At its core, a muffle furnace for ash analysis is a high-temperature laboratory oven that completely incinerates a sample to determine its inorganic, non-combustible content, known as ash. Its defining feature is a sealed inner chamber, the "muffle," which isolates the sample from direct contact with the heating elements. This design prevents contamination from combustion byproducts, ensuring the final ash measurement is pure and accurate.

The primary purpose of using a muffle furnace is not just to burn a sample, but to do so in a perfectly controlled and isolated environment. This isolation is the cornerstone of obtaining accurate and repeatable ash content data for quality control and material analysis.

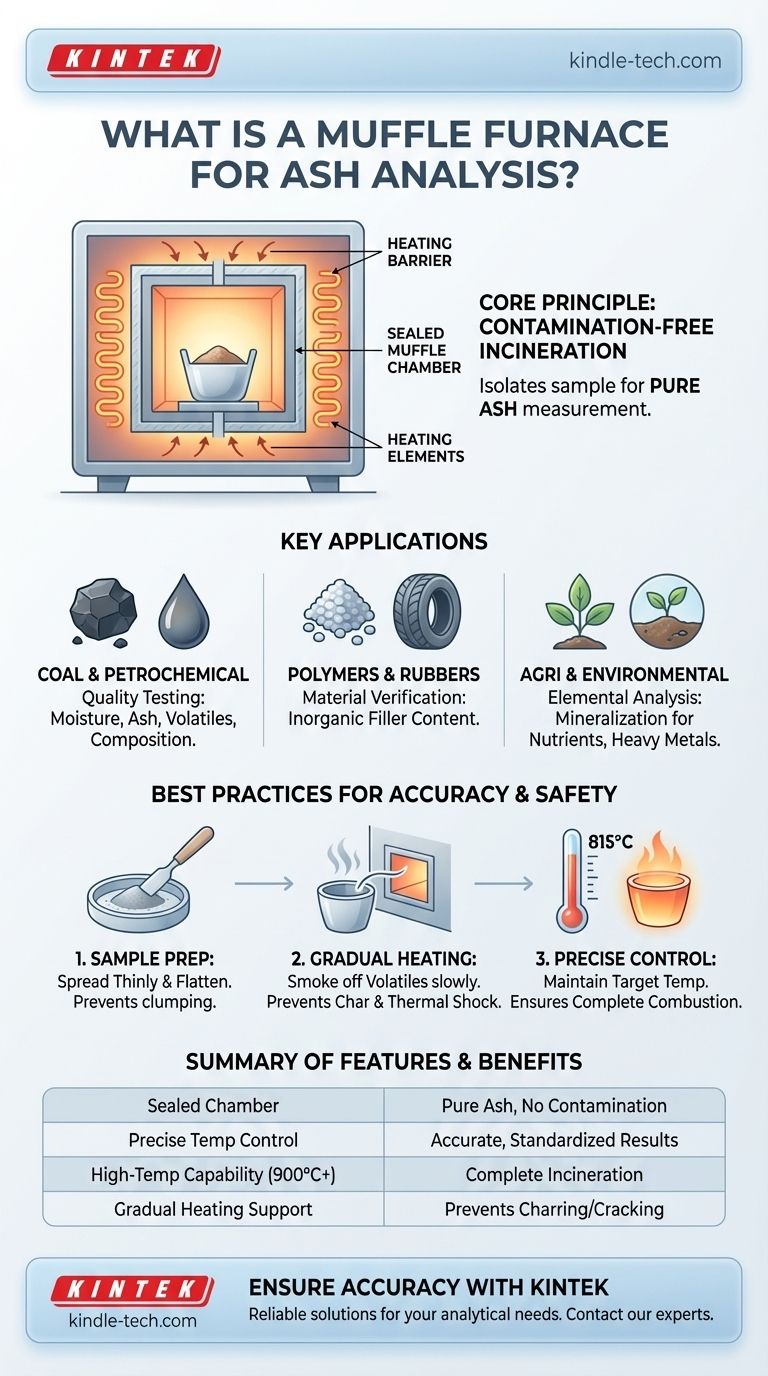

The Principle of Contamination-Free Incineration

A muffle furnace's design is fundamental to its function in analytical testing. It is built around the principle of separating the sample from any potential contaminants.

The Role of the "Muffle"

Historically, furnaces burned fuel that produced ash, soot, and fumes. The "muffle" was developed as a barrier to shield the material being heated from these impurities.

In modern electric furnaces, the muffle chamber isolates the sample from the heating elements, preventing any direct interaction that could alter the sample's composition.

Why Isolation is Critical for Ash Analysis

Ash analysis works by measuring the weight of what is left after all organic material has been burned away.

If any external particles or gases were to settle on the sample during this process, the final weight would be artificially high, leading to incorrect results. The muffle ensures that the only material left in the crucible is the true ash from the original sample.

Achieving Precise Temperatures

Muffle furnaces are designed to reach and maintain very high temperatures, often up to 900°C or more.

Accurate temperature control is critical. For instance, in coal analysis, the sample is burned at a specific temperature, such as 815±15°C, to ensure complete and standardized combustion.

Key Applications in Ash Content Determination

The ability to produce pure ash in a controlled manner makes the muffle furnace indispensable across various industries for quality control and material verification.

Coal and Petrochemical Industries

In coal quality testing, a muffle furnace is used to determine moisture, ash content, and volatile matter. It is also used for analyzing ash composition and its melting point.

Similarly, the petrochemical industry uses it for the analysis of petroleum products, where contamination-free results are essential for meeting regulatory and quality standards.

Polymers, Rubbers, and Composites

The furnace is ideal for determining the ash content of materials that are stable at high temperatures, such as polymers and rubbers.

This process measures the amount of inorganic filler (like silica or calcium carbonate) in the material, which is a key indicator of its grade and performance characteristics.

Agricultural and Environmental Analysis

Muffle furnaces are widely used for the mineralization of plant samples. By burning away the organic matter, scientists can prepare the remaining mineral ash for further elemental analysis to check for nutrient levels or the presence of heavy metals.

Understanding the Trade-offs and Best Practices

While powerful, a muffle furnace's accuracy depends entirely on proper procedure. Rushing the process or preparing samples incorrectly will invalidate the results.

The Risk of Incomplete Combustion

The most common error is failing to burn the sample completely. This leaves behind partially combusted organic material (char), which adds to the final weight and makes the ash content appear higher than it is.

To prevent this, samples must be heated gradually. They should be placed near the furnace mouth first to allow volatile compounds to smoke and burn off slowly before being moved into the hottest part of the furnace.

Sample Preparation is Non-Negotiable

The physical preparation of the sample is a critical step. The sample should be flattened and spread thinly in its crucible (often a porcelain boat).

A thick or clumped sample will not heat uniformly. The outer layer can form a crust, preventing oxygen from reaching the material inside and leading to incomplete combustion.

Gradual Heating Prevents Thermal Shock

Slowly introducing the sample into the hot furnace is not just for the sample's sake. It also prevents thermal shock to the porcelain crucible, which can crack or shatter if its temperature changes too rapidly.

How to Ensure Accurate Ash Analysis Results

To get the most out of this technique, align your procedure with your analytical goal.

- If your primary focus is process validation and QC: Concentrate on maintaining precise temperature control and a contamination-free environment to guarantee repeatable, accurate measurements.

- If your primary focus is material characterization: Use the furnace to determine the inorganic filler content in polymers or rubbers, a critical data point for verifying material specifications.

- If your primary focus is environmental or agricultural testing: Employ the ashing process to mineralize samples, preparing them for subsequent elemental analysis to detect nutrients or contaminants.

Ultimately, mastering the use of a muffle furnace is about controlling every variable to reveal the true inorganic composition of your material.

Summary Table:

| Key Feature | Benefit for Ash Analysis |

|---|---|

| Sealed Muffle Chamber | Prevents contamination from heating elements for pure ash measurement |

| Precise Temperature Control | Ensures complete, standardized combustion (e.g., 815±15°C for coal) |

| High-Temperature Capability | Reaches temperatures up to 900°C+ for complete incineration of organic material |

| Gradual Heating Support | Prevents sample charring and thermal shock to crucibles for accurate results |

Ensure the accuracy of your ash analysis with a reliable muffle furnace from KINTEK.

KINTEK specializes in high-performance lab equipment, including muffle furnaces designed for precise, contamination-free testing. Whether you work in quality control for coal and petrochemicals, need to verify polymer filler content, or are preparing environmental samples for elemental analysis, our equipment delivers the reliable results you demand.

Let us help you enhance your lab's capabilities. Contact our experts today to find the perfect solution for your analytical needs!

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the difference between a lab furnace and a lab oven? Choose the Right Heating Tool for Your Lab

- What is the main purpose of a furnace? A Guide to Heating, Comfort, and Material Transformation

- How is melting point affected by heating rate? Avoid Inaccurate Measurements in Your Lab

- Can calcination be done in a muffle furnace? Yes, for precise air-atmosphere heating.

- What is a furnace classified as? Understand the Two Main Types for Your Application