For large castings, the most common and often required heat treatment is a form of annealing, specifically for stress relief. This process is crucial for mitigating the immense internal stresses that develop during the cooling of a large, thick metal part. However, the specific process required depends entirely on the alloy and the final mechanical properties needed for the application.

The central challenge with large castings is not just achieving hardness, but managing the inevitable internal stresses and inconsistent microstructure caused by uneven cooling. Therefore, the primary goal of heat treatment is to restore uniformity and stability, with subsequent treatments used to develop specific performance attributes.

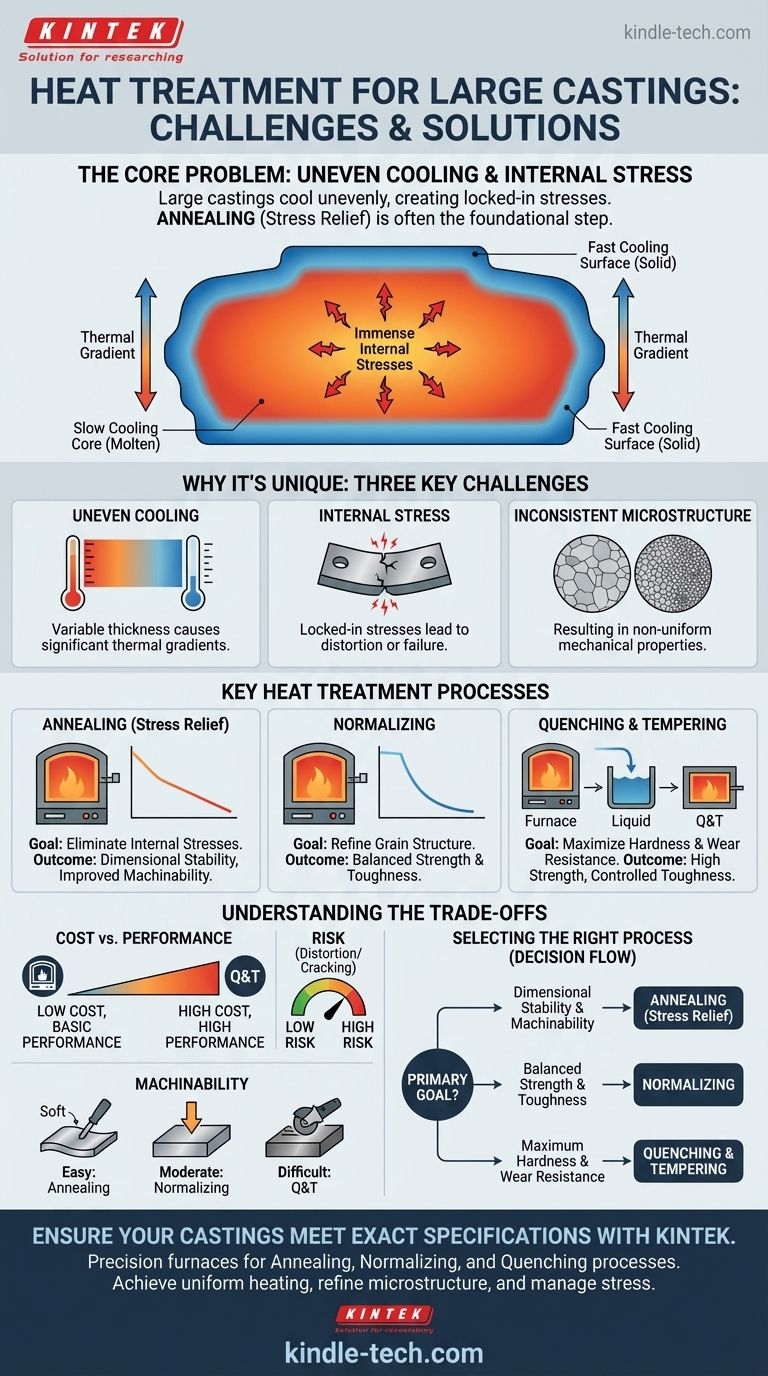

Why Large Castings Present a Unique Challenge

To select the right heat treatment, you must first understand the inherent problems that arise when casting large metal components. The sheer mass and variable thickness are the root cause of these issues.

The Problem of Uneven Cooling

The outer surface of a large casting cools and solidifies much faster than its insulated, molten core.

This temperature difference, or thermal gradient, across the part's cross-section is the source of nearly all subsequent problems.

Internal Stress and Its Consequences

As different sections of the casting cool and shrink at different rates, they pull against each other. This creates immense internal stresses that become locked into the material.

Without treatment, these stresses can lead to distortion over time, during machining, or even cause spontaneous cracking and catastrophic failure.

Inconsistent Microstructure

The rate of cooling dictates the final crystalline structure (microstructure) of the metal.

A fast-cooling surface will have a different, often finer grain structure than the slow-cooling core. This results in a component with inconsistent mechanical properties, such as hardness and strength, from the outside to the inside.

Key Heat Treatment Processes for Large Castings

Heat treatments are controlled heating and cooling cycles designed to manipulate the metal's microstructure and resolve the issues above. They are typically performed in large, precisely controlled furnaces.

Annealing (Stress Relief): The Foundational Step

Annealing is the most fundamental process for large castings. The component is heated to a specific temperature, held at that temperature to allow the entire part to equalize, and then cooled very slowly inside the furnace.

This slow, controlled cycle allows the metal's internal crystal structure to realign, effectively relaxing and eliminating the locked-in internal stresses. It also softens the metal, improves ductility, and creates a uniform microstructure, which significantly aids in subsequent machining.

Normalizing: Refining the Grain Structure

Normalizing is similar to annealing but involves a faster cooling stage, typically by removing the part from the furnace and letting it cool in the open air.

This moderately faster cool produces a more refined and uniform grain structure compared to an annealed state. The result is a casting with higher strength and hardness than one that has been annealed, while still relieving most internal stresses.

Quenching and Tempering: For Maximum Strength and Hardness

This is a two-step process used for high-performance applications. First, the casting is heated and then rapidly cooled, or quenched, in a liquid medium like water, oil, or a polymer solution.

Quenching freezes a very hard and brittle microstructure (like martensite in steel) in place. Because this state is too brittle for most uses, it is immediately followed by tempering—reheating the part to a lower temperature to reduce brittleness and impart a specific level of toughness.

Understanding the Trade-offs

Choosing a heat treatment is an engineering decision with clear trade-offs. No single process is universally "best."

Cost vs. Performance

Complexity and time dictate cost. A simple stress relief anneal is the least expensive. Multi-step processes like quenching and tempering require more furnace time, specialized equipment, and risk, making them significantly more expensive.

The Risk of Distortion and Cracking

Aggressive treatments, especially quenching, introduce a high degree of thermal shock. For large, complex geometries, this can cause the part to warp or even crack during the process. This risk must be carefully managed through process control and is a major reason why annealing or normalizing is often preferred.

Machinability Considerations

Heat treatment directly impacts how easily the material can be cut.

- Annealing creates the softest, most easily machinable state.

- Normalizing results in a slightly harder material that is still readily machinable.

- Quenched and Tempered parts can be extremely hard and difficult or impossible to machine, often requiring specialized grinding operations.

Selecting the Right Process for Your Application

Your choice must be driven by the component's end-use and manufacturing plan.

- If your primary focus is dimensional stability and machinability: Stress Relief Annealing is the essential first step to ensure the part does not warp during machining and is easy to work with.

- If your primary focus is a good balance of strength and toughness: Normalizing provides a significant improvement in mechanical properties over the as-cast state without the high risk and cost of liquid quenching.

- If your primary focus is maximum hardness and wear resistance: Quenching and Tempering is the required path, but it must be carefully planned to account for the high risk of distortion and the difficulty of final machining.

Ultimately, the correct heat treatment transforms a raw casting from an inconsistent and unstable object into a reliable, engineered component.

Summary Table:

| Process | Primary Goal | Key Outcome |

|---|---|---|

| Annealing (Stress Relief) | Eliminate internal stresses | Dimensional stability, improved machinability |

| Normalizing | Refine grain structure | Balanced strength and toughness |

| Quenching & Tempering | Maximize hardness and wear resistance | High strength, controlled toughness |

Ensure your large castings meet exact specifications with KINTEK's precision heat treatment solutions.

We specialize in providing advanced laboratory furnaces and consumables tailored for annealing, normalizing, and quenching processes. Our equipment delivers precise temperature control and uniform heating—critical for managing stress, refining microstructure, and achieving the mechanical properties your application demands.

Whether you're in aerospace, automotive, or heavy machinery, KINTEK helps you transform raw castings into reliable, high-performance components.

Contact our experts today to discuss your project requirements and discover the right heat treatment solution for your needs.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Tube Furnace

People Also Ask

- Why do we use muffle furnace? For Unmatched Purity and Precision in High-Temp Processing

- Why do we need to use properly some of the laboratory apparatus in the laboratory? The Foundation of Safe and Accurate Science

- What temperature does steel liquify? Understanding the Melting Range for Your Applications

- What is the use of muffle furnace in food analysis? Master Ashing for Accurate Mineral Content

- What is the meaning of muffle furnace? The Key to Pure, High-Temperature Processing