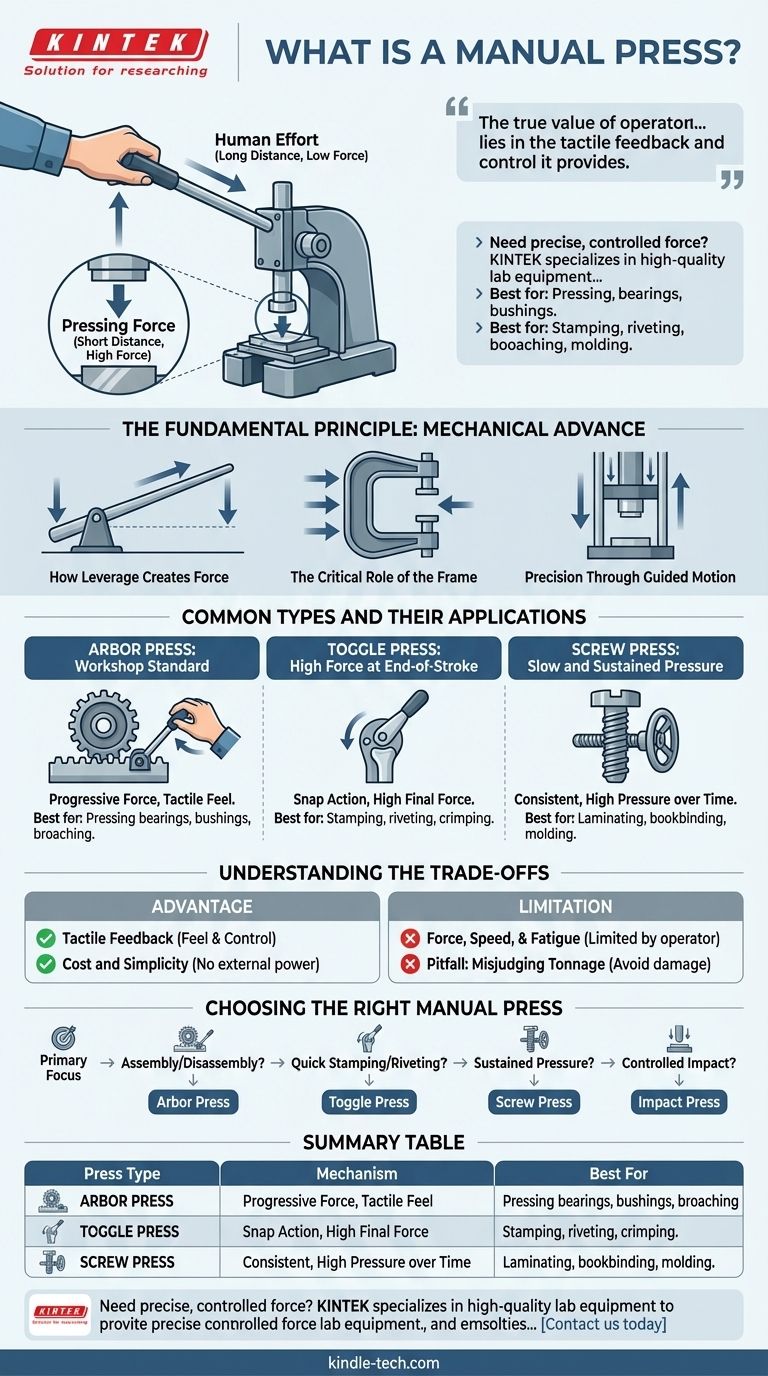

At its core, a manual press is a mechanical device designed to amplify human effort into a significant and controllable pressing force. It uses principles of leverage, such as a long handle, rack and pinion gears, or a screw mechanism, to allow an operator to perform tasks like assembling parts, stamping designs, or bending metal with precision that would be impossible by hand alone.

The true value of a manual press lies not just in the force it generates, but in the tactile feedback and control it provides. It translates an operator's physical input into precise, repeatable pressure, making it an indispensable tool for tasks where feel and accuracy are paramount.

The Fundamental Principle: Mechanical Advantage

A manual press is a classic example of using simple machines to create a powerful output. Understanding how it achieves this is key to using it effectively.

How Leverage Creates Force

A manual press relies on mechanical advantage. By applying a small force over a long distance (pulling a long handle), the machine converts it into a large force applied over a short distance at the tool's point of contact. This is often achieved through a rack and pinion system in an arbor press or a toggle linkage.

The Critical Role of the Frame

The press's rigid frame, typically a C-frame or H-frame design, is essential. It absorbs the immense opposing force generated during a press operation. A strong, non-flexing frame ensures that all the energy is directed into the workpiece and maintains the alignment of the ram.

Precision Through Guided Motion

The moving component of the press, known as the ram or spindle, travels in a precisely guided path. This ensures that force is applied perpendicularly to the work surface, preventing misalignment and guaranteeing repeatable results for every operation.

Common Types and Their Applications

The specific mechanism of a press dictates its best use case. Choosing the right type is critical for achieving the desired outcome.

Arbor Press: The Workshop Standard

The most common type, an arbor press, uses a lever handle connected to a rack-and-pinion gear system. It delivers smooth, linear force that increases progressively as the operator pulls the handle.

This makes it ideal for tasks requiring feel and control, such as pressing bearings into housings, inserting bushings, or broaching keyways. The operator can feel when a part is seating correctly.

Toggle Press: High Force at the End-of-Stroke

A toggle press uses a compound lever system that works like a knee joint. It delivers relatively low force through most of its stroke but achieves an extremely high mechanical advantage in the last few millimeters of travel.

This "snap" action is perfect for quick operations like stamping, riveting, crimping, and light-duty punching where maximum force is needed at a precise final position.

Screw Press: Slow and Sustained Pressure

As the name implies, a screw press uses a large-diameter screw to generate force. Turning the handle or wheel slowly lowers the ram, creating very high, consistent pressure.

This design is best suited for applications that require sustained, even pressure over a period of time, such as laminating, bookbinding, or compressing materials in a mold.

Understanding the Trade-offs

While powerful, manual presses have clear limitations compared to their powered counterparts (hydraulic or pneumatic).

Advantage: Tactile Feedback and Control

The greatest strength of a manual press is the direct connection between the operator and the workpiece. You can feel the force being applied, allowing for subtle adjustments on the fly. This is invaluable when seating sensitive components where too much force could cause damage.

Limitation: Force, Speed, and Fatigue

A manual press is limited by the operator's strength and stamina. It cannot match the sheer tonnage or high cycle rates of a hydraulic press, making it unsuitable for high-volume production or forming very thick materials.

Advantage: Cost and Simplicity

With no motors, pumps, or external power sources, manual presses are significantly less expensive to purchase and maintain. Their simple mechanical design makes them exceptionally reliable and easy to set up and use in any workshop environment.

Pitfall: Misjudging Tonnage

A common mistake is selecting a press with insufficient tonnage for the job. Operations like punching metal require significantly more force than pressing a bearing. Always calculate the required force for your specific material and operation to avoid damaging the press or failing to complete the task.

Choosing the Right Manual Press for Your Task

Your choice of press should be dictated entirely by the nature of the force you need to apply and the task you need to accomplish.

- If your primary focus is assembly and disassembly (like bearings or bushings): An arbor press offers the best combination of progressive force and tactile feedback.

- If your primary focus is quick stamping, punching, or riveting: A toggle press provides the high, end-of-stroke force needed for these forming operations.

- If your primary focus is sustained, even pressure for bonding or forming: A screw press delivers the slow, steady force that is ideal for lamination and clamping tasks.

- If your primary focus is controlled impact for marking or staking: A dedicated impact press (a spring-loaded variant) is designed specifically for this repeatable striking action.

Ultimately, a manual press is a foundational workshop tool that empowers you to apply precise force with unmatched control.

Summary Table:

| Press Type | Mechanism | Best For |

|---|---|---|

| Arbor Press | Rack and Pinion | Pressing bearings, assembly, tasks requiring 'feel' |

| Toggle Press | Toggle Linkage | Stamping, riveting, high force at end-of-stroke |

| Screw Press | Screw Mechanism | Laminating, bookbinding, sustained pressure |

Need precise, controlled force in your lab or workshop? KINTEK specializes in high-quality lab equipment and consumables, including a range of manual presses perfect for your specific application. Our experts can help you select the ideal press for tasks like assembly, stamping, or laminating. Contact us today to enhance your workshop's capabilities with the right tool for the job!

Visual Guide

Related Products

- Manual Lab Heat Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What are the parts of a manual hydraulic press? A Guide to Its Core Components and Operation

- What is the efficiency of a hydraulic press? Harness Unmatched Force Multiplication for Your Lab

- What is the construction of a hydraulic press based on? Unlocking the Power of Pascal's Law

- What is a hydraulic press in simple words? Harness Immense Force for Shaping and Crushing

- What are the failures of a hydraulic press? Prevent Downtime and Ensure Safety in Your Lab