Tungsten is a critical material for industries that demand extreme performance, including construction, metalworking, mining, and high-temperature manufacturing. Its applications range from creating ultra-hard cutting tools and drills to components for vacuum furnaces used in coating and annealing processes.

Tungsten's industrial value is not based on a single application, but on two distinct and powerful properties: its exceptionally high melting point and its ability to form compounds of extreme hardness. Understanding which property is being leveraged is key to understanding its role in any given industry.

Why Tungsten's Heat Resistance is Unmatched

Tungsten's most famous characteristic is its resistance to heat. This property makes it essential for applications where other metals would simply melt or deform.

The Highest Melting Point of Any Metal

With a melting point of 3,422 °C (6,192 °F), tungsten stands alone among metals. This allows it to remain solid and stable in environments that are destructive to virtually everything else.

Use in High-Temperature Furnaces

This thermal stability is why tungsten is used to make components like "tungsten boats." These are containers used within vacuum coating, sintering, and annealing furnaces, where they hold other materials being processed at extreme temperatures.

The Power of Tungsten Carbide

While pure tungsten is valued for heat, it is rarely used for structural applications due to its brittleness. When combined with carbon, however, it transforms into one of the hardest materials made by man: tungsten carbide.

Creating Materials Harder Than Steel

Tungsten carbide is a ceramic-metal composite, not a pure metal. Small tungsten carbide particles are "cemented" together with a metallic binder (often cobalt), creating a material that approaches the hardness of diamond.

Revolutionizing Cutting, Drilling, and Construction

This incredible hardness and wear resistance make tungsten carbide the material of choice for the tips of cutting tools, drill bits, and mining equipment. Industries like construction, manufacturing, and oil and gas rely on it to cut through rock and metal efficiently.

A Key Ingredient in High-Speed Steel

Before the widespread use of carbides, tungsten was a critical alloying agent in high-speed steel. Adding tungsten to steel dramatically increases its hardness and ability to retain a sharp edge at the high temperatures generated by machining.

Understanding the Trade-offs

Despite its powerful advantages, tungsten is not a universal solution. Its unique properties come with practical challenges that limit its use.

The Brittleness of Pure Tungsten

In its pure form, tungsten is quite brittle at room temperature and can be difficult to work with. This is why it is often used in composites (like carbide) or as an alloying element rather than as a primary structural material.

The Density and Weight Factor

Tungsten is one of the densest elements available, nearly twice as dense as lead. While this is an advantage for some niche applications (like counterweights in the ship or aerospace industry), its weight can be a significant drawback elsewhere.

Cost and Machining Difficulty

Tungsten's extreme hardness makes it very difficult and expensive to machine and fabricate. This high processing cost means it is typically reserved for applications where its unique performance characteristics are absolutely necessary.

Making the Right Choice for Your Goal

Selecting tungsten is about targeting a specific, extreme performance requirement that other materials cannot meet.

- If your primary focus is high-temperature stability: Pure tungsten or tungsten alloys are the definitive choice for furnace components, heating elements, and evaporation sources.

- If your primary focus is hardness and wear resistance: Tungsten carbide is the industry standard for cutting, drilling, and abrasion-facing tools.

- If your primary focus is high density in a small volume: Pure tungsten is an excellent material for counterweights, radiation shielding, and other specialized applications where mass is critical.

Ultimately, tungsten's role is to solve problems at the very edge of material science and engineering.

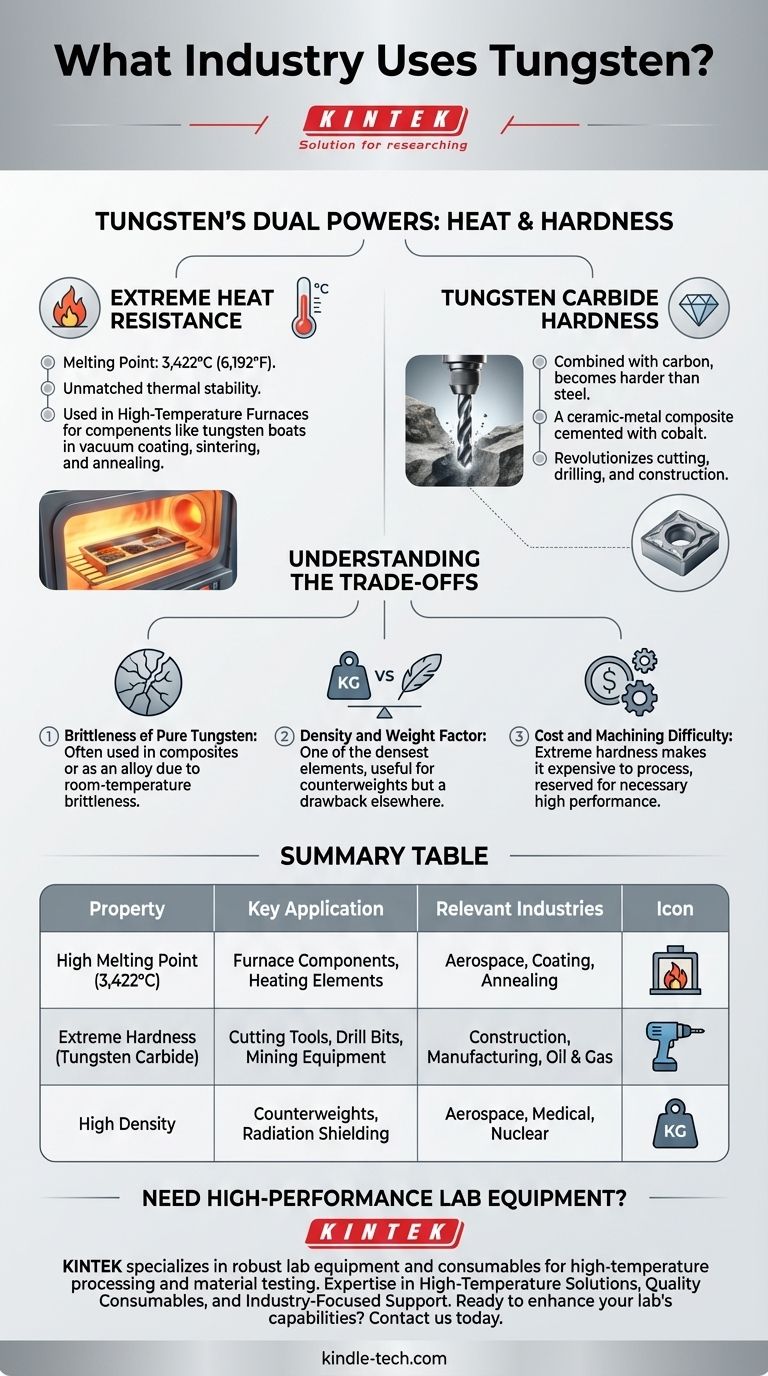

Summary Table:

| Property | Key Application | Relevant Industries |

|---|---|---|

| High Melting Point (3,422°C) | Furnace Components, Heating Elements | Aerospace, Coating, Annealing |

| Extreme Hardness (as Tungsten Carbide) | Cutting Tools, Drill Bits, Mining Equipment | Construction, Manufacturing, Oil & Gas |

| High Density | Counterweights, Radiation Shielding | Aerospace, Medical, Nuclear |

Need High-Performance Lab Equipment for Your Tungsten Applications?

KINTEK specializes in providing robust lab equipment and consumables tailored for industries that rely on high-temperature processing and material testing. Whether you're working with tungsten components for furnace systems or require tools for handling advanced materials, our solutions ensure precision, durability, and efficiency.

Why Choose KINTEK?

- Expertise in High-Temperature Solutions: From vacuum furnaces to sintering systems, we support processes that demand tungsten's extreme heat resistance.

- Quality Consumables: Access reliable tungsten boats, crucibles, and other lab essentials designed for longevity and performance.

- Industry-Focused Support: We serve laboratories in metalworking, research, and manufacturing, helping you achieve consistent, high-quality results.

Ready to enhance your lab's capabilities? Contact us today to discuss your specific needs and discover how KINTEK can empower your innovation.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Freeze Dryer for Lab Use

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why is a high-purity alumina lining required for high-temperature tube furnaces? Ensure Accurate Biomass Research

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- How do you clean a tube furnace tube? A Step-by-Step Guide to Safe and Effective Cleaning

- What are the advantages of using an alumina liner in a tube furnace for biomass combustion corrosion simulations?

- What tube is used for tubular furnace? Choose the Right Material for Temperature & Atmosphere