The primary heat treatment process used to soften materials, improve ductility, and relieve internal stresses is known as annealing. This controlled process involves heating a metal or alloy to a specific temperature, holding it at that temperature for a sufficient duration, and then allowing it to cool at a very slow, controlled rate. This "resets" the material's internal structure, making it easier to work with.

The core purpose of annealing is not simply to soften a material, but to strategically manipulate its microstructure. It is a foundational process used to reverse the effects of work hardening and prepare the material for subsequent forming, machining, or other manufacturing steps.

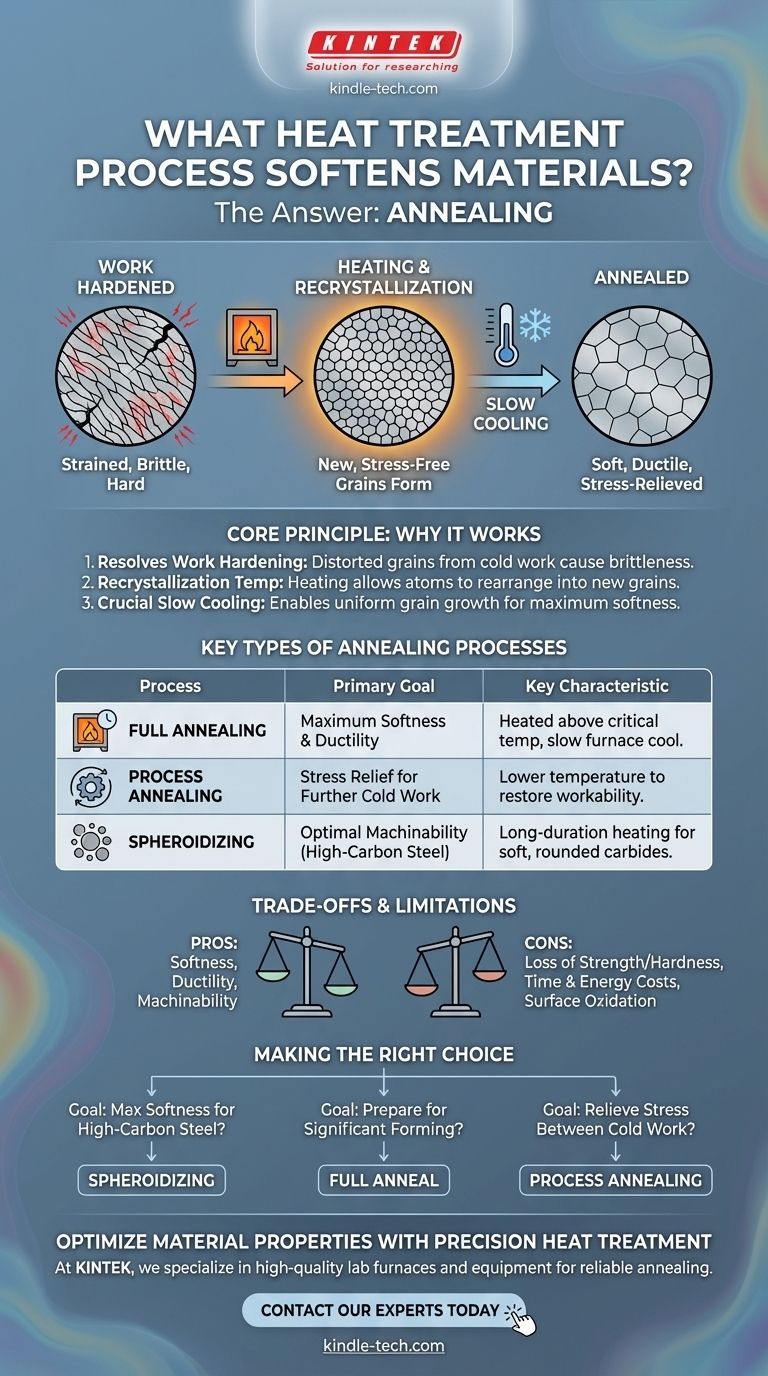

The Core Principle: Why Annealing Works

To understand annealing, you must first understand the problem it solves. Mechanical processes like bending, rolling, or drawing a material fundamentally change its internal grain structure, making it harder but also more brittle.

The Problem of Work Hardening

As a metal is cold-worked, its internal crystalline structure (its "grains") becomes distorted and strained. This process, known as work hardening or strain hardening, increases the material's hardness and strength but severely reduces its ductility, making it prone to cracking if further work is attempted.

Reaching the Recrystallization Temperature

Annealing works by providing thermal energy to the material. When heated above its recrystallization temperature, the atoms have enough energy to rearrange themselves. At this point, new, strain-free grains begin to form, replacing the old, deformed ones created during work hardening.

The Critical Role of Slow Cooling

The final and most crucial step is slow cooling. By cooling the material very slowly (often by simply turning off the furnace and letting it cool with the part inside), the newly formed grains can grow in a uniform, low-stress state. This results in the softest, most ductile microstructure possible. A rapid cool, by contrast, would lock in a different, harder structure.

Key Types of Annealing Processes

The term "annealing" covers several specific processes, each tailored to a different material or desired outcome.

Full Annealing

This is the most common process, where the material is heated above its critical transformation temperature and then cooled very slowly in the furnace. It results in a coarse grain structure that delivers maximum softness and ductility, making the material ideal for extensive plastic deformation.

Process Annealing

Also known as stress-relief annealing, this is a lower-temperature process performed on a work-hardened part. Its goal is to relieve internal stresses and restore some ductility so that further cold working can be done without fracturing the material. It is often performed between manufacturing stages.

Spheroidizing

This specialized, long-duration process is used on high-carbon steels. By holding the steel just below its lower critical temperature for an extended period, the hard carbide structures are transformed into small, rounded globules. This produces the softest possible state for these steels, dramatically improving their machinability.

Understanding the Trade-offs and Limitations

While essential, annealing is not without its practical considerations. It represents a trade-off between a material's properties and manufacturing costs.

Loss of Strength and Hardness

The primary outcome of annealing is a softer, more ductile material. This inherently means you are sacrificing strength and hardness. For many final applications, the part will need to undergo a subsequent hardening heat treatment to regain the necessary strength.

Time and Energy Costs

Annealing, particularly the slow furnace-cooling step, is a time-consuming and energy-intensive process. This directly translates to higher production costs and longer lead times for manufacturing a component.

Potential for Surface Oxidation

Heating metals to high temperatures can cause a layer of oxide, or "scale," to form on the surface. This scale often needs to be removed through processes like sandblasting or acid pickling, adding another step and cost to the manufacturing cycle.

Making the Right Choice for Your Goal

Selecting the correct annealing process depends entirely on the material you are using and what you need to achieve in your manufacturing process.

- If your primary focus is maximum softness and machinability for high-carbon steel: Spheroidizing is the most effective process to prepare the material for cutting and shaping.

- If your primary focus is preparing a raw material for significant forming or bending: A full anneal will provide the high level of ductility required to prevent cracking during severe deformation.

- If your primary focus is relieving stress between cold-working steps: Process or stress-relief annealing is the more efficient and targeted solution to restore workability without a full microstructural reset.

Ultimately, selecting the right annealing process is about precisely controlling a material's internal structure to match the demands of your manufacturing process and final application.

Summary Table:

| Process | Primary Goal | Key Characteristic |

|---|---|---|

| Full Annealing | Maximum Softness & Ductility | Heated above critical temperature, then slow furnace cool. |

| Process Annealing | Stress Relief for Further Cold Work | Lower temperature process to restore workability. |

| Spheroidizing | Optimal Machinability for High-Carbon Steel | Long-duration heating to form soft, rounded carbides. |

Ready to optimize your material properties with precision heat treatment?

At KINTEK, we specialize in supplying the high-quality lab furnaces and equipment needed for reliable annealing processes. Whether you're working with metals for R&D or production, our solutions help you achieve the perfect balance of softness, ductility, and stress relief.

Let's discuss your application. Contact our experts today to find the right furnace for your annealing needs.

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Multi-zone Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How does the sample size affect the needed accuracy of the measurement? Optimize Your Data Quality

- What role does a magnetic stirrer play in the formulation of Palladium/Graphene slurry for electrode fabrication?

- What are the different deposition techniques? A Guide to PVD, CVD, ALD, and More

- What are the risk and protective factors of CVD? Take Control of Your Heart Health Today

- Why magnets are placed behind the target in sputtering? To Trap Electrons for Faster, Purer Coatings

- What is the difference between biomass and biomass energy? Unlock the Power of Renewable Resources

- What products are manufactured with titanium? The Ultimate Guide to High-Performance Materials

- Which method do you prefer to synthesis huge amount of nanoparticles? Scaling Industrial Production