In essence, a high-temperature furnace is a specialized piece of equipment designed to create a precisely controlled, extremely hot environment. Unlike a conventional oven, its primary purpose is to fundamentally alter the physical or chemical properties of materials through processes like heat treatment, sintering, or elemental analysis, operating at temperatures that can exceed 1750°C.

The critical takeaway is that a high-temperature furnace is not just a heater; it is a sophisticated instrument. Its value lies in its ability to create a highly stable and uniform environment—controlling not only extreme heat but often the atmospheric pressure and composition as well—to achieve specific, repeatable material outcomes.

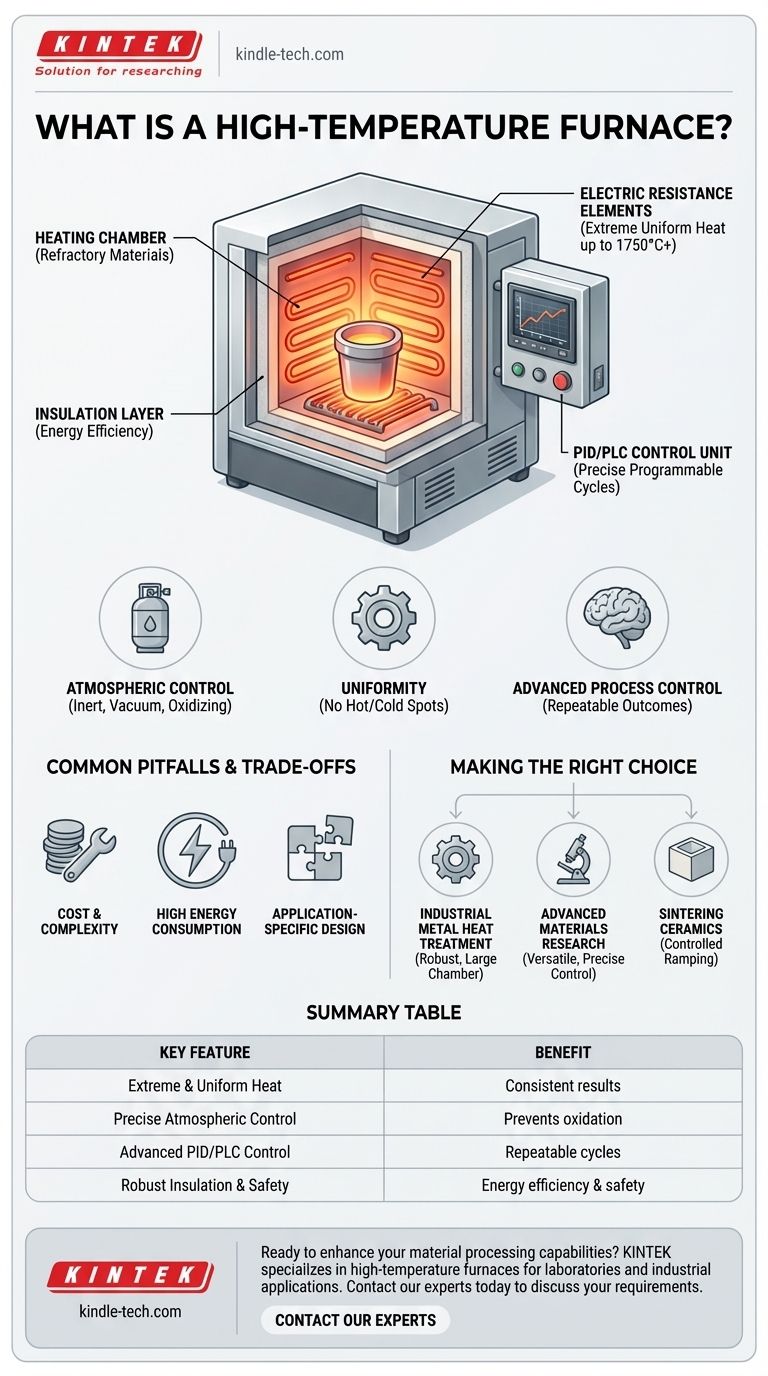

What Defines a High-Temperature Furnace?

To understand these devices, we must look beyond the heat itself and focus on the precision, control, and specialized environments they create.

Extreme and Uniform Heat

The most obvious characteristic is the ability to generate and sustain very high temperatures. This is achieved with powerful heating systems, often using electric resistance elements placed on multiple sides of the chamber.

This multi-sided placement is crucial for ensuring good thermal uniformity, which means the temperature is consistent throughout the entire heating chamber. This prevents hot or cold spots, which is vital for predictable and reliable processing.

Precise Atmospheric Control

Many advanced material processes are sensitive to the gasses in the air, especially oxygen, which can cause unwanted oxidation.

High-temperature furnaces solve this by enabling complete control over the internal atmosphere. They can operate with an inert (non-reactive), reducing (oxygen-removing), or oxidizing atmosphere. Some models, known as vacuum furnaces, use a vacuum system to create a low-pressure environment.

Advanced Process Control

These furnaces are governed by sophisticated control systems. A microprocessor PID (Proportional-Integral-Derivative) controller or an industrial PLC (Programmable Logic Controller) regulates temperature, pressure, and process timing with a high degree of accuracy.

This allows for programmable heating cycles, including specific ramp-up speeds and holding times, which are essential for complex treatments and scientific research.

The Core Components of a High-Temperature Furnace

While designs vary, most high-temperature furnaces are built around a common set of core components that work together to create a stable and safe operating environment.

The Heating Chamber and Insulation

The "hot zone" or inner chamber is built from high-grade refractory materials designed to withstand extreme thermal stress without degrading. This chamber houses the material being processed.

Surrounding the chamber is a thick layer of insulation, which minimizes heat loss, improves energy efficiency, and keeps the exterior of the furnace at a safe temperature.

The Heating System

The most common method for generating heat is through electric resistance elements. However, other specialized methods exist, such as the microwave heating used in certain sintering furnaces for rapid and uniform heating.

The Control and Safety Systems

The electronic control unit is the brain of the furnace. It includes the PID or PLC controller, digital displays for temperature and power, and the user interface, which can be a simple LED readout or a modern touch screen.

Safety is paramount. Features like a door safety switch that cuts power to the heaters when the door is opened and highly integrated interlocks prevent accidents and protect the equipment.

Common Pitfalls and Trade-offs

While incredibly powerful, these instruments come with inherent complexities and considerations that must be understood.

Cost and Complexity

The specialized materials, powerful heating elements, and sophisticated control systems make high-temperature furnaces a significant investment. Their operation and maintenance require more technical expertise than standard equipment.

High Energy Consumption

Achieving and maintaining temperatures well over 1000°C is an energy-intensive process. While modern designs emphasize energy savings through superior insulation, they remain major consumers of electricity.

Application-Specific Design

A furnace designed for vacuum heat treatment of steel is not interchangeable with one designed for ceramic sintering in an oxygen atmosphere. The choice of furnace must be precisely matched to the intended material and process, as the design and components are highly specialized.

Making the Right Choice for Your Goal

Selecting the correct type of high-temperature furnace depends entirely on its intended application.

- If your primary focus is industrial metal heat treatment: Your priority is a robust furnace with excellent temperature uniformity, a large chamber, and repeatable, programmable cycles for hardening or annealing.

- If your primary focus is advanced materials research: You need a highly versatile system with precise control over temperature profiling, vacuum levels, and multiple atmospheric compositions.

- If your primary focus is sintering ceramics or powdered metals: Look for a furnace that excels at controlled temperature ramping and holding, often called a muffle furnace, with the specific atmospheric capabilities your material requires.

Ultimately, these furnaces are foundational tools that enable the innovation and production of the advanced materials that define modern technology.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Extreme & Uniform Heat (up to 1750°C+) | Consistent results, no hot/cold spots |

| Precise Atmospheric Control (Inert, Vacuum, Oxidizing) | Prevents oxidation, enables specific reactions |

| Advanced PID/PLC Control Systems | Repeatable, programmable heating cycles |

| Robust Insulation & Safety Systems | Energy efficiency and operator protection |

Ready to enhance your material processing capabilities? KINTEK specializes in high-temperature furnaces for laboratories and industrial applications. Whether you need precise sintering, heat treatment, or advanced materials research, our expertise ensures you get the right equipment for repeatable, high-quality results. Contact our experts today to discuss your specific requirements and discover how KINTEK can power your innovation.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- Why is a high vacuum oven required for the heat treatment of V-5Cr-5Ti alloys? Protect Material Purity & Performance

- Why is a vacuum environment necessary for sintering ZrC-SiC? Prevent Oxidation and Ensure Phase Purity

- What is the temperature range for quenching? Achieve Perfect Hardness for Your Steel Alloy

- How does a high-temperature heat treatment furnace facilitate solution annealing? Master Alloy Microstructure Control

- What role does a vacuum drying oven play in PEO-RPPO composite membrane fabrication? Optimize Solid Electrolyte Purity

- What are the advantages of brazing? Achieve Superior Joint Integrity for Complex Assemblies

- How is vacuum packing different from normal packing? A Guide to Industrial Vacuum Hardening

- What are the advantages of using an independent internal charging tank in a vertical vacuum distillation furnace?