In short, compressing hot metal forces it to permanently change shape without breaking, a process known as plastic deformation. The heat is the critical element, making the metal soft and malleable enough to be formed. This action is the foundation of manufacturing processes like forging, rolling, and extrusion.

Compressing hot metal is not merely about reshaping it. The true purpose is to control and refine its internal crystalline structure, a process called recrystallization, which ultimately determines the material's final strength, toughness, and durability.

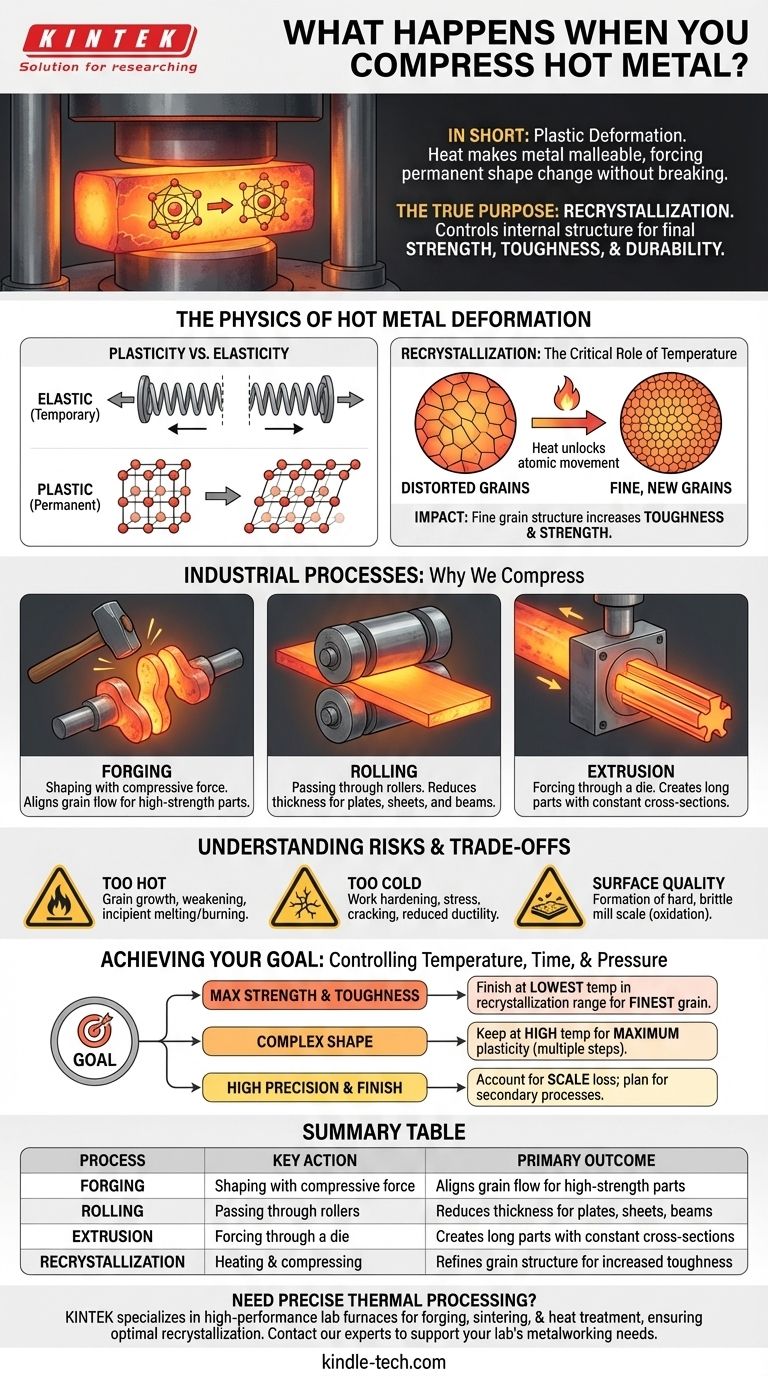

The Physics of Hot Metal Deformation

To understand what happens during compression, we must look at the metal on a microscopic level. The properties we observe are a direct result of the behavior of its internal crystal structure.

Plasticity vs. Elasticity

All solid materials exhibit some degree of elasticity and plasticity. Elastic deformation is temporary; like a rubber band, the material returns to its original shape once the force is removed.

Plastic deformation is permanent. When you compress hot metal, you are applying enough force to exceed its elastic limit. The atoms within its crystal lattice are forced to slip past one another into new, stable positions, permanently altering the object's shape.

The Critical Role of Temperature: Recrystallization

Heat is the key that unlocks plastic deformation. At high temperatures (typically above 40-50% of its melting point), the atoms in the metal have enough energy to move around.

When the metal is compressed, its internal crystals, called grains, become distorted and stressed. The heat immediately allows new, smaller, strain-free grains to form and grow, replacing the old distorted ones. This dynamic process is called recrystallization.

The Impact on Grain Structure

Recrystallization is the goal of hot working. The process breaks down large, coarse grains into a much finer, more uniform grain structure.

A fine grain structure is highly desirable. It increases the metal's toughness (resistance to fracture) and strength. By controlling the temperature and the amount of compression, engineers can precisely tailor these final properties.

Why We Compress Hot Metal: Industrial Processes

This principle of hot deformation is the backbone of heavy industry. It's how we transform raw metal ingots into useful, high-performance components.

Forging

Forging involves shaping metal using localized compressive forces, often with a hammer or a press. This process is used to create critical, high-strength parts like engine crankshafts, turbine blades, and tools.

A key benefit of forging is that it aligns the internal grain flow with the shape of the part, making it exceptionally strong and resistant to fatigue along the lines of stress.

Rolling

Hot rolling is a process where metal is passed through one or more pairs of massive rollers to reduce its thickness and make it uniform. This is how we produce steel plates for ships, I-beams for construction, and sheets for car bodies.

Extrusion

In extrusion, a hot metal billet is forced through a shaped die, emerging as a long part with a constant cross-section. This method is perfect for producing items like aluminum window frames, pipes, and complex structural rails.

Understanding the Trade-offs and Risks

While powerful, working with hot metal requires precise control. Deviating from the optimal process can severely compromise the material's integrity.

The Risk of Working Too Hot

If the metal's temperature is too high, its grains can grow excessively large. This grain growth weakens the material, reducing its toughness and making it brittle. In extreme cases, overheating can lead to incipient melting at the grain boundaries or burning (rapid oxidation), rendering the part useless.

The Danger of Working Too Cold

If the metal cools too much during compression, recrystallization slows down or stops entirely. Instead, the material begins to work harden—the grains become distorted and elongated without being replaced by new ones. This rapidly increases internal stress, reduces ductility, and can lead to surface cracking or catastrophic failure during the process.

Surface Quality and Oxidation

A significant downside of hot working is the formation of a hard, brittle layer of iron oxide, or mill scale, on the surface. This scale must be removed, and it can affect the final dimensions and surface finish of the component, often requiring secondary machining operations.

Making the Right Choice for Your Goal

Controlling the interplay between temperature, time, and pressure is how metallurgists and engineers achieve specific outcomes.

- If your primary focus is maximizing strength and toughness: Your goal is to finish the compression process at the lowest possible temperature within the recrystallization range to achieve the finest possible grain structure.

- If your primary focus is achieving a complex shape: Your goal is to keep the material at a high temperature to ensure maximum plasticity, often using multiple heating and compression steps to prevent it from cooling and work hardening.

- If your primary focus is high precision and surface finish: You must account for material loss from scale and may need to use controlled atmospheres or plan for subsequent cold-working or machining processes.

Ultimately, mastering hot metal compression is about using force not just to change an object's external shape, but to intentionally engineer its internal structure for superior performance.

Summary Table:

| Process | Key Action | Primary Outcome |

|---|---|---|

| Forging | Shaping with compressive force | Aligns grain flow for high-strength parts |

| Rolling | Passing through rollers | Reduces thickness for plates, sheets, and beams |

| Extrusion | Forcing through a die | Creates long parts with constant cross-sections |

| Recrystallization | Heating & compressing | Refines grain structure for increased toughness |

Need precise thermal processing for your materials? KINTEK specializes in high-performance lab furnaces and equipment that deliver the exact temperature control required for successful hot metal compression processes like forging, sintering, and heat treatment. Our solutions help you achieve optimal recrystallization and superior material properties. Contact our experts today to discuss how we can support your laboratory's metalworking and research needs.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Warm Isostatic Press for Solid State Battery Research

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Electric Heated Hydraulic Vacuum Heat Press for Lab

People Also Ask

- What role does a high-temperature hot press play in the sintering of NITE-SiC? Optimize Your Densification Process

- How does the uniaxial pressing function of a vacuum hot press furnace influence the microstructure of ZrC-SiC ceramics?

- What conditions does a Vacuum Hot Pressing Furnace provide for Copper-MoS2-Mo composites? Achieve Peak Densification

- Why is a vacuum essential for sintering metal-ceramic composites? Achieve Pure, High-Density Results

- What are the advantages of using a vacuum hot press sintering furnace? Achieve 99.1% Density in CuW30 Composites