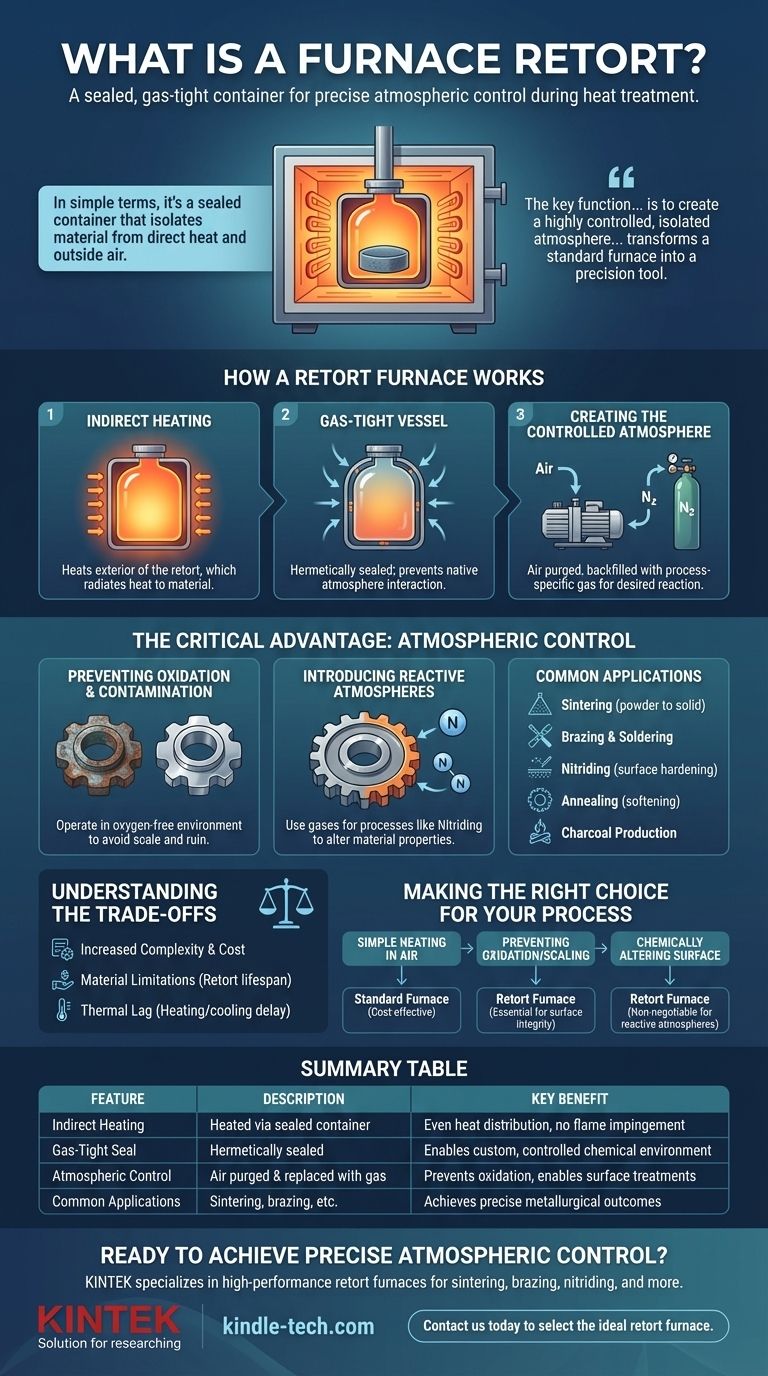

In simple terms, a furnace retort is a sealed, gas-tight container placed inside a furnace. Its purpose is to isolate the material being processed from the direct heat source and the outside air. This separation allows for precise control over the chemical atmosphere surrounding the material during heat treatment, which is critical for many advanced processes.

The key function of a furnace retort is not just to hold material, but to create a highly controlled, isolated atmosphere around it. This transforms a standard furnace into a precision tool for specialized thermal processes where the chemical environment is as critical as the temperature itself.

How a Retort Furnace Works

A retort furnace operates on the principle of indirect heating and atmospheric isolation. Understanding this core concept is key to appreciating its value.

The Principle: Indirect Heating

The furnace's heating elements—either electric resistance heaters or gas burners—do not heat the target material directly. Instead, they heat the exterior of the retort.

The retort, typically made of high-temperature resistant steel or a nickel-based alloy, absorbs this heat and radiates it evenly to the material contained within it.

The Gas-Tight Vessel

The defining feature of the retort is that it is hermetically sealed. This seal prevents the furnace's native atmosphere (or outside air) from interacting with the workpiece.

This design enables operators to create a custom atmosphere inside the retort. Air can be purged and replaced with a specific gas or gas mixture to achieve a desired chemical reaction or to prevent an unwanted one.

Creating the Controlled Atmosphere

Once the material is loaded and the retort is sealed, a vacuum may be pulled to remove all air. Following this, the chamber can be backfilled with a process-specific gas.

For example, a nitrogen-rich atmosphere is used for nitriding, while an inert gas like argon can be used to prevent any chemical changes during heating.

The Critical Advantage: Atmospheric Control

The ability to manipulate the atmosphere is why retort furnaces are essential for certain applications. Without this control, many modern material treatments would be impossible.

Preventing Oxidation and Contamination

The most common use of a controlled atmosphere is to prevent oxidation. At high temperatures, many metals react with oxygen in the air, forming a layer of scale that can ruin the surface finish and dimensional accuracy of a part.

By operating in an oxygen-free environment, materials can be heated and cooled without this degradation. This is often called "bright annealing."

Introducing Reactive Atmospheres

Beyond simple prevention, retort furnaces allow for the introduction of reactive gases to intentionally alter a material's properties.

Processes like nitriding introduce nitrogen to harden the surface of steel. Other processes might use hydrogen or carbon-rich gases to achieve specific metallurgical outcomes.

Common Applications

This level of control makes retort furnaces indispensable for:

- Sintering: Fusing powdered metals together without melting them.

- Brazing & Soldering: Joining metals in a clean, flux-free environment.

- Nitriding: Case-hardening steel surfaces.

- Annealing: Softening metals and relieving internal stresses.

- Charcoal Production: Heating wood in the absence of oxygen.

Understanding the Trade-offs

While powerful, the retort furnace design is not universally necessary and comes with specific considerations.

Increased Complexity and Cost

The need for a high-integrity seal, gas delivery systems, and purging protocols makes a retort furnace more complex and expensive than a simple air-fired furnace. The retort itself is a consumable component that will eventually degrade from thermal cycling.

Material Limitations

The retort is made from specialized, high-temperature alloys that can withstand the extreme conditions. However, even these materials have temperature and lifespan limits, which can constrain the furnace's operational range and increase maintenance costs.

Thermal Lag

Because the heat must first transfer through the retort wall to reach the workpiece, there can be a slight delay in heating and cooling cycles compared to direct-fired furnaces. This is a minor trade-off for the immense benefit of atmospheric control.

Making the Right Choice for Your Process

Choosing whether you need a retort furnace comes down to the chemical requirements of your specific thermal process.

- If your primary focus is simple heating in air: A standard furnace without a retort is more cost-effective and simpler for processes where surface oxidation is acceptable or desired.

- If your primary focus is preventing oxidation or scaling: A retort furnace is essential for maintaining the surface integrity and finish of sensitive materials like stainless steel or copper alloys.

- If your primary focus is chemically altering a material's surface: A retort is non-negotiable for processes like nitriding or carburizing that require a specific, reactive gas atmosphere.

Ultimately, understanding the function of the retort allows you to select not just a heating device, but the precise atmospheric environment required for your process.

Summary Table:

| Feature | Description | Key Benefit |

|---|---|---|

| Indirect Heating | Material is heated via a sealed container (retort) inside the furnace. | Prevents direct flame impingement and ensures even heat distribution. |

| Gas-Tight Seal | The retort is hermetically sealed, isolating the workpiece from the furnace atmosphere. | Enables creation of a custom, controlled chemical environment (e.g., nitrogen, argon). |

| Atmospheric Control | Air is purged and replaced with a specific gas mixture for the process. | Essential for preventing oxidation (bright annealing) or enabling surface treatments (nitriding). |

| Common Applications | Sintering, brazing, annealing, nitriding, charcoal production. | Achieves precise metallurgical outcomes impossible in a standard air atmosphere. |

Ready to Achieve Precise Atmospheric Control in Your Lab?

If your thermal processes require protection from oxidation or a specific reactive gas environment, a retort furnace is the essential solution. KINTEK specializes in high-performance lab equipment, including retort furnaces designed for sintering, brazing, nitriding, and more.

We provide the right equipment to ensure your materials are processed in the perfect atmosphere, guaranteeing superior results and repeatability.

Contact us today to discuss your specific application and let our experts help you select the ideal retort furnace for your laboratory needs.

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vertical Laboratory Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How is a high-temperature calcination furnace utilized in BZY20 Sol-gel? Achieve Pure Cubic Perovskite Phases

- How do high-temperature reaction furnaces control in-situ MMCs? Master Material Precision and Structural Integrity

- What is the difference between pyrolysis combustion and gasification? A Guide to Thermal Conversion Technologies

- What temperature is needed for pyrolysis waste? A Guide to Optimizing Your Waste-to-Value Process

- What are the equipment requirements for loading platinum (Pt) onto composite supports? Precise Stirring for High Dispersion