At its core, a dental ceramic furnace is a specialized, high-temperature oven used by dental technicians to fabricate ceramic dental restorations like crowns, bridges, veneers, and inlays. This equipment uses precisely controlled heating cycles to process ceramic materials, transforming them from a chalky or powdered state into the hard, aesthetic, and durable final product that can be placed in a patient's mouth.

A dental furnace is not simply an oven; it is a precision instrument. Its primary role is to execute highly specific time-and-temperature programs that are critical for achieving the required strength, fit, and aesthetics of modern dental materials like zirconia and porcelain.

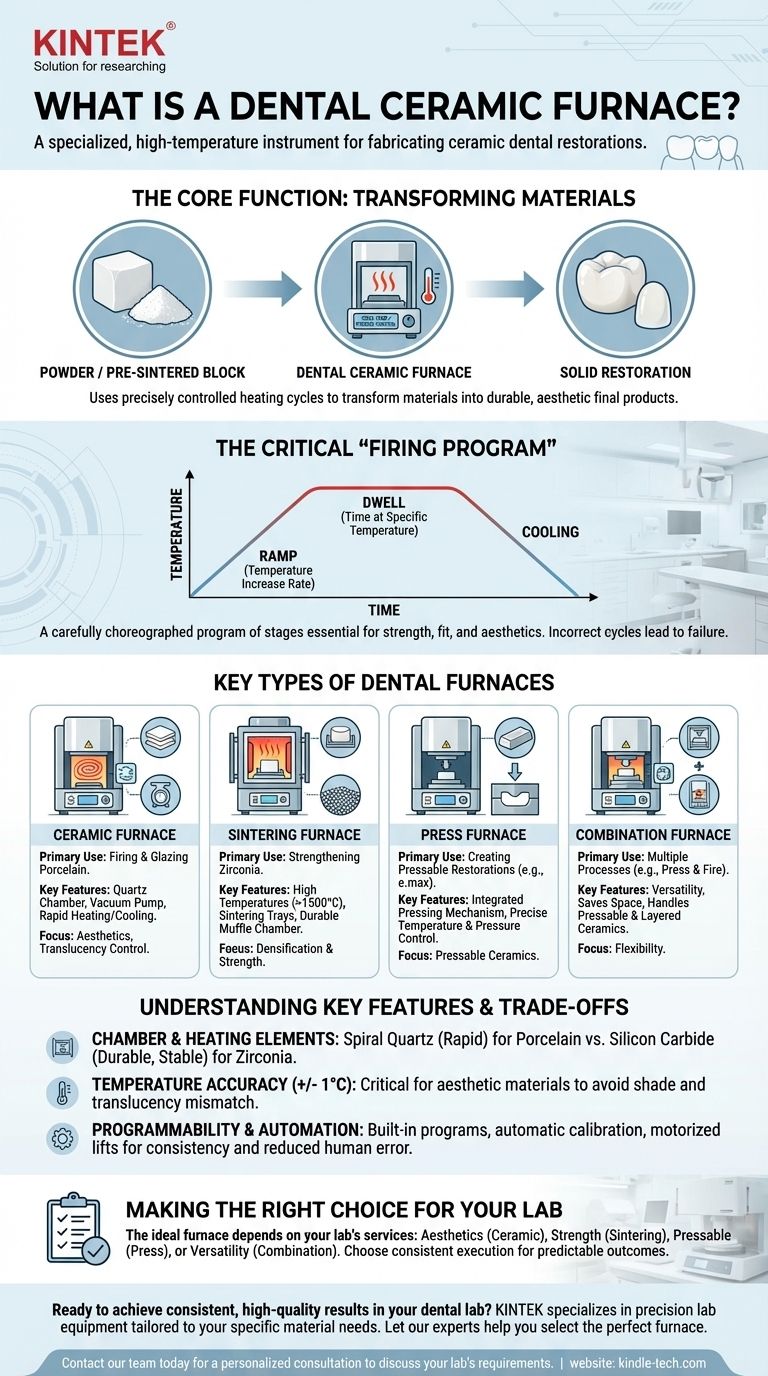

The Core Function: Transforming Materials with Precision Heat

The fundamental purpose of a dental furnace is to create a controlled environment where ceramic materials can undergo physical and chemical changes. This process, broadly known as "firing," is what gives a restoration its final properties.

From Powder or Ingot to Solid Restoration

Dental technicians start with materials like zirconia blocks in a pre-sintered state or porcelain powders. The furnace applies a specific heating cycle, causing the particles to bond and densify into a solid, non-porous structure. This process is essential for the material to gain its strength and durability.

The Critical "Firing Program"

A firing cycle is not just about reaching a peak temperature. It is a carefully choreographed program consisting of multiple stages:

- Ramp: The rate at which the temperature increases.

- Dwell: The amount of time the furnace holds at a specific temperature.

Different materials and processes (e.g., sintering, glazing, pressing) require unique programs. Incorrect ramps or dwells can lead to internal stress, cracks, poor aesthetics, or a complete failure of the restoration.

Uniform Heating for Predictable Results

To prevent warping or cracking, the heat inside the furnace chamber must be completely uniform. This is achieved through the strategic placement of high-quality heating elements, such as silicon carbide, along the chamber walls. This ensures the entire restoration heats and cools at the same rate, guaranteeing a predictable and accurate fit.

Key Types of Dental Furnaces

The term "dental furnace" is a broad category. The specific type you need is dictated entirely by the material you are working with.

The Ceramic Furnace (For Firing & Glazing)

This is the classic furnace for building up porcelain restorations. Technicians apply layers of porcelain powder to a core and fire it after each layer. These furnaces often feature a spiral quartz chamber, which heats and cools very quickly, and a vacuum pump to remove air and create dense, bubble-free porcelain. They are optimized for precision temperature control for aesthetic results.

The Sintering Furnace (For Zirconia)

Zirconia restorations are milled from a pre-sintered block and must then be "sintered" to reach their full strength. This requires a furnace capable of reaching very high temperatures (often over 1500°C) and holding them for extended periods. These furnaces use sintering trays and specialized beads to support the restorations as they shrink significantly during the cycle.

The Press Furnace (For Pressable Ceramics)

Materials like lithium disilicate (e.g., e.max) come in small ingots. A press furnace heats the ingot until it becomes molten and then uses a plunger to "press" the liquid ceramic into a mold. These units combine a high-precision furnace with a motorized pressing mechanism.

The Combination Furnace

Some advanced models are designed as combination units, capable of functioning as both a press furnace and a standard ceramic furnace. This provides versatility for labs that work with both pressable and layered ceramic systems, saving space and cost.

Understanding the Trade-offs and Key Features

When evaluating a furnace, several features directly impact workflow and clinical outcomes.

Chamber and Heating Elements

A spiral quartz chamber allows for rapid heating and cooling, ideal for the multiple, quick cycles needed for porcelain layering. For the sustained, high-heat environment of zirconia sintering, more robust muffle chambers with silicon carbide heating elements are required for their durability and stable heat output.

Temperature Accuracy

High-end furnaces boast an accuracy of +/- 1°C. This is not a luxury; it is a clinical necessity. For aesthetic materials, a deviation of just a few degrees can dramatically alter the shade and translucency of the final crown, leading to a mismatch and requiring a remake.

Programmability and Automation

Modern furnaces come with dozens of built-in programs for common materials and allow for the creation of custom cycles. Features like automatic temperature calibration before each cycle, a smooth motorized lift to prevent jarring the restoration, and USB connectivity for service and updates are all designed to ensure consistency and reduce sources of human error.

Making the Right Choice for Your Lab

The ideal furnace is directly tied to the services your laboratory provides.

- If your primary focus is high-end aesthetics with layered porcelain: A precision ceramic furnace with a quartz chamber and vacuum pump is essential for controlling translucency and shade.

- If your primary focus is high-strength zirconia frameworks and crowns: A dedicated high-temperature sintering furnace is non-negotiable to achieve proper material densification and strength.

- If your primary focus is pressable restorations like lithium disilicate: You require a dedicated press furnace or a combination model with a reliable, programmable pressing mechanism.

- If you are a versatile lab handling multiple material types: A combination press/ceramic furnace offers great value, but you will still need a separate sintering furnace if you plan to work with zirconia.

Ultimately, the right furnace is the one that reliably and consistently executes the precise firing programs your chosen materials demand.

Summary Table:

| Furnace Type | Primary Use | Key Materials | Key Features |

|---|---|---|---|

| Ceramic Furnace | Firing & Glazing Porcelain | Porcelain Powders | Quartz Chamber, Vacuum Pump, Rapid Heating/Cooling |

| Sintering Furnace | Strengthening Zirconia | Zirconia Blocks | High Temperatures (>1500°C), Sintering Trays |

| Press Furnace | Creating Pressable Restorations | Lithium Disilicate (e.max) Ingots | Integrated Pressing Mechanism |

| Combination Furnace | Multiple Processes (e.g., Press & Fire) | Pressable & Layered Ceramics | Versatility, Saves Space |

Ready to achieve consistent, high-quality results in your dental lab?

The right dental furnace is critical for the strength, fit, and aesthetics of every crown, bridge, and veneer you produce. KINTEK specializes in precision lab equipment, including dental ceramic furnaces tailored to your specific material needs—whether you work with zirconia, porcelain, or pressable ceramics.

Let our experts help you select the perfect furnace to enhance your workflow and ensure predictable clinical outcomes.

Contact our team today for a personalized consultation to discuss your lab's requirements.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability