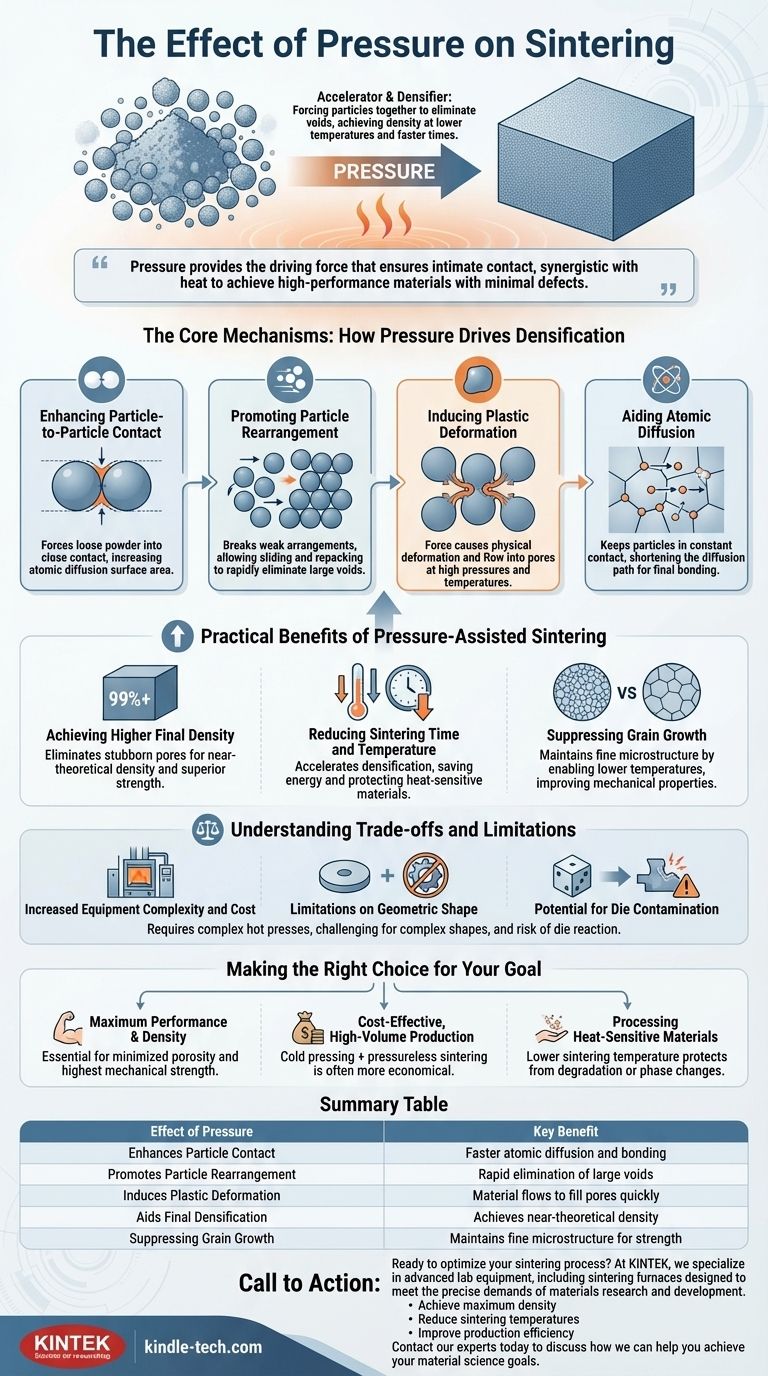

The Core Mechanisms: How Pressure Drives Densification

To understand the effect of pressure, it's useful to see it as a force that actively helps the heat do its job more efficiently. It accomplishes this through several key mechanisms that occur during the process.

Enhancing Particle-to-Particle Contact

The first and most obvious effect of pressure is mechanical. It forces the loose powder particles into close contact, increasing the surface area where the atomic bonding, known as atomic diffusion, can occur.

Without pressure, particles only touch at a few small points, requiring atoms to travel farther to close the gaps.

Promoting Particle Rearrangement

In the initial stages, pressure breaks down weak particle arrangements and bridges. This allows the particles to slide and repack into a much denser configuration before significant bonding even begins, rapidly eliminating large voids.

Inducing Plastic Deformation

At higher pressures and temperatures, the force becomes great enough to physically deform the particles at their contact points. This plastic deformation causes the material to flow into the surrounding pores, a much faster mechanism for densification than relying solely on atomic diffusion.

Aiding Atomic Diffusion

Ultimately, sintering is completed when atoms diffuse across the boundaries of adjacent particles, effectively erasing the boundary and joining them into a single grain. Pressure aids this process by keeping the particles in constant, intimate contact, shortening the diffusion path for atoms to travel.

The Practical Benefits of Pressure-Assisted Sintering

Applying pressure isn't just a theoretical improvement; it yields tangible benefits in the final product and the manufacturing process itself.

Achieving Higher Final Density

Pressure is exceptionally effective at eliminating the last, most stubborn pores that can remain trapped within the material. This allows for the production of parts with a final density that is much closer to the material's theoretical maximum, leading to superior strength.

Reducing Sintering Time and Temperature

Because pressure so effectively accelerates densification, the same target density can be achieved in significantly less time or at a lower temperature. This reduction saves energy, increases throughput, and can be critical for materials that are sensitive to high heat.

Suppressing Grain Growth

A common side effect of high-temperature, long-duration sintering is grain growth, where the material's internal crystals enlarge. This often weakens the final part. By enabling lower temperatures and shorter times, pressure helps maintain a fine-grained microstructure, which is directly linked to improved mechanical properties like hardness and toughness.

Understanding the Trade-offs and Limitations

Despite its significant advantages, incorporating pressure is not a universal solution. It introduces complexities and constraints that must be considered.

Increased Equipment Complexity and Cost

Sintering furnaces that incorporate pressure, such as a hot press, are significantly more complex and expensive than simple atmospheric furnaces. The operational costs are also higher.

Limitations on Geometric Shape

Applying uniform pressure is most effective on parts with simple geometries, like discs or blocks. It is very difficult to ensure even pressure distribution on complex, three-dimensional shapes, which can lead to warping or inconsistent density.

Potential for Die Contamination

The part being sintered is held within a die (typically graphite or ceramic) that applies the pressure. At very high temperatures, there is a risk that the part material may react with or adhere to the die, introducing contamination or causing damage during removal.

Making the Right Choice for Your Goal

The decision to use pressure in sintering depends entirely on the desired outcome for the final component.

- If your primary focus is maximum performance and density: Pressure-assisted sintering is essential to minimize porosity and create parts with the highest possible mechanical strength.

- If your primary focus is cost-effective, high-volume production: A two-stage process of cold pressing a "green part" followed by pressureless sintering is often the most economical approach for less critical applications.

- If your primary focus is processing heat-sensitive materials: Using pressure allows you to significantly lower the sintering temperature, protecting materials that might otherwise degrade or undergo undesirable phase changes.

Ultimately, leveraging pressure transforms sintering from a purely heat-driven process into a highly controlled engineering tool for creating superior materials.

Summary Table:

| Effect of Pressure | Key Benefit |

|---|---|

| Enhances Particle Contact | Faster atomic diffusion and bonding |

| Promotes Particle Rearrangement | Rapid elimination of large voids |

| Induces Plastic Deformation | Material flows to fill pores quickly |

| Aids Final Densification | Achieves near-theoretical density |

| Suppresses Grain Growth | Maintains fine microstructure for strength |

Ready to optimize your sintering process?

Pressure-assisted sintering is key to creating high-performance materials with superior density and strength. At KINTEK, we specialize in advanced lab equipment, including sintering furnaces designed to meet the precise demands of materials research and development.

Our expertise can help you:

- Achieve maximum density and mechanical performance in your samples.

- Reduce sintering temperatures to protect heat-sensitive materials.

- Improve production efficiency with faster cycle times.

Whether you're developing new alloys, ceramics, or advanced composites, KINTEK has the solutions to support your laboratory's sintering needs. Contact our experts today to discuss how we can help you achieve your material science goals.

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

People Also Ask

- What are the applications of cold isostatic pressing? Achieve Uniform Density for Complex Parts

- Why is cold working better than hot working? A Guide to Choosing the Right Metal Forming Process

- How much does an isostatic press cost? A Guide to Lab vs. Industrial Pricing

- What are the disadvantages of powder metallurgy? Key Limitations in Strength and Size

- What is a cold isostatic press? Achieve Uniform Powder Compaction for Complex Parts