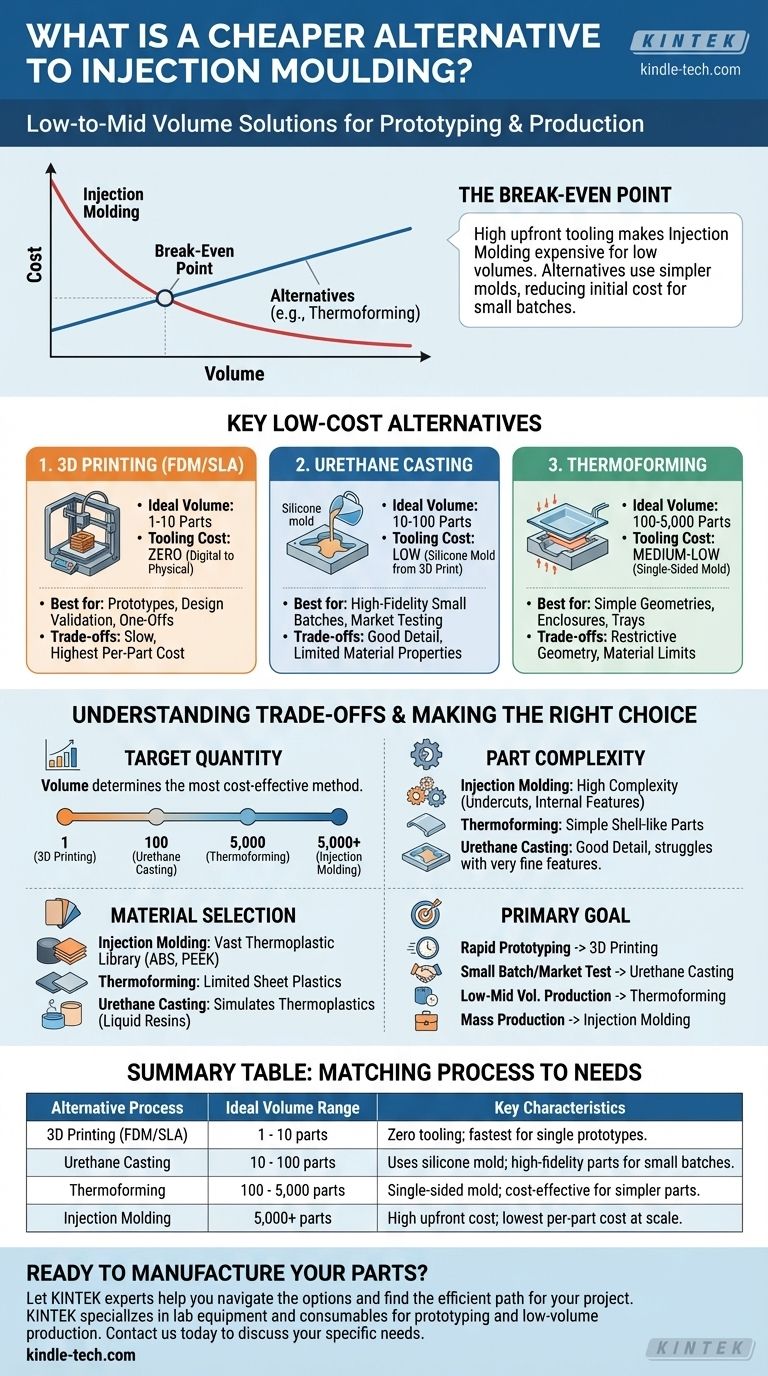

For low-to-mid volume production, thermoforming is a primary low-cost alternative to injection molding. Other key methods, particularly for prototyping and initial runs, include 3D printing and urethane casting. The best choice is not universal; it depends entirely on your required production volume, part complexity, and material properties.

The high cost of injection molding is rooted in the initial tooling, not the individual parts. Cheaper alternatives drastically reduce this upfront investment by using simpler, less durable molds, making them ideal for lower volume production where the high per-part cost is acceptable.

Why Injection Molding Is The Benchmark (And When It's Not)

To understand the alternatives, you must first understand why injection molding is both the gold standard for mass production and often prohibitive for smaller projects. The entire cost structure revolves around the mold itself.

The High Cost of Precision Tooling

Injection molds are masterpieces of engineering. They are typically machined from steel or aluminum, must withstand immense pressure and temperature, and often feature complex internal channels for cooling and mechanisms for ejecting parts.

This complexity means the upfront tooling cost is significant, frequently ranging from $10,000 to over $100,000, depending on the part's size and intricacy.

The Power of Scale: Low Per-Part Cost

The high initial investment is justified by an extremely low per-part cost at scale. Once the mold is created and installed, it can produce hundreds of thousands or even millions of parts.

The cycle time is incredibly fast—often just a matter of seconds per part—and material waste is minimal. For high-volume production, no other process can compete on per-part price.

The Break-Even Point

This creates a break-even point. Below a certain quantity of parts, the high tooling cost makes injection molding uneconomical. Above that point, the low per-part cost makes it the cheapest method available. The alternatives exist to serve the needs below that break-even volume.

Key Low-Cost Alternatives Explored

If your project falls below the injection molding break-even point, several processes offer a more financially viable path forward. Each has a distinct sweet spot based on volume and part type.

Thermoforming: For Simpler Geometries

As noted, thermoforming is an excellent alternative for parts with relatively simple designs, such as enclosures, trays, containers, or large panels.

The process involves heating a sheet of plastic until it is pliable, then stretching it over a single-sided mold using vacuum or pressure. Because the mold is single-sided and experiences much lower stress, it can be made faster and cheaper than an injection mold.

Urethane Casting: For High-Fidelity Small Batches

Urethane casting is the ideal bridge between a single prototype and low-volume production (typically 10-100 units).

The process begins by 3D printing a high-quality "master pattern" of your part. A flexible silicone mold is then cast around this pattern. Once cured, the silicone mold can be used to cast dozens of high-fidelity parts using liquid polyurethane resins that closely mimic production plastics.

3D Printing (FDM/SLA): For Prototypes and Ultra-Low Volume

For one-off parts, design validation, and functional testing, nothing beats 3D printing. It requires zero tooling, going directly from a digital file to a physical object.

While it is the fastest way to get a single part in hand, it is also the slowest and most expensive process on a per-part basis, making it unsuitable for even small production runs.

Understanding the Trade-offs

Choosing a manufacturing process is a balancing act. A lower upfront cost almost always comes with compromises in other areas.

Cost vs. Volume: The Critical Spectrum

The most important factor is your target quantity. A simple mental model is:

- 1-10 parts: 3D Printing

- 10-100 parts: Urethane Casting

- 100-5,000 parts: Thermoforming (for simple parts)

- 5,000+ parts: Injection Molding

These ranges are estimates, but they provide a clear framework for where each process delivers the most value.

Part Complexity and Geometry

Injection molding allows for immense geometric freedom, including complex internal features, screw bosses, and undercuts.

Thermoforming is much more restrictive. It is best for shell-like parts where one side is detailed and the other is relatively simple. Deep draws and sharp internal corners can be challenging. Urethane casting offers good detail but can struggle with the very fine features that injection molding handles with ease.

Material Selection

Injection molding supports a vast library of production thermoplastics, from common ABS and Polypropylene to high-performance PEEK.

Thermoforming is limited to plastics available in sheet form. Urethane casting uses two-part liquid resins that simulate, but are not identical to, their thermoplastic counterparts. This can be a critical distinction for final product performance.

Making the Right Choice for Your Project

Evaluate your immediate goal to select the most efficient and cost-effective manufacturing process.

- If your primary focus is rapid prototyping and design validation: Choose 3D printing for its unparalleled speed and zero tooling cost.

- If your primary focus is producing a small batch (10-100 units) for market testing or sales demos: Urethane casting provides the best balance of high-quality finish and low tooling investment.

- If your primary focus is low-to-mid volume production (100-5,000 units) of simpler parts like covers or trays: Thermoforming is your most cost-effective production solution.

- If your primary focus is mass production (5,000+ units) with the lowest possible per-part cost: Investing in injection mold tooling is the correct long-term financial decision.

By matching the manufacturing process to your specific volume and complexity needs, you can avoid unnecessary costs and bring your product to market efficiently.

Summary Table:

| Alternative Process | Ideal Volume Range | Key Characteristics |

|---|---|---|

| 3D Printing (FDM/SLA) | 1 - 10 parts | Zero tooling cost; fastest for single prototypes. |

| Urethane Casting | 10 - 100 parts | Uses a silicone mold from a 3D-printed master; high-fidelity parts. |

| Thermoforming | 100 - 5,000 parts | Single-sided, low-cost mold; ideal for simpler geometries like enclosures. |

| Injection Molding | 5,000+ parts | High upfront tooling cost; lowest per-part cost at high volumes. |

Ready to Manufacture Your Parts?

Choosing the right process is critical for managing costs and meeting production goals. KINTEK specializes in providing the lab equipment and consumables necessary for prototyping and low-volume production, including solutions for material testing and preparation.

Let our experts help you navigate the options and find the most efficient path for your project.

Contact us today to discuss your specific needs and how we can support your laboratory's success.

Visual Guide

Related Products

- CVD Diamond Domes for Industrial and Scientific Applications

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Custom PTFE Teflon Parts Manufacturer for Hollow Etching Flower Basket ITO FTO Developing Glue Removal

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

People Also Ask

- What are the principles of physical vapour deposition? A Guide to Vacuum-Based Thin Film Coating

- How does catalytic pyrolysis work? Unlock Higher Yields of Valuable Fuels and Chemicals

- What role does the right ULT freezer play in a lab's success? Securing Your Most Valuable Samples

- What is the demand for synthetic diamonds? Rising Popularity for Ethical & Affordable Gems

- Why is it necessary to encapsulate alloy samples? Ensure Purity in High-Temperature Equilibrium Heat Treatment

- What role does a reciprocating shaker play in fungal mycelium cultivation? Boost Your Biomass Pretreatment Efficiency

- What protective roles do Sealing Gaskets and Support Grids play in oil-water separation? Ensure High-Pressure Integrity

- What factors should be considered when selecting a material for high temperature applications? A Guide to Long-Term Performance