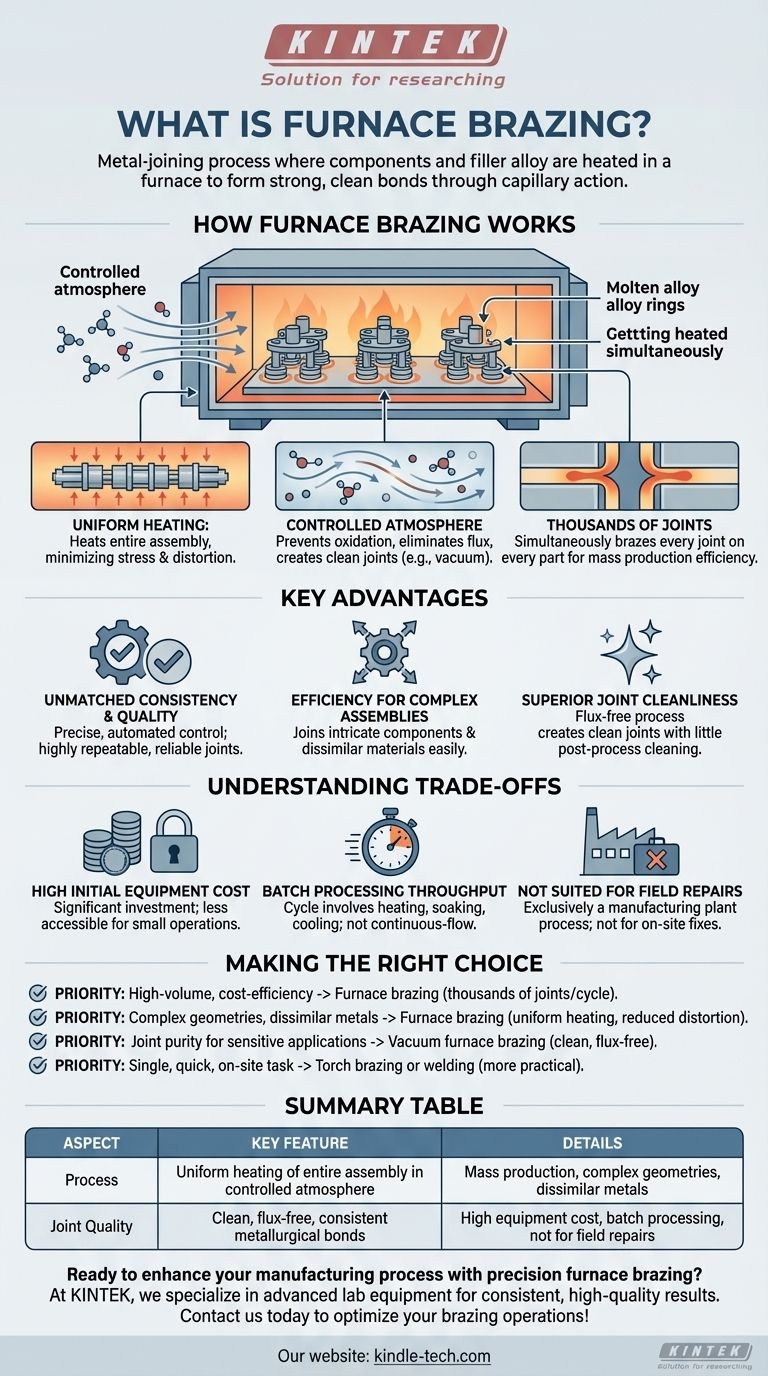

In short, furnace brazing is a metal-joining process where components and a filler metal alloy are placed inside a furnace and heated until the alloy melts. This molten alloy is drawn into the tight-fitting joints of the assembly through capillary action. Upon cooling, the alloy solidifies, creating strong, clean, and consistent metallurgical bonds across the entire assembly.

The core value of furnace brazing is its ability to produce thousands of high-quality, uniform joints simultaneously in a controlled environment. It trades the targeted heat of other methods for the consistency and efficiency of heating an entire assembly at once, making it ideal for mass production and complex components.

How Furnace Brazing Works

Furnace brazing is distinct because it heats the entire workpiece, not just the joint area. This fundamental difference drives its primary benefits and applications.

The Basic Principle of Uniform Heating

An assembly, with the braze alloy pre-placed near the joints, is loaded into a furnace. The furnace temperature is then raised uniformly to a point above the melting point of the braze alloy but below the melting point of the base metals.

This uniform heating minimizes thermal stress and distortion, which is a common risk when heat is applied locally.

The Role of a Controlled Atmosphere

The process is typically performed in a specific atmosphere to prevent the oxidation of the metal surfaces. Vacuum furnace brazing, for example, removes air to create a clean environment.

This eliminates the need for corrosive chemical fluxes that are often required in other brazing methods, resulting in cleaner joints that require little to no post-process cleaning.

Creating Thousands of Joints at Once

Because the entire furnace chamber is at the correct temperature, every joint on every part within that chamber is brazed simultaneously.

This makes the process incredibly efficient and economical for mass production, from automotive components to hydraulic fittings. A single furnace cycle can produce thousands of finished parts.

Key Advantages of the Furnace Method

The decision to use furnace brazing is typically driven by a need for consistency, quality, and efficiency at scale.

Unmatched Consistency and Quality

Precise, automated temperature control ensures every joint is heated and cooled under identical conditions. This results in highly repeatable and reliable joints with minimal voids and excellent mechanical properties.

Efficiency for Complex Assemblies

Furnace brazing excels at joining intricate components or assemblies with multiple joints. It can easily join materials with different melting points or thicknesses, a significant challenge for methods that apply localized heat.

Superior Joint Cleanliness

By eliminating the need for flux, especially in a vacuum environment, the finished parts are free from entrapped flux residues that can cause corrosion or joint failure. The resulting joints are clean and often require no secondary finishing.

Understanding the Trade-offs

While powerful, furnace brazing is not the universal solution for all joining needs. Its strengths are balanced by specific limitations.

High Initial Equipment Cost

Industrial furnaces, particularly vacuum furnaces, represent a significant capital investment. This makes the process less accessible for small-scale operations or hobbyists compared to simpler methods like torch brazing.

Batch Processing Throughput

Furnace brazing is a batch process. A cycle involves loading, heating, soaking at temperature, cooling, and unloading. This cycle time means it is not a continuous-flow operation, which may be a constraint for certain production workflows.

Not Suited for Field Repairs

Due to the reliance on large, stationary equipment, furnace brazing is exclusively a manufacturing plant process. It is completely unsuitable for on-site repairs or applications that require portable joining equipment.

Making the Right Choice for Your Goal

Selecting furnace brazing depends entirely on your project's priorities, scale, and technical requirements.

- If your primary focus is high-volume production and cost-efficiency: Furnace brazing is unmatched for creating thousands of consistent, low-cost joints per cycle.

- If your primary focus is joining complex geometries or dissimilar metals: The uniform heating and precise control of furnace brazing provide superior quality and reduce the risk of distortion.

- If your primary focus is joint purity for sensitive applications: Vacuum furnace brazing produces exceptionally clean, flux-free joints required in the aerospace, medical, and electronics industries.

- If your primary focus is a single, quick, or on-site joining task: A more direct method like torch brazing or welding is a far more practical choice.

Ultimately, furnace brazing is the definitive choice when process control, consistency, and scale are your most critical engineering requirements.

Summary Table:

| Aspect | Key Feature |

|---|---|

| Process | Uniform heating of entire assembly in controlled atmosphere |

| Best For | Mass production, complex geometries, dissimilar metals |

| Joint Quality | Clean, flux-free, consistent metallurgical bonds |

| Limitations | High equipment cost, batch processing, not for field repairs |

Ready to enhance your manufacturing process with precision furnace brazing?

At KINTEK, we specialize in advanced lab equipment and consumables that deliver the consistent, high-quality results your laboratory demands. Our expertise in controlled atmosphere systems ensures your metal-joining projects achieve superior joint integrity and production efficiency.

Whether you're in aerospace, medical, or electronics manufacturing, our solutions are designed to meet your specific needs for clean, reliable brazing results.

Contact us today to discuss how KINTEK can optimize your brazing operations!

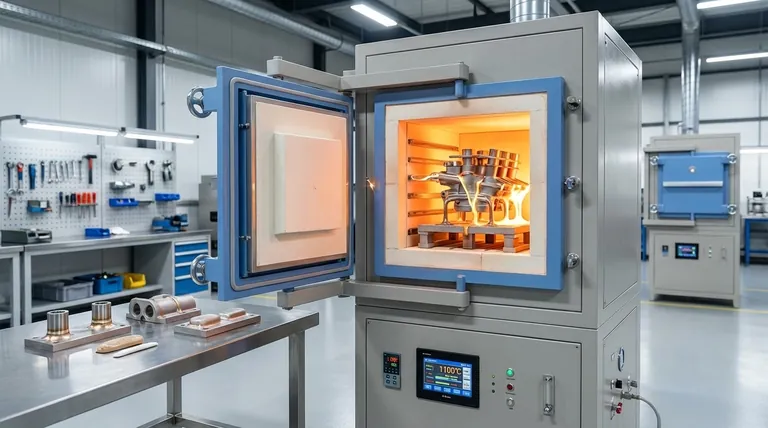

Visual Guide

Related Products

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- Why nitrogen is used in furnace? A Cost-Effective Shield for High-Temperature Processes

- What is meant by inert atmosphere? A Guide to Preventing Oxidation & Ensuring Safety

- How we can develop inert atmosphere for a chemical reaction? Master Precise Atmospheric Control for Your Lab

- Can nitrogen be used for brazing? Key Conditions and Applications Explained

- What provides an inert atmosphere? Achieve Safety and Purity with Nitrogen, Argon, or CO2