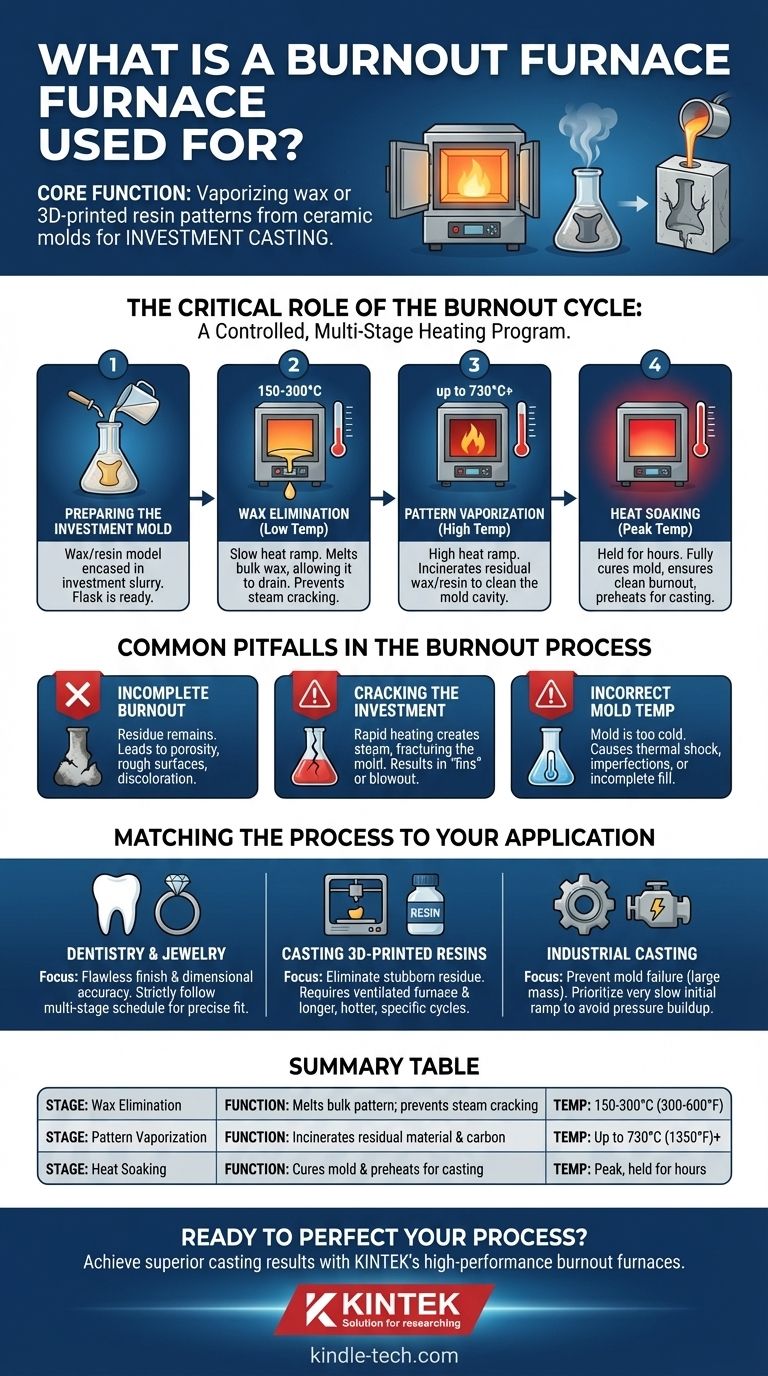

At its core, a burnout furnace is a high-temperature oven used to completely vaporize wax or 3D-printed resin patterns from a ceramic mold. This is the central step in a process called "investment casting" or "lost-wax casting." The furnace executes a precise, multi-stage heating program called a burnout cycle, which creates a perfect, hollow cavity inside the mold, ready to be filled with molten metal.

The true purpose of a burnout furnace is not just to melt a pattern. It is to execute a controlled, time-and-temperature sequence that simultaneously eliminates the pattern without a trace and thermally prepares the mold to receive molten metal without cracking or causing defects.

The Critical Role of the Burnout Cycle

The success of a dental crown, a piece of jewelry, or a precision industrial part often hinges on the flawless execution of the burnout cycle. The entire process is a carefully orchestrated thermal event.

Stage 1: Preparing the Investment Mold

Before the furnace is even used, a wax or resin model of the final part is encased in a plaster-like slurry called investment. Once this investment sets hard, the entire flask is placed into the burnout furnace.

Stage 2: Wax Elimination (Low Temperature)

The furnace begins with a slow and steady temperature increase, typically to around 150-300°C (300-600°F).

The goal of this initial stage is to melt the bulk of the wax, allowing it to drain from the mold. Ramping the temperature too quickly here would turn trapped moisture into steam, cracking the investment.

Stage 3: Pattern Vaporization (High Temperature)

After the initial phase, the temperature is ramped up significantly higher, often to a peak of 730°C (1350°F) or more, depending on the material.

This high-heat stage is what truly defines the "burnout." It incinerates and vaporizes any residual wax, resin, or carbon residue left inside the mold cavity. A clean mold is non-negotiable for a clean casting.

Stage 4: Heat Soaking (Peak Temperature)

The furnace holds the mold at its peak temperature for several hours in a phase called "heat soaking."

This critical step does two things: it ensures every last molecule of the pattern has been eliminated, and it fully cures and strengthens the investment mold. It also brings the mold itself to the optimal temperature for casting, which prevents the molten metal from cooling too quickly when it's poured.

Common Pitfalls in the Burnout Process

The burnout cycle is a process of precision. Deviating from the correct procedure introduces flaws that can ruin the final product.

Incomplete Burnout

If the furnace doesn't reach the right temperature or isn't held there long enough, microscopic carbon residue will remain in the mold. This leads to porosity, rough surfaces, and discoloration in the final metal casting.

Cracking the Investment

Heating the mold too rapidly, especially in the initial low-temperature stage, is the most common cause of failure. The rapid expansion of steam creates fractures in the investment, which will be filled with metal, resulting in unwanted "fins" or a complete blowout.

Incorrect Mold Temperature

Failing to heat-soak the mold properly means it will be too cold when the molten metal is introduced. This thermal shock can cause surface imperfections or cause the metal to solidify before it fills the entire cavity, resulting in an incomplete part.

Matching the Process to Your Application

Your final goal dictates how you approach the burnout cycle. Each application has a unique point of sensitivity.

-

If your primary focus is dentistry or jewelry: Your goal is flawless surface finish and dimensional accuracy. You must strictly follow the multi-stage burnout schedule recommended by the investment manufacturer, as even minor deviations can compromise the fit or finish.

-

If your primary focus is casting 3D-printed resins: Your main challenge is eliminating the stubborn residue and ash that resins can produce. You need a well-ventilated furnace and a longer, often hotter, burnout cycle specifically designed for "castable" resins to ensure a clean mold cavity.

-

If your primary focus is large-scale industrial casting: Your greatest risk is mold failure due to the large mass. Prioritize a very slow and gradual initial temperature ramp to allow moisture and wax to escape without building up destructive pressure within the investment.

Ultimately, mastering the burnout furnace is mastering the foundation of a perfect casting.

Summary Table:

| Burnout Stage | Key Function | Typical Temperature Range |

|---|---|---|

| Wax Elimination | Melts bulk pattern material; prevents steam cracking | 150-300°C (300-600°F) |

| Pattern Vaporization | Incinerates residual wax/resin and carbon residue | Up to 730°C (1350°F) or higher |

| Heat Soaking | Cures the mold & preheats it for casting | Peak temperature held for several hours |

Ready to perfect your investment casting process? A precise burnout cycle is the key to flawless jewelry, dental prosthetics, and industrial parts. KINTEK specializes in high-performance burnout furnaces designed for your specific application, ensuring complete pattern elimination and optimal mold preparation. Contact our experts today to find the ideal furnace for your lab's needs and achieve superior casting results.

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

People Also Ask

- What are the uses of ceramics in dentistry? Achieve Lifelike, Durable Restorations

- How are Dental Press Furnaces used with modern dental technologies? Optimize Your CAD/CAM Digital Workflow

- What is the sintering temperature of zirconia? Achieve Optimal Strength and Aesthetics

- What can all-ceramic restorations be used for? Complete Guide to Modern Dental Solutions

- What is the effect of high speed sintering on zirconia? Dramatically Faster Cycles with Critical Trade-offs

- How do some modern press furnaces mitigate problems related to pressing time? Achieve Consistent, Error-Free Dental Pressing

- What are the different types of temperature calibration systems used in porcelain furnaces? Ensure Precision for Every Ceramic Type

- What is a porcelain furnace in dentistry? The Key to Creating Strong, Aesthetic Dental Restorations